Automatic material taking device for injection mold

A technology of automatic material retrieving and injection molding, which is applied to household appliances, other household appliances, cleaning methods and appliances, etc., can solve problems such as low efficiency, pollute the environment, and threaten the physical and mental health of staff, so as to improve the efficiency of retrieving materials, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

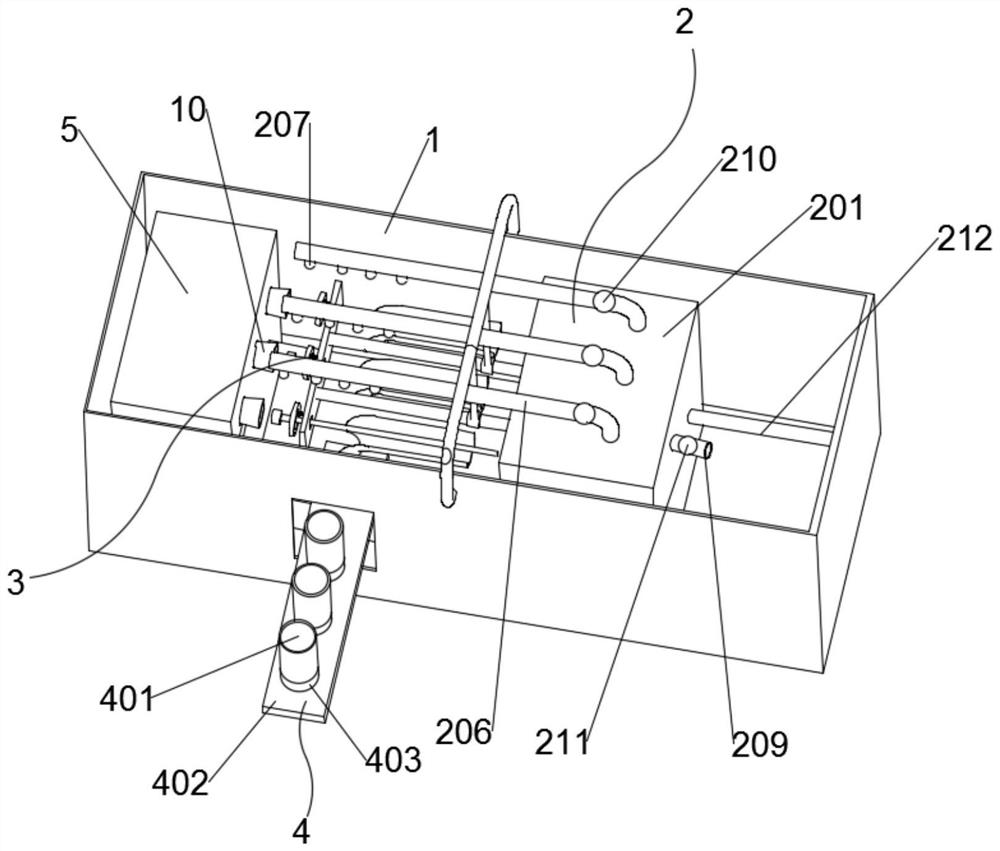

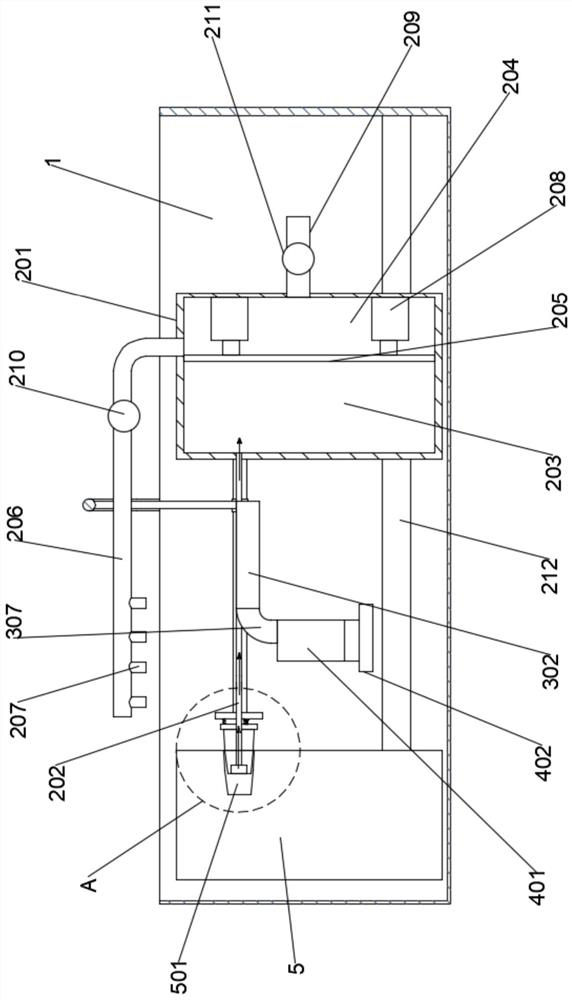

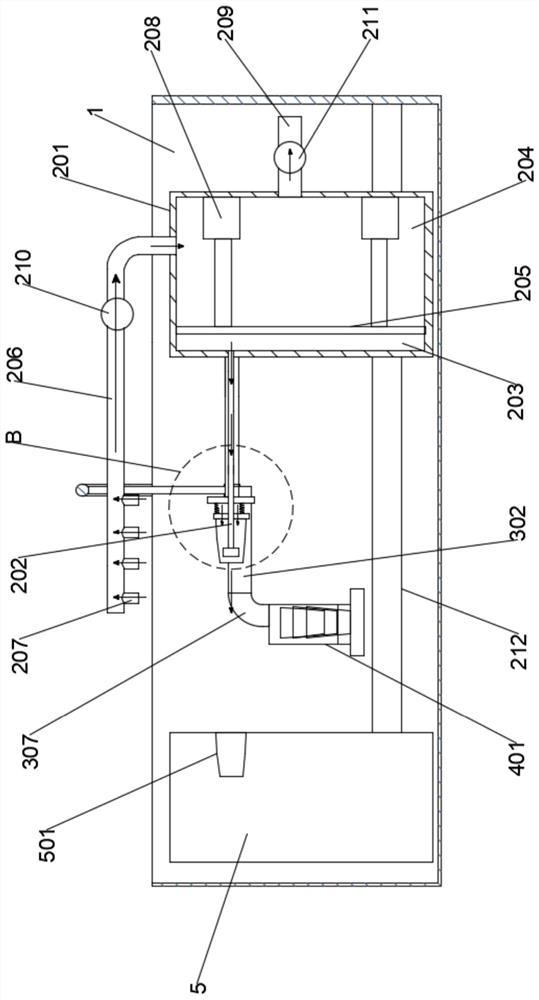

[0029] Such as Figure 1 to Figure 5 As shown, the present invention provides an automatic retrieving device for an injection mold, which can improve the retrieving efficiency of the cup-packed workpiece 10, and can quickly cool the cup-packed workpiece 10 after demoulding, and remove the heat generated during the heat dissipation process. Harmful gases are collected in time to reduce environmental pollution. specific:

[0030] The automatic retrieving device includes a working box 1 with an upper end open, a mold set, a moving material suction mechanism 2 , a material guide assembly 3 and a material loading assembly 4 .

[0031] Wherein, the mold group is installed on the inner side of the working box 1, including a mold body 5 for injection mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap