Bionic ocean buoy structure

A bionic and marine technology, applied in buoys, special-purpose ships, transportation and packaging, etc., can solve the problems of insufficient power supply, resistance to collision, troubles, etc., and achieve the effect of stable floating body base and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

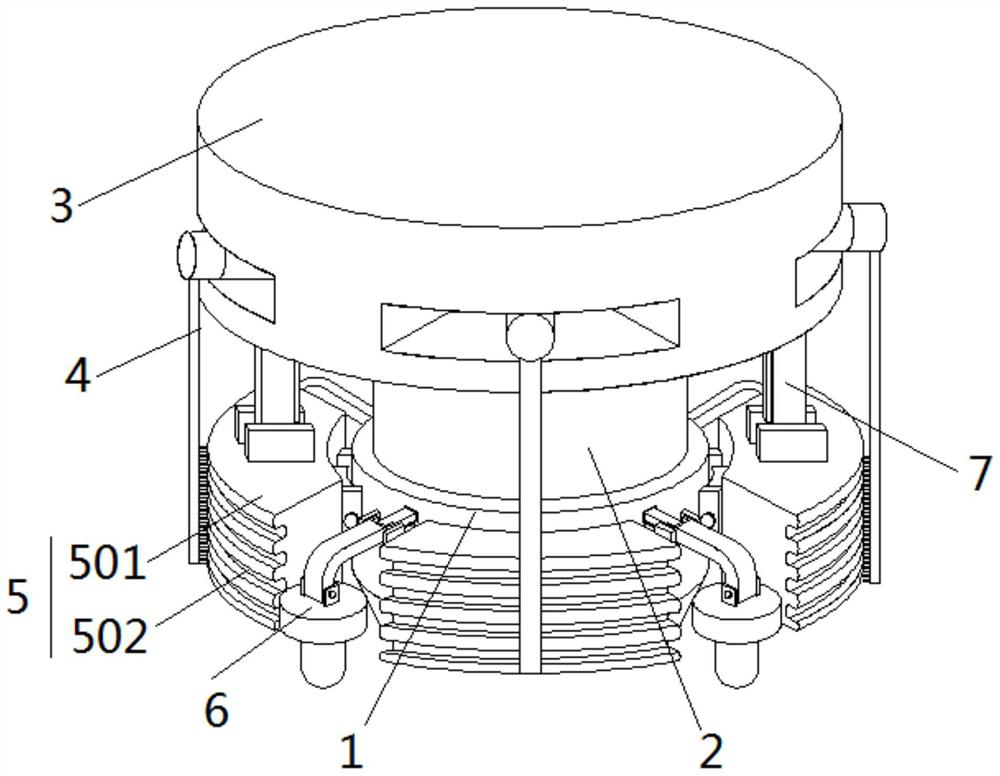

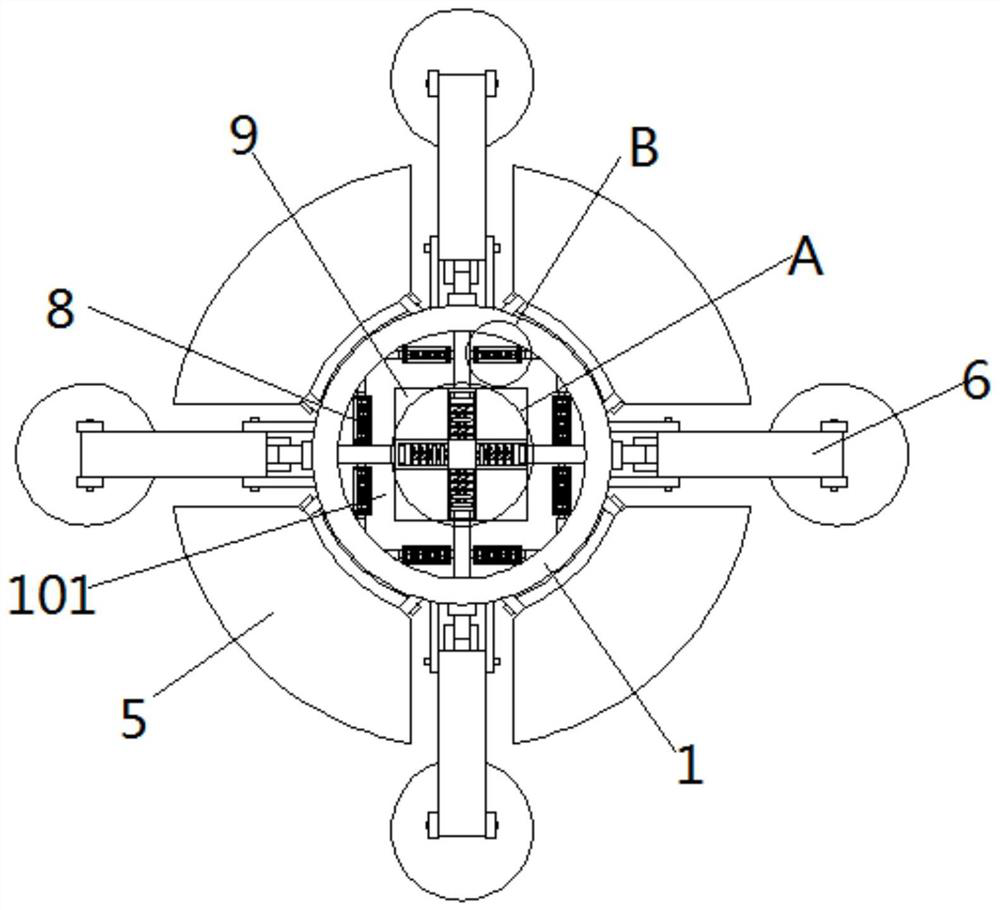

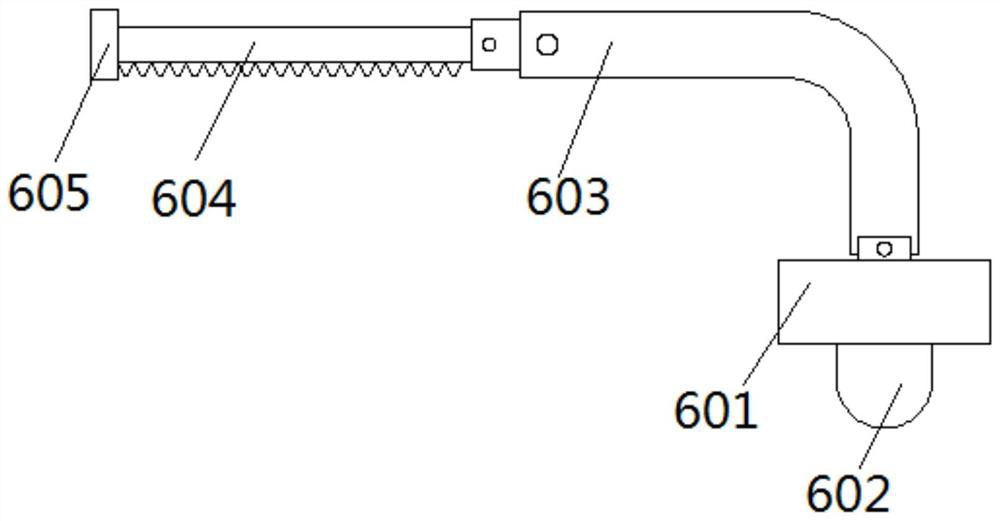

[0033] as attached figure 1 to attach Figure 9Shown: a bionic marine buoy structure, including a buoy base 1, a storage box 2, a support platform 3, a scrubbing device 4, a balancing device 5, a driving device 6, a driving assembly 7, a power generating device 8, a support reset device 9, a transmission Component 11, a No. 1 hollow groove 101 is provided inside the floating body base 1, and a supporting reset device 9 is fixedly connected to the center of the No. Balance devices 5 are installed equidistantly around the outside of the base 1, and the outside of the floating body base 1 is located in the gap between the balance devices 5 and is movably connected with a driving device 6. The extension section of the device 6 is connected to the power generating device 8 by transmission. The center position of the top of the floating body base 1 is fixedly connected to the storage box 2. The storage box 2 is equipped with a battery inside. The battery is electrically connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com