Steel plate grinding device

A steel plate and support plate technology, applied in the direction of grinding drive devices, grinding machines, grinding machine parts, etc., can solve the problems of long time consumption, low work efficiency, and unreachable work efficiency, so as to improve work efficiency and meet Production requirements, reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

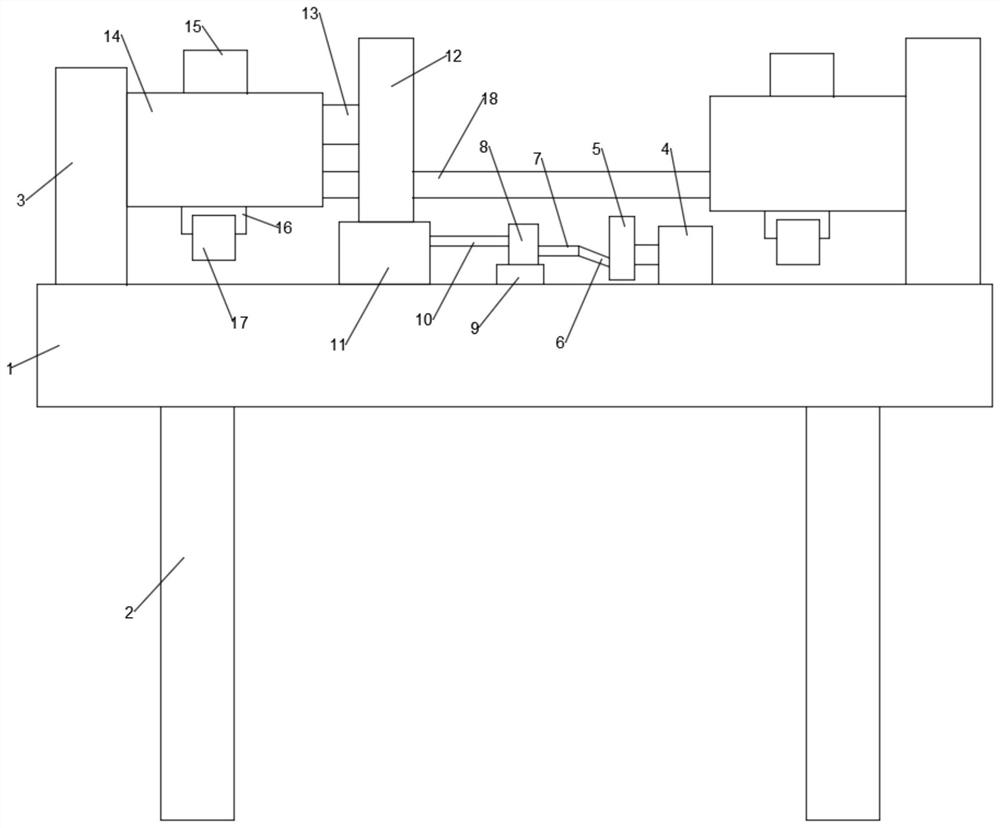

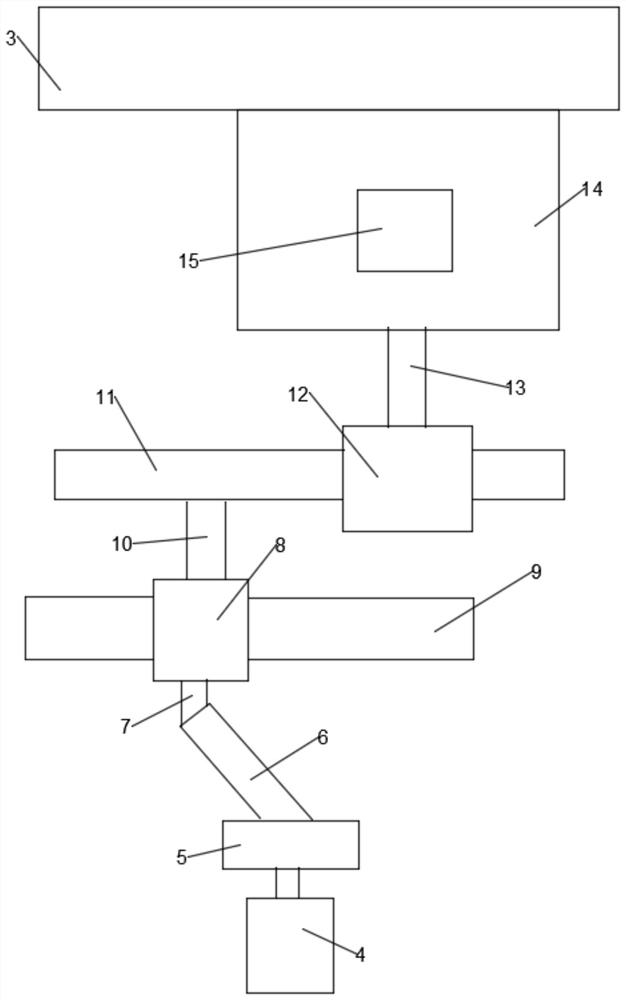

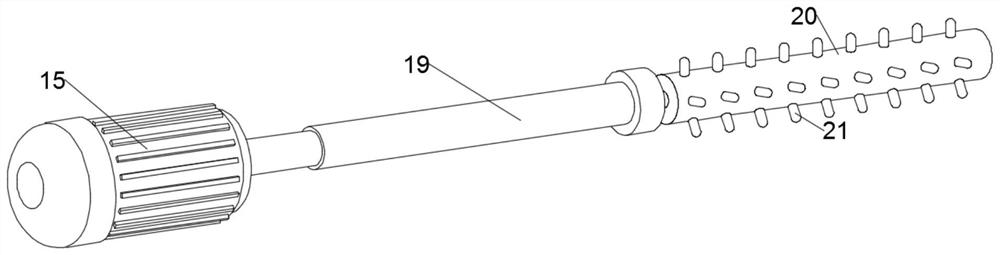

[0020] A steel plate grinding device, comprising a workbench 1, the workbench 1 is fixed on the ground through a support column 3, support plates 3 are symmetrically installed on both sides of the workbench 1, and a drive motor 4 and a slide are arranged on the upper surface of the workbench 1. Rail 9, each support plate 3 is equipped with a track near the center of the workbench 1, and a support seat 14 is slidably installed on each track, the support seat 14 can slide in the track, and the bottoms of the two support seats 14 are There is a cavity for the steel plate to pass through. The rusty steel plate can pass the part that does not need to be polished through the cavity, so as to avoid the product quality problem caused by the grinding assembly 17 grinding it. The fourth Connecting rod 18 is fixedly connected, and each support base 14 tops are all equipped with grinding motor 15, and the output end of each grinding motor 15 is all rotatably connected with grinding assembl...

Embodiment 2

[0024] A steel plate grinding device, comprising a workbench 1, the workbench 1 is fixed on the ground through a support column 3, support plates 3 are symmetrically installed on both sides of the workbench 1, and a drive motor 4 and a slide are arranged on the upper surface of the workbench 1. Rail 9, each support plate 3 is equipped with a track near the center of the workbench 1, and a support seat 14 is slidably installed on each track, and the bottoms of the two support seats 14 are provided with cavities, and the two support seats 14 is fixedly connected by the fourth connecting rod 18, and each supporting base 14 tops are equipped with a grinding motor 15, and the output end of each grinding motor 15 is rotatably connected with a grinding assembly 17, and the output end of the driving motor 4 is rotatably connected with a grinding assembly 17. The runner 5 is fixedly connected with the first connecting rod 6, the first connecting rod 6 is fixedly connected with the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com