Protective cover capable of prolonging rubber outlet time of natural rubber bark cutting

A technology of natural rubber and protective cover, applied in the field of protective cover, can solve the problems of affecting the collection process of gum, rapid solidification, mixed with leaves and impurities, etc., and achieve the effect of prolonging the frequency of tapping, reducing damage and increasing sliding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

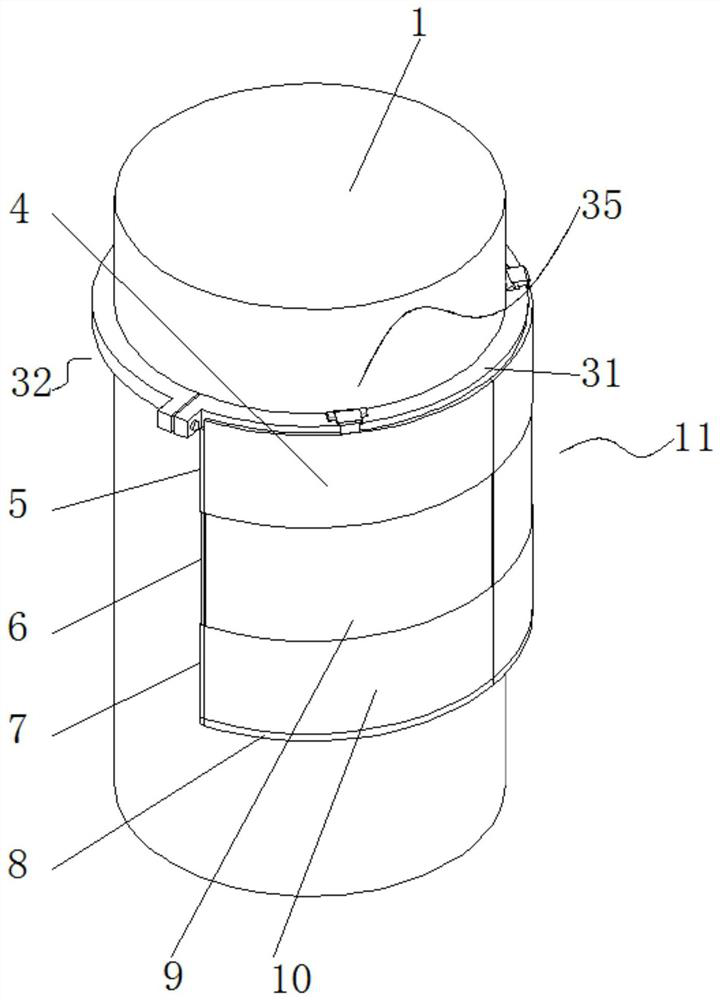

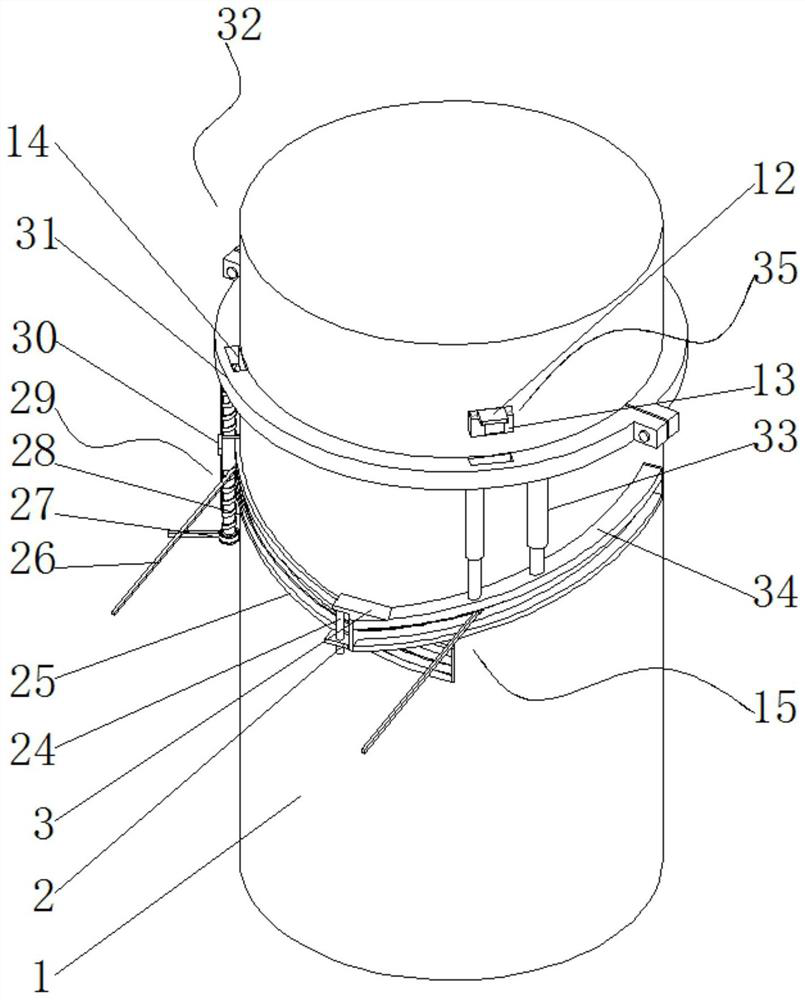

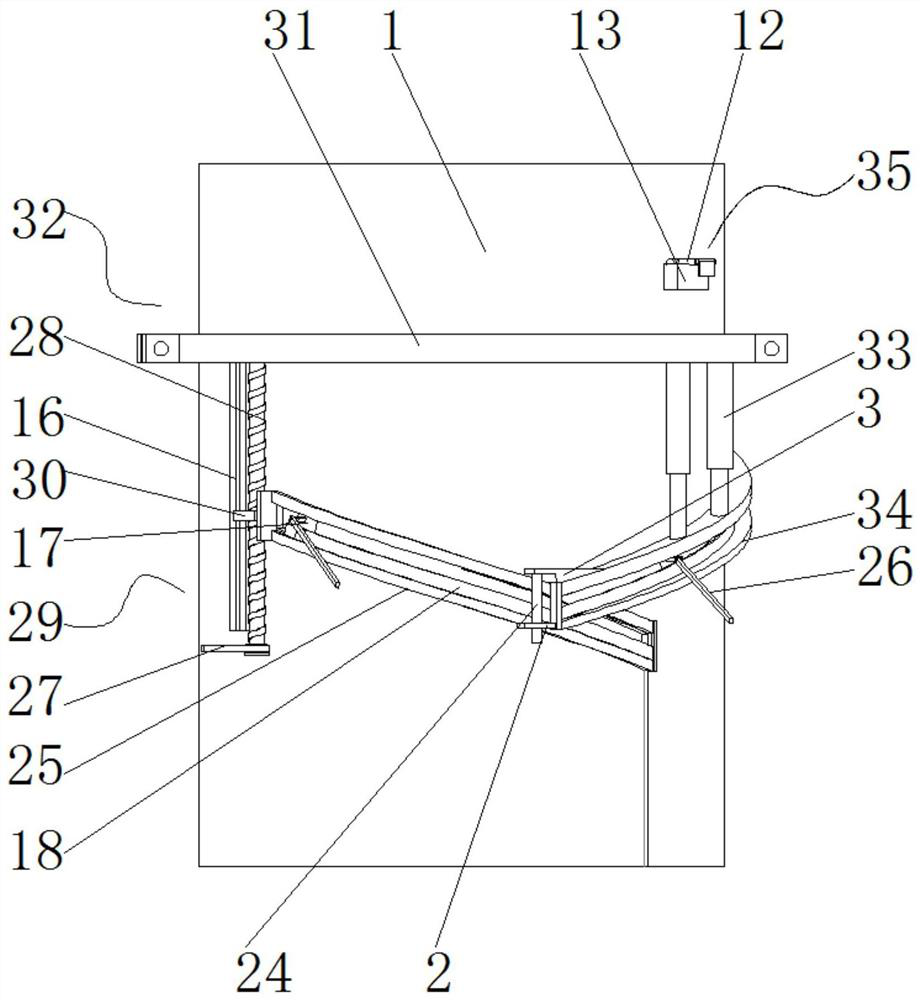

[0026] The embodiment of the present invention provides a kind of protective cover that can prolong the glue-out time of cutting natural rubber bark, such as Figure 1-8 As shown, it is set on a rubber tree 1 and includes a fixing component 32 and two protection components 11 . The fixing assembly 32 is arranged on the rubber tree 1, and the two protection assemblies 11 are hinged on the rubber tree 1 by the plug assembly 35. One sides of the two protection components 11 are in contact with each other. Protection assembly 11 comprises arc baffle plate one 4, arc baffle plate two 10, curved panel 9, slide strip plate 6, side baffle plate one 5, side baffle plate two 7 and bottom surface baffle plate 8. The top of the curved baffle 4 is hinged with the plug-in assembly 35 , and the bottom is sleeved on the curved panel 9 . The top of the curved baffle plate 2 10 is sleeved on the curved panel 9 , and the side baffle plate 1 5 is arranged on the side of the curved baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com