A variable stiffness linear drive device and a variable stiffness method

A linear drive, linear drive technology, applied in the direction of manufacturing tools, claw arms, manipulators, etc., can solve the problems of high cost, large volume, limited available scenarios, etc., to achieve the effect of high space utilization and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

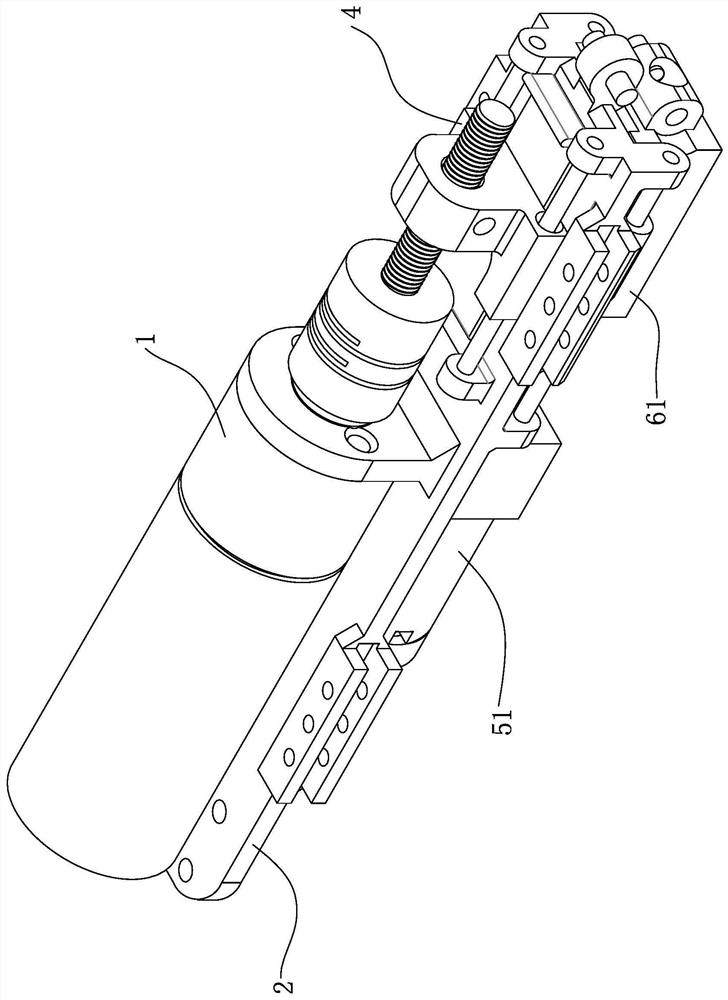

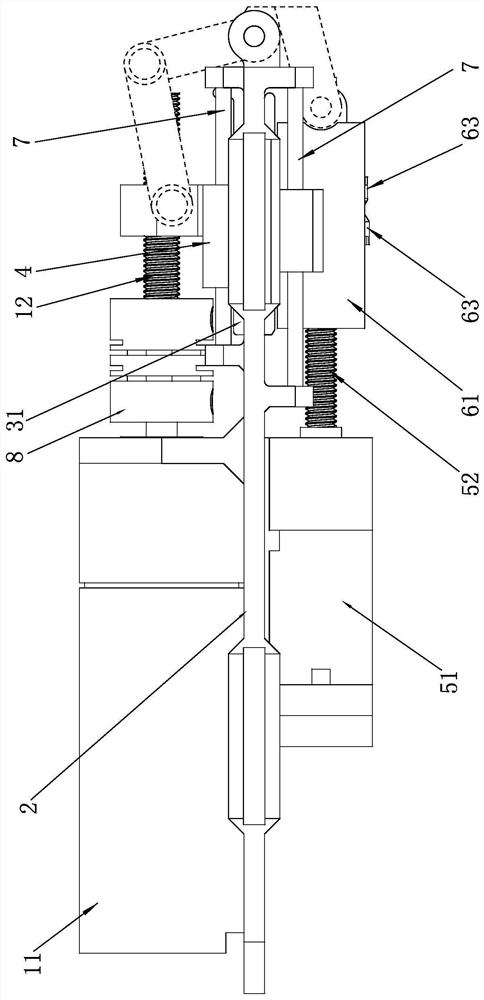

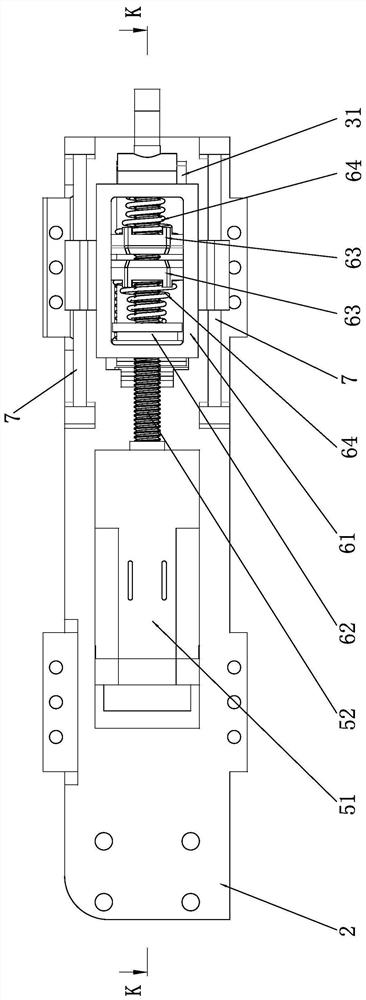

[0039] see Figure 1-Figure 7 As shown, a variable stiffness linear drive device of this embodiment includes a first linear drive 1, a second linear drive, a variable stiffness module, a tongue assembly and a frame 2;

[0040] The first linear driver 1 is arranged on one side of the frame 2, and the first linear driver 1 drives the slider 4 to move on the frame 2; the frame 2 is provided with a touch tongue assembly, and the touch tongue assembly includes a touch tongue 31 and Spring 32; the two ends of the spring 32 lean against the touch tongue 31 and the frame 2, and the touch tongue 31 can be driven and moved by the slider 4;

[0041] The second linear driver includes a second screw 52 driven by a second motor 51, the second motor 51 is fixed on the other side of the frame 2, and the variable stiffness module includes a module seat 61, an axial thrust rotating member 62, two Drive nut 63 and two non-linear springs 64, the second screw mandrel 52 is covered with slidable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com