Steam injection and oil extraction integrated lifting device for offshore heavy-oil thermal production well and operation method of steam injection and oil extraction integrated lifting device

A lifting device, a technology for thermal recovery of heavy oil, which is applied to the components of a pumping device for elastic fluid, production fluid, and earth-moving drilling, etc. Solving problems such as cold damage of oil layer, to achieve the effect of improving development efficiency, reducing operating costs, and increasing peak oil production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

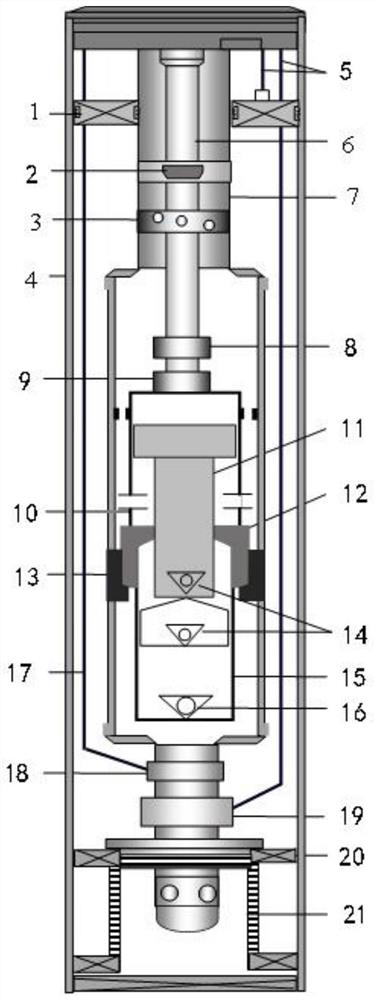

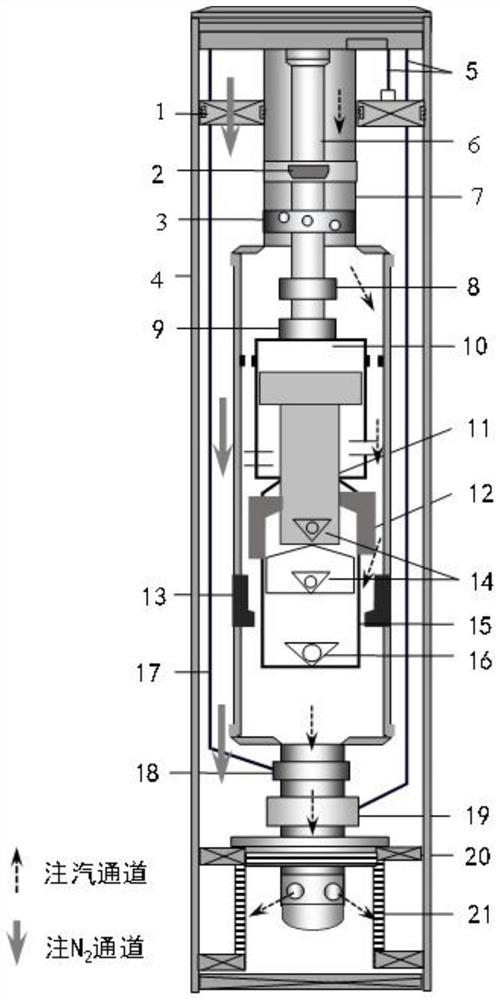

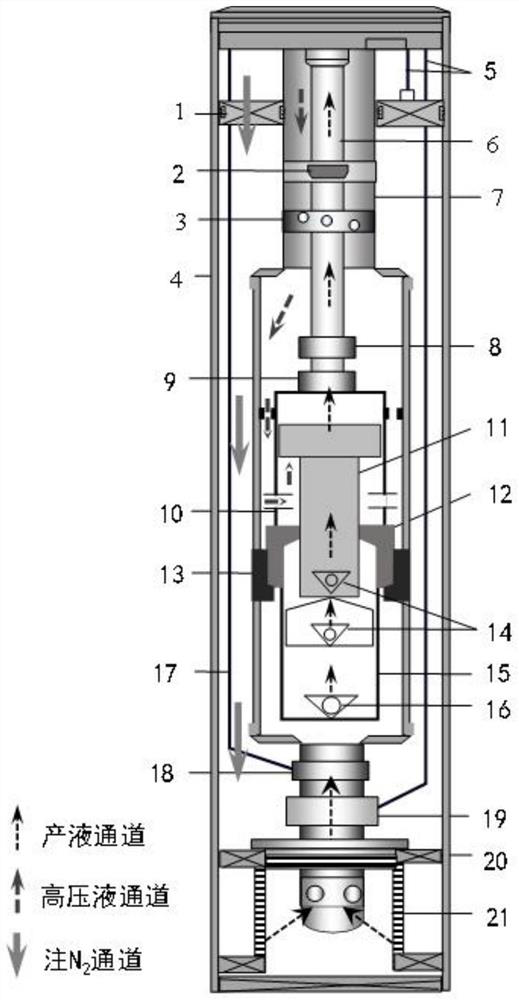

[0044] Such as figure 1 As shown, the present invention firstly provides an integrated lifting device for steam injection and oil production in offshore heavy oil thermal recovery wells. 4. Hydraulic control pipeline 5, power pipe 6, heat insulation oil pipe 7, oil drain valve 8, high temperature downhole docking device 9, upper cylinder body 10, reciprocating plunger 11, positioning seal 12, working cylinder 13, swimming valve 14 , lower cylinder body 15, fixed valve 16, steel pipe cable 17, pressure measuring / temperature measuring device 18, high temperature deep well safety valve 19, top packer 20, sand control section 21.

[0045] The inside of the production casing 3 is provided with a heat insulating oil pipe 7, and the annular space between the heat insulating oil pipe 7 and the production casing 3 is installed with a cable packer 1, and the heat insulating oil pipe 7 is provided with a power pipe 6, and the power pipe 6 An oil drain valve 8 and a high-temperature dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bevel | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com