Sloping roof counterweight-free basket mounting and dismounting method

The technology of a counterweight hanging basket and an installation method is applied in the direction of house structure support, house structure support, scaffolding of house structure support, etc., and can solve the problems of lower installation efficiency and installation inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

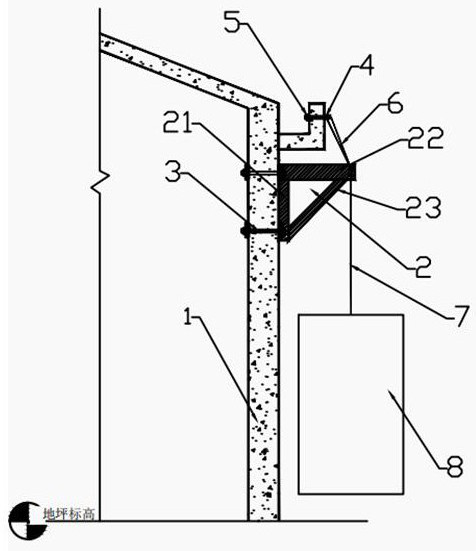

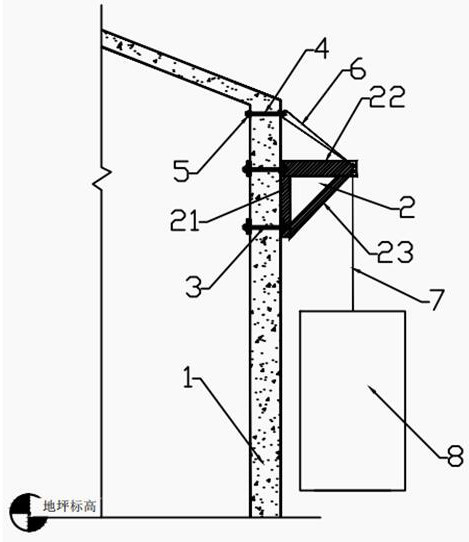

[0018] As shown in the figure, the installation method of the sloping roof without counterweight hanging basket provided by this embodiment includes the following steps: S1, during the construction of the top outer wall, pre-embed pipes at the upper end of the gutter and / or shear wall 1 ( During specific implementation, the pipes can also be pre-embedded on the shear column or structural beam according to the setting position of the hanging basket) to form multiple rows of reserved holes, and the reserved holes are provided with at least three rows, each row has at least two, and The reserved holes in the upper and lower rows correspond one by one; S2, pre-preparation, prefabricate the suspension bracket 2 and the suspension ring 4, and prepare multiple sets of anchors 3, nuts 5 and steel wire ropes 6; the suspension bracket 2 is a triangular steel bracket, The lifting ring 4 is U-shaped and is composed of a left connecting rod, a right connecting rod and an arc-shaped connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com