Lighter piezoelectric ignition device plastic body full-automatic sprue stripping machine

A technology of ignition device and plastic body, which is applied in the field of injection molding separation equipment, can solve the problems of high labor intensity, inability to guarantee the smooth peeling surface of terminal products and connecting plates, and high defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

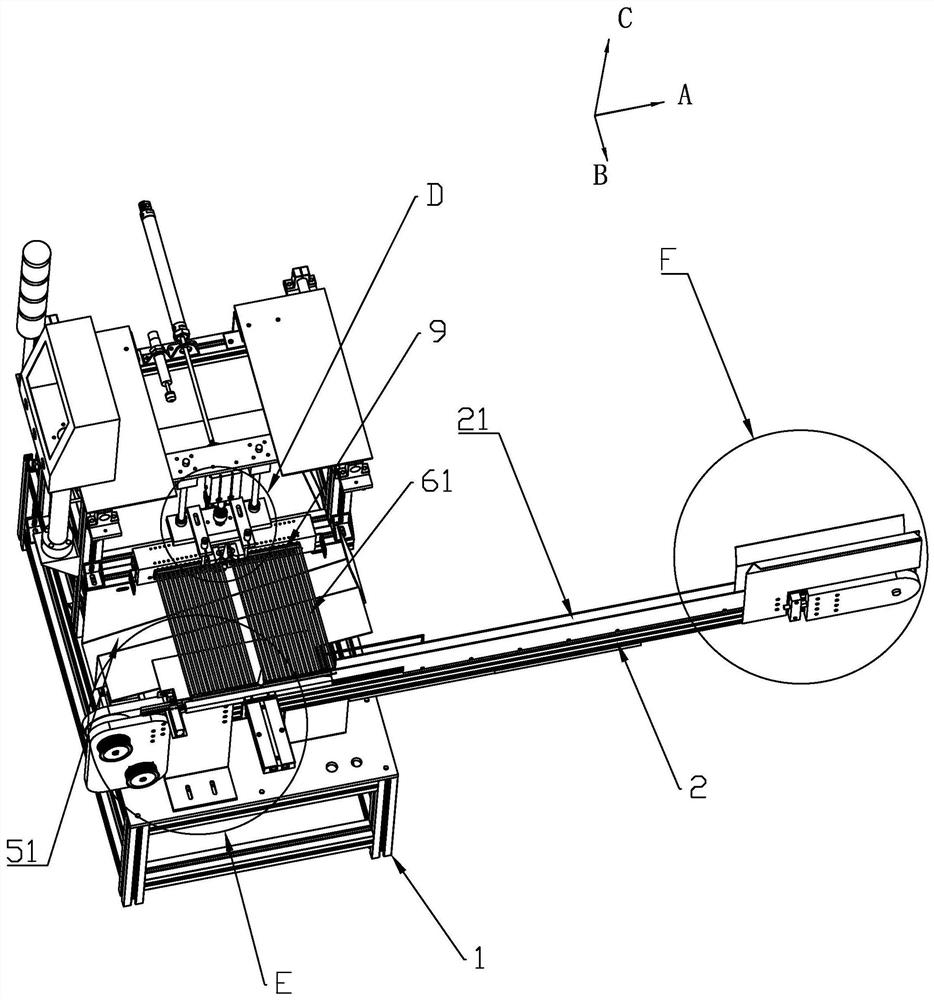

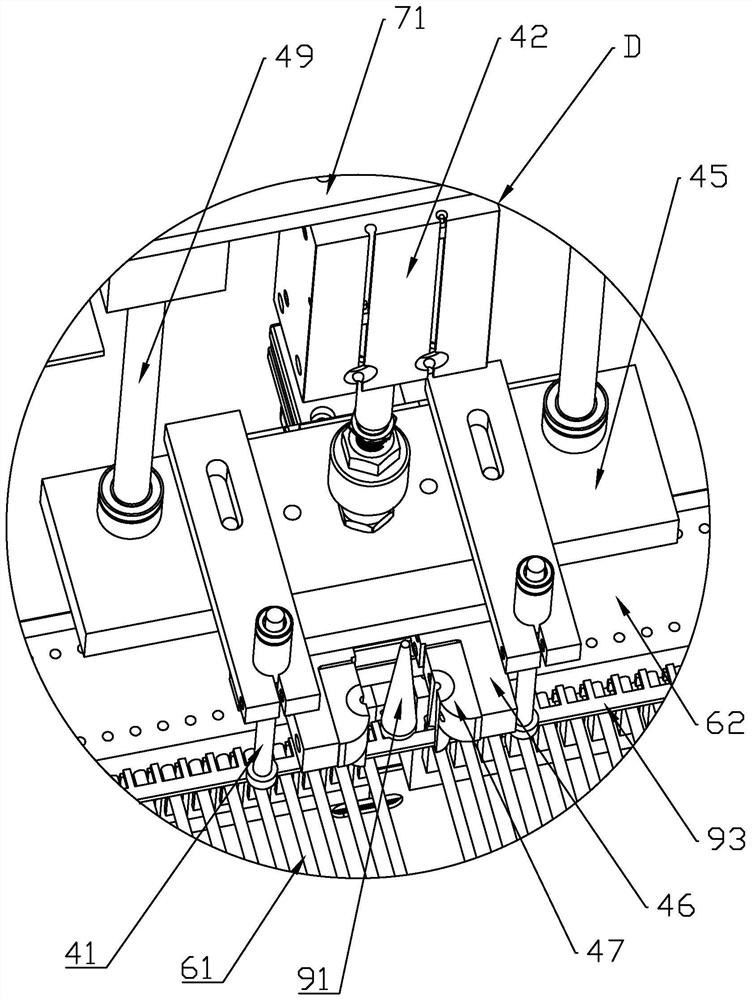

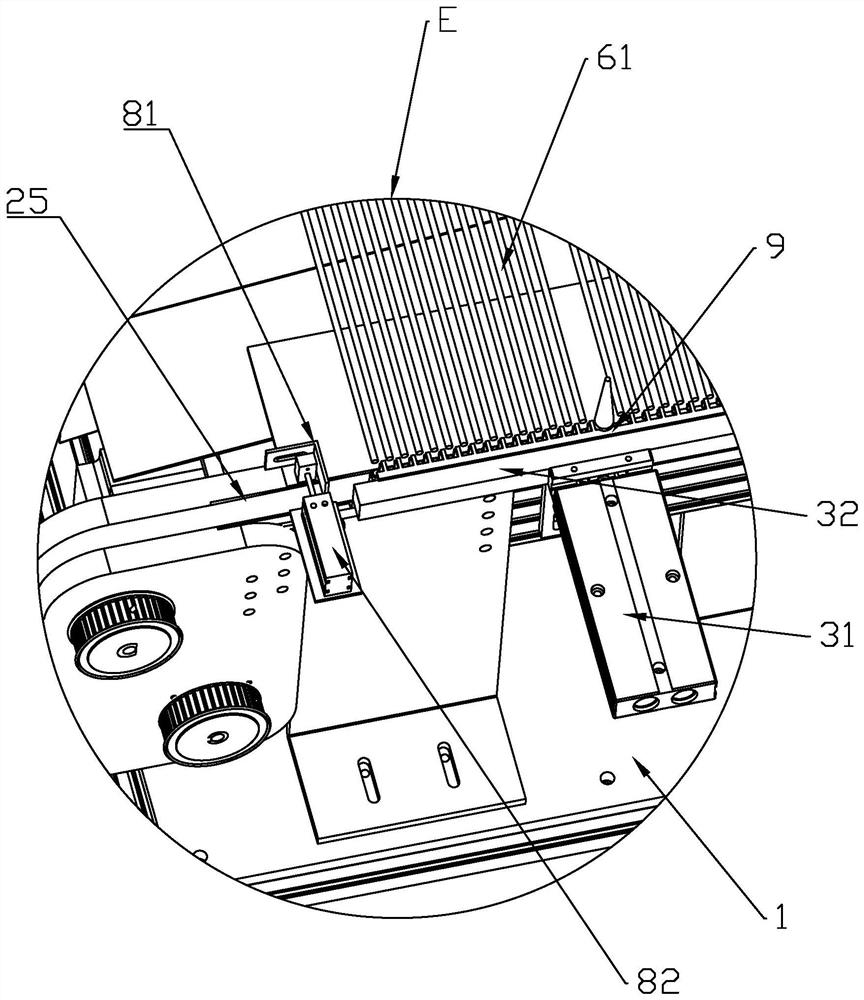

[0037] like Figure 1-Figure 11 As shown in the figure, an automatic gate separation and peeling machine for the plastic body of a piezoelectric ignition device of a lighter includes a frame 1, and the frame 1 is provided with a feeding mechanism 2, a propulsion mechanism 3, a separation mechanism 4 and a feeding mechanism. The mechanism 2 can transfer the initial product 9 to the propulsion mechanism 3, and between the propulsion mechanism 3 and the separation mechanism 4, there are several supporting rods 61 arranged side by side and spaced apart. The connecting plate 93 of the product 9, the pushing mechanism 3 can push the initial product 9 to the separating mechanism 4 in the longitudinal direction, and the separating mechanism includes the pressing rod 41, the first cylinder 42, the first push plate 43 and the second cylinder 44, the first The cylinder 42 is installed on the frame 1, the pressure rod 41 and the telescopic rod of the first cylinder 42 are arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com