Efficient and environment-friendly concrete production system

A kind of concrete and environmental protection technology, applied in the field of high-efficiency and environmental protection production concrete system, can solve the problems of environmental pollution, resource waste, etc., and achieve the effect of reducing pollution and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

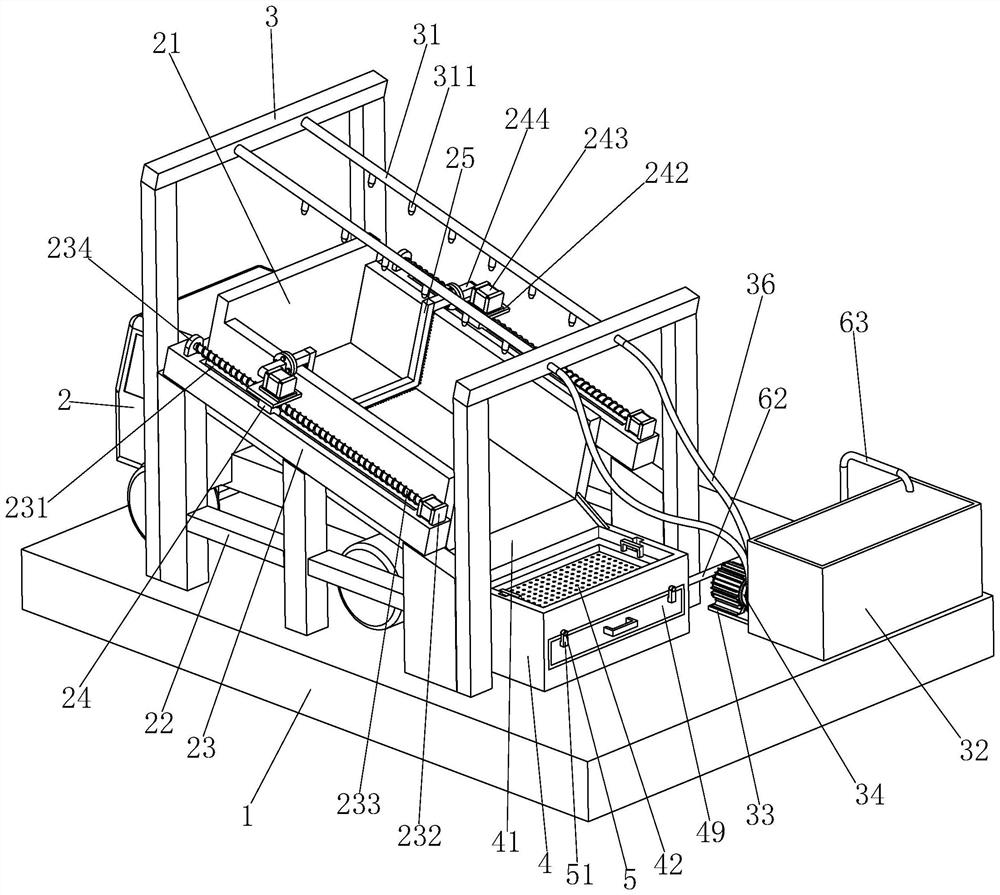

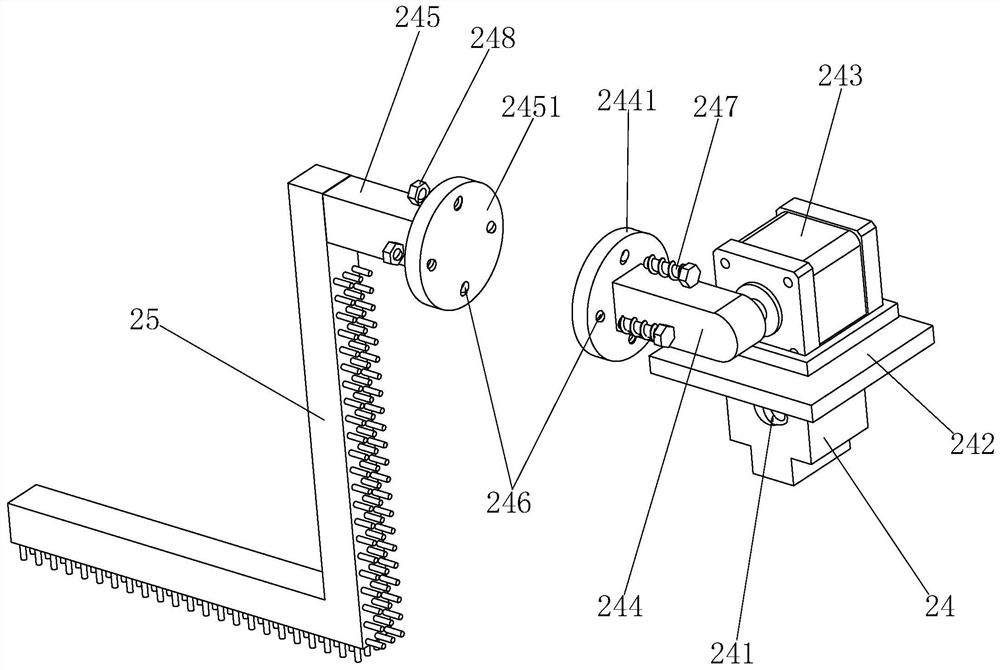

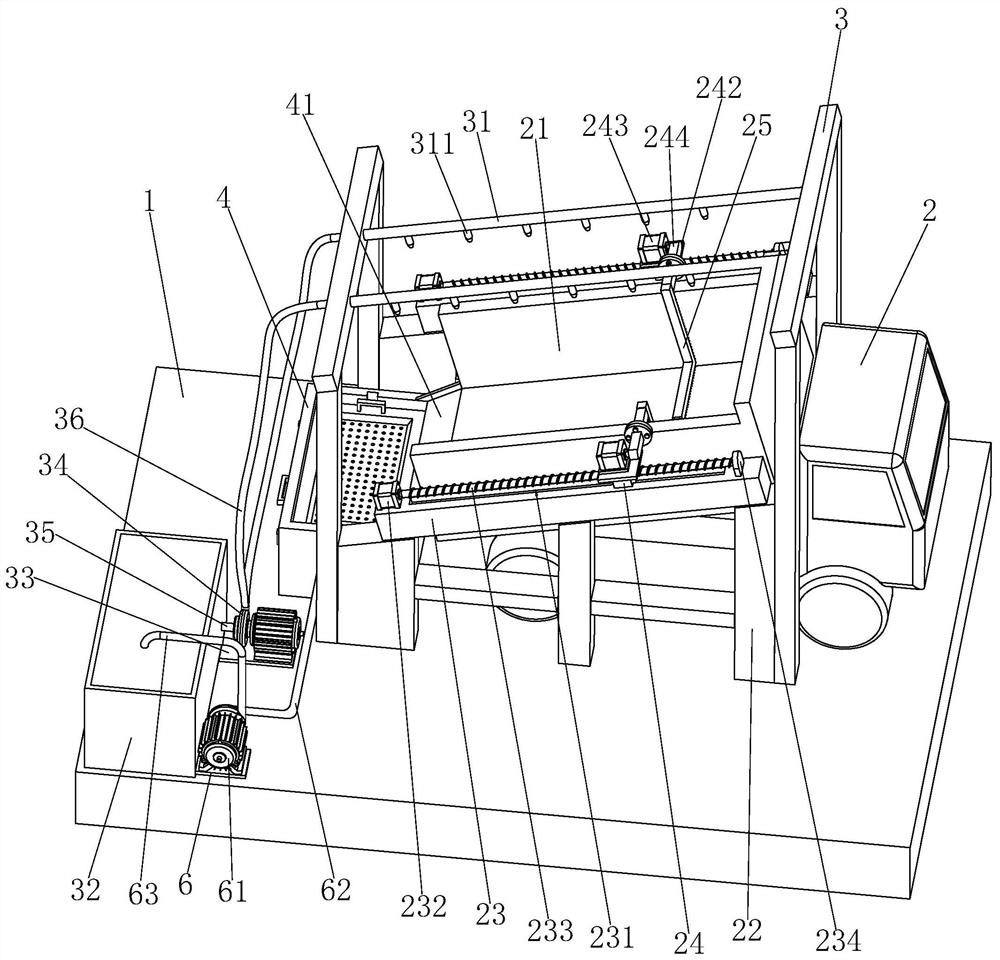

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] The embodiment of the present application discloses an efficient and environment-friendly concrete production system. refer to figure 1 , the concrete system includes a transport vehicle 2, on which a vehicle bucket 21 is installed, and the vehicle bucket 21 is used to carry ingredients for making concrete such as fine sand and stones. After the transport vehicle 2 finishes transporting the fine sand or gravel, some fine sand and gravel will often adhere to the inner side wall of the vehicle bucket 21, so in order to clean the inner side wall of the vehicle bucket 21, in this embodiment , the concrete system also includes a cleaning platform 1, a cleaning mechanism is arranged on the cleaning platform 1, when the vehicle body 21 needs to be cleaned, the transport vehicle 2 is stopped on the cleaning platform 1, and then the cleaning mechanism can The fine sand and stones ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com