Multi-positioning printing method for paperboard color printing

A printing method and cardboard technology, applied in printing, paper/cardboard containers, papermaking, etc., can solve the problems of edge ghosting of printing patterns, accumulation of printing errors, blurring, etc., and achieve the effect of clear lines, improved precision and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

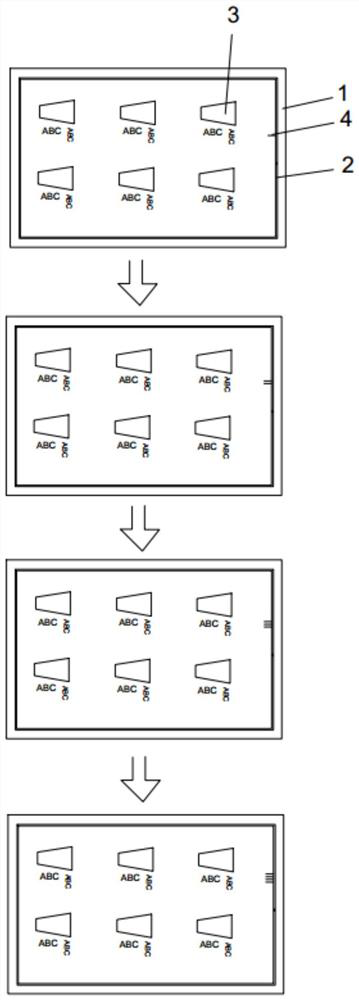

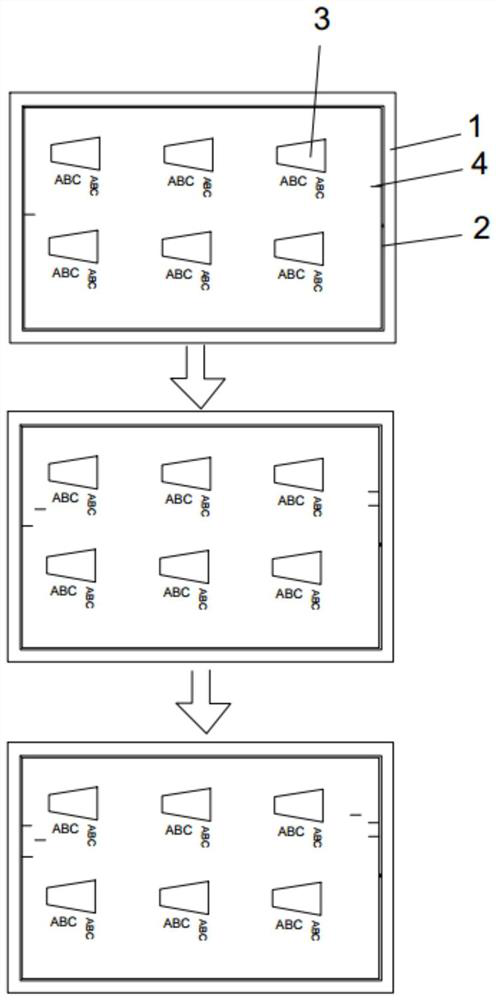

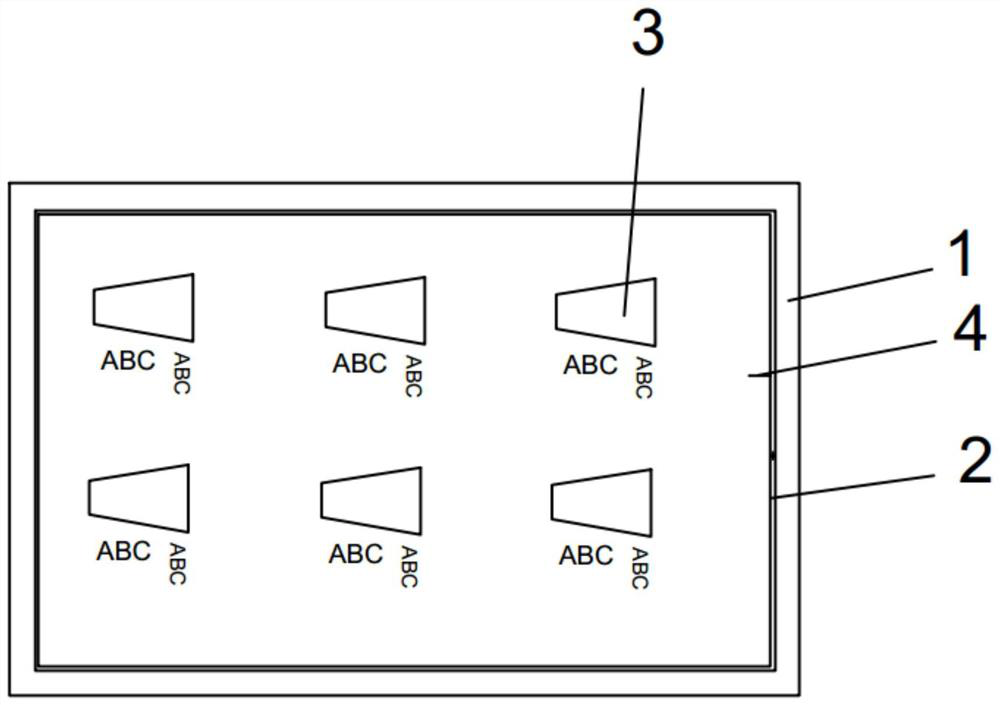

[0017] Example 1, a multi-positioning printing method for cardboard color printing. In the multi-color printing process, when printing a single-layer printing pattern, several positioning lines are printed simultaneously outside the printing pattern. The positioning line printed in the previous printing step is used as the reference for positioning, the printing positions of the positioning line are equally spaced, and the printing position of the positioning line is inside the cardboard printing frame, such as figure 1 as shown, figure 1 It shows the five-color printing process of a piece of cardboard. During the first pass of printing, the yellow background color and the first positioning line are printed on the cardboard, and then the cardboard is driven by the rubber roller to the second pass of printing. The second pass of printing The printing equipment at the location is positioned by detecting the first positioning line, and after positioning, the magenta layer is prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com