Plug, socket and electric connection device with plug and socket

A technology for electrical connection devices and sockets, which is applied to parts of connection devices, devices to prevent contact with live contacts, and connections. It can solve the problems of electrode surface pollution, deformation of safety protection bosses, and complex structures. Performance and load capacity, meet safety requirements, increase the effect of matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

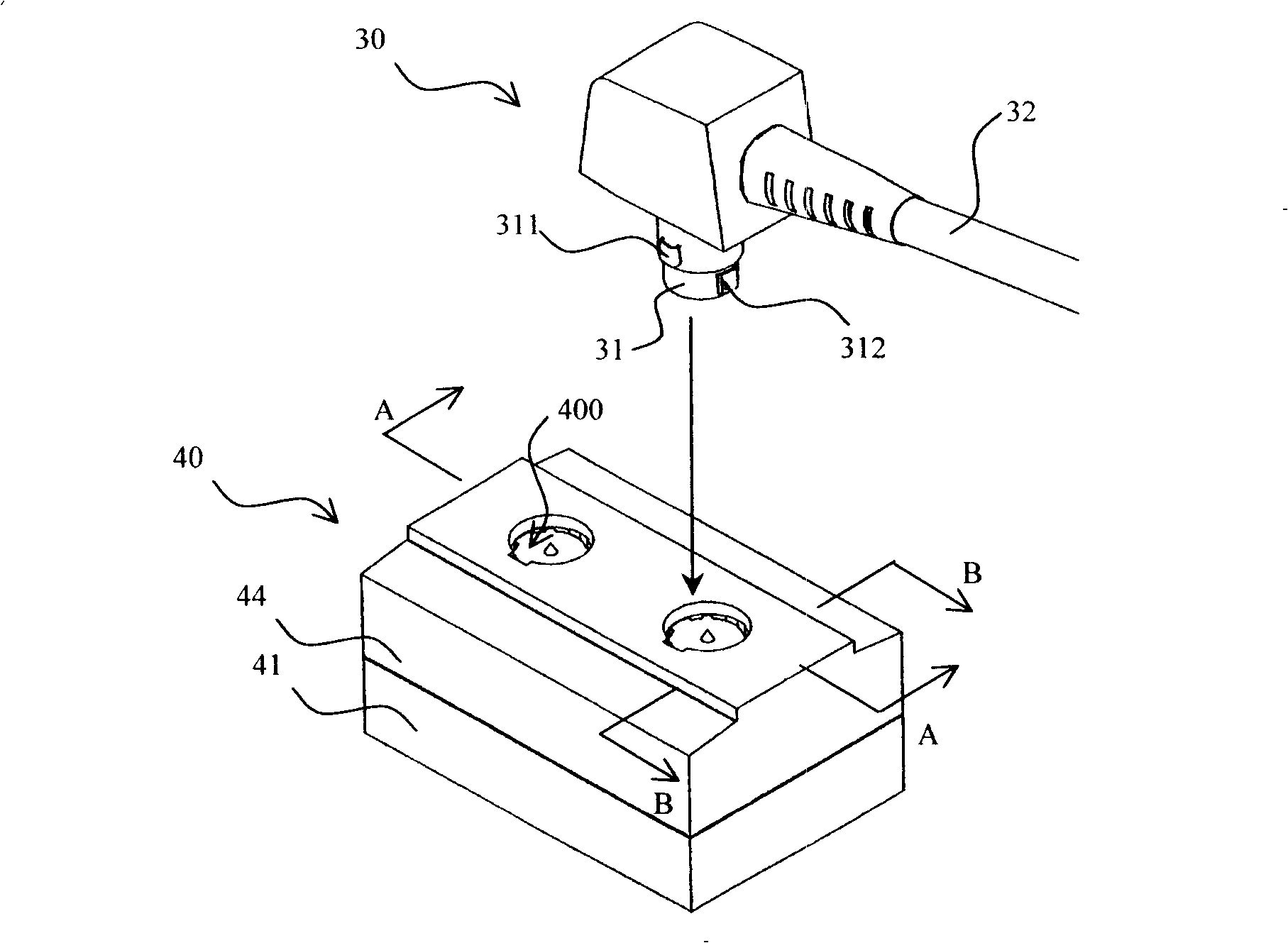

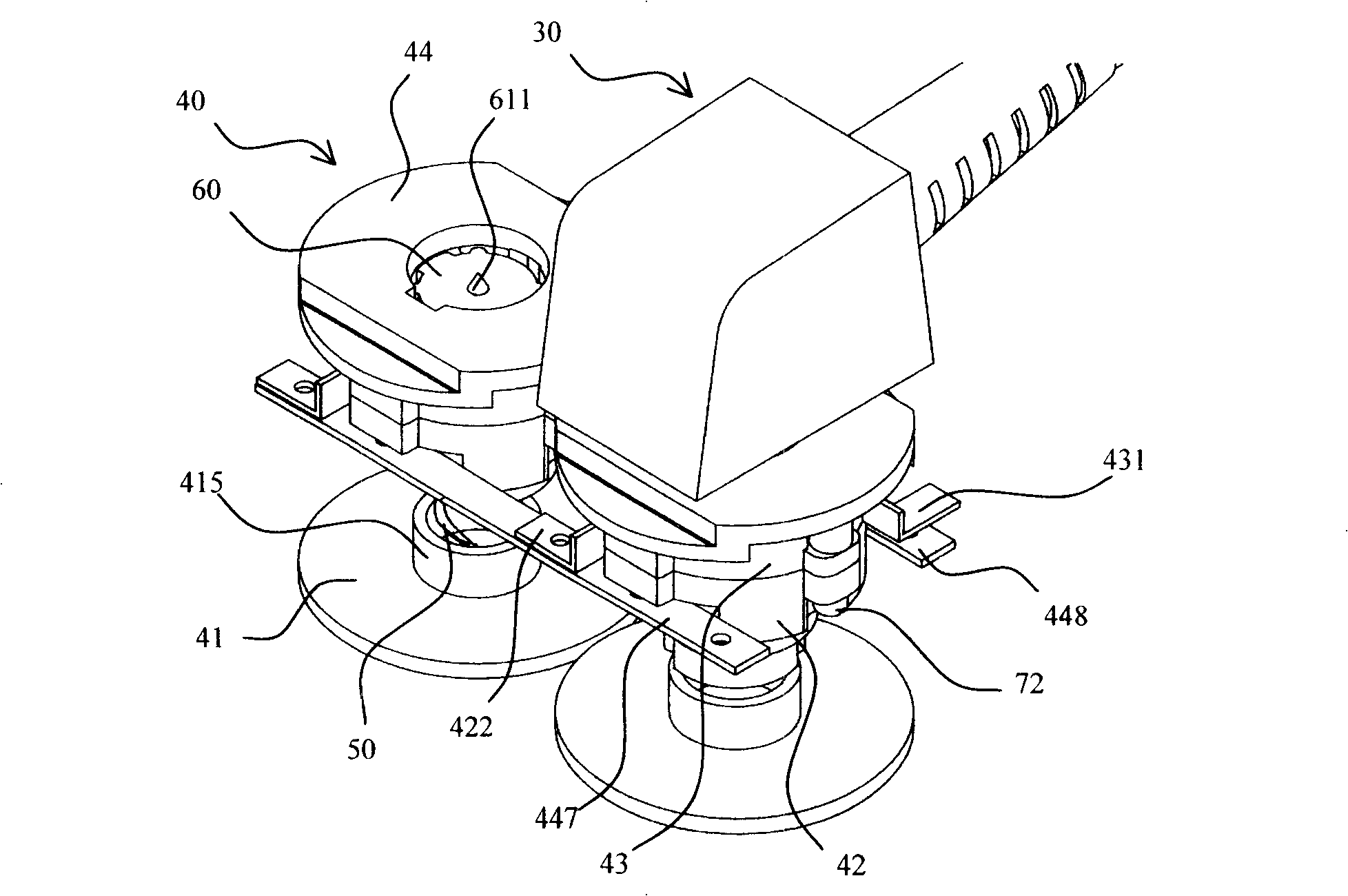

[0087] Combine below Figure 2A ~ Figure 5B , illustrating a preferred electrical connection device in the form of a wiring board and an electrical connection method thereof in the present invention.

[0088] Such as Figure 2A-2C As shown, the electrical connection device of the present invention includes a plug 30 and a socket 40, wherein there are two sockets 40 . Such as Figure 2A As shown, the outer wall of the plug 31 of the plug 30 protrudes outwards and is provided with a first metal contact connected to the cable 32, which includes a first ground electrode 311 and two oppositely arranged first power electrodes 312, 313 (specifically see Figure 5B ), and the first ground electrode 311 and the first power supply electrodes 312, 313 are formed with a first contact surface inclined at a first predetermined angle (as shown in FIGS. 5A and 5B ).

[0089] Such as Figure 2B , 2C shown, combined with Figure 2A, The socket 40 includes a socket base 41, a power base 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com