AGV centering table mechanism

A technology of centering platform and materials, which is applied in the field of AGV centering mechanism, which can solve the problem of high utilization rate of production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

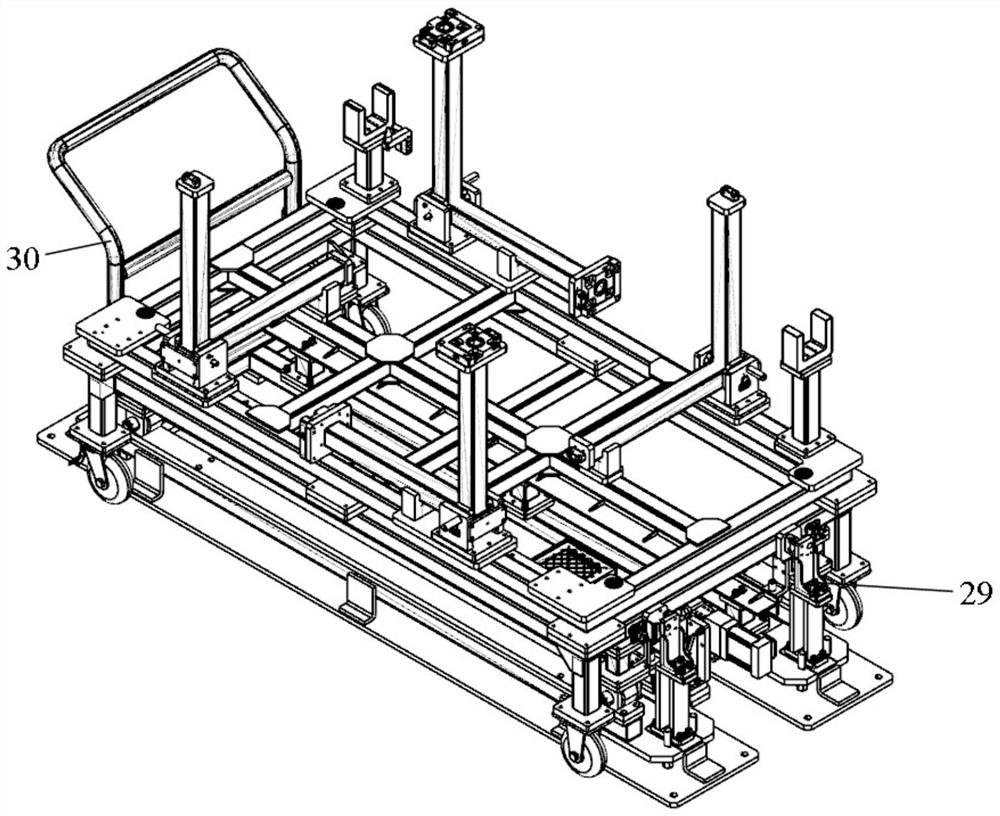

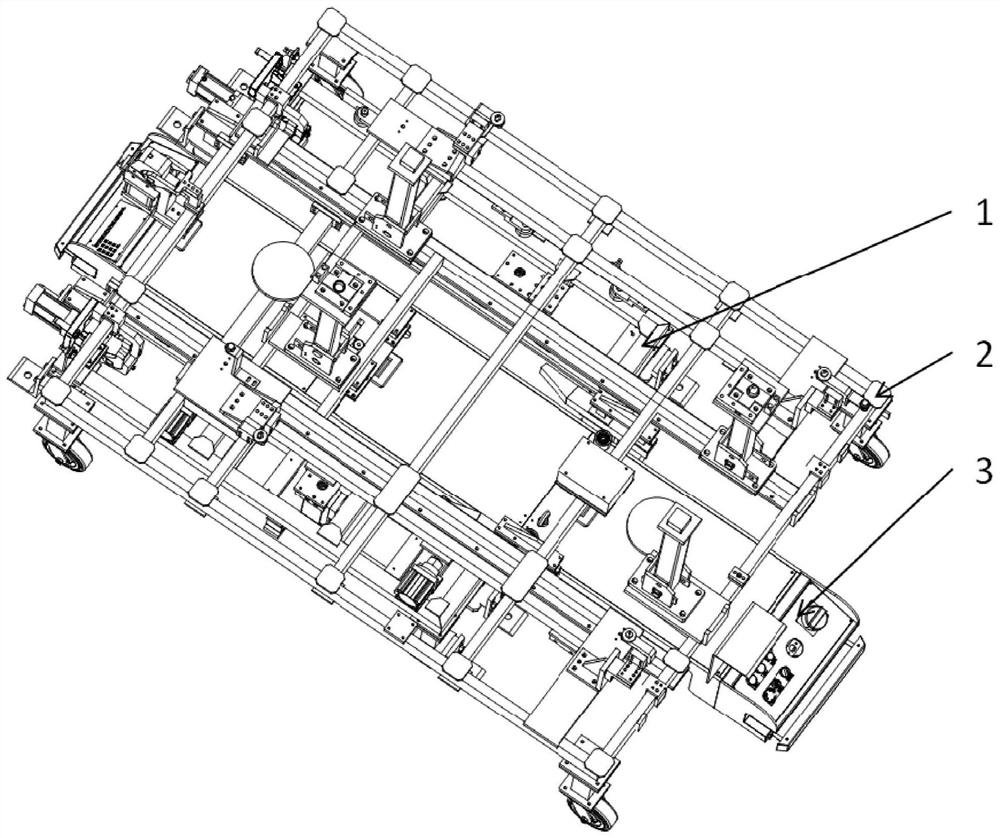

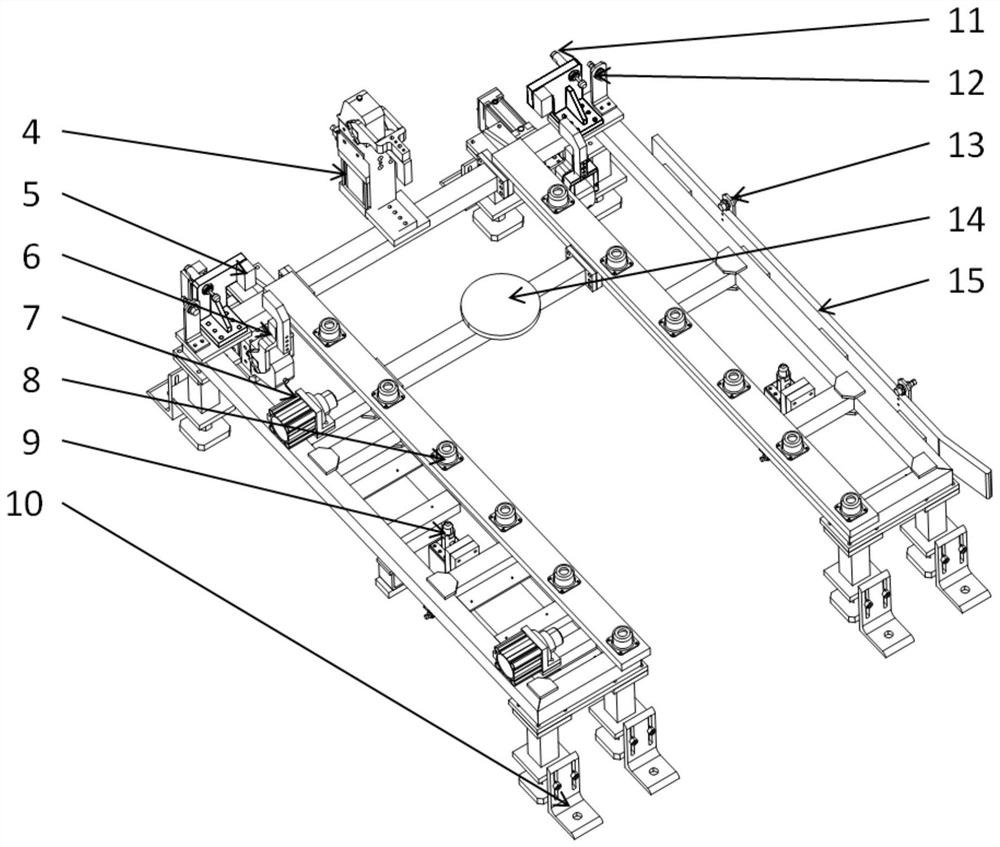

[0035] Combine below Figure 2 to Figure 5 , a further detailed description will be given to an AGV of the present invention for the mid-stage mechanism.

[0036] For an AGV centering platform mechanism of the present invention, please refer to Figure 2 to Figure 5, including a centering platform base 1, a centering platform material trolley 2 and an AGV centering platform trolley 3, the centering platform base 1 is detachably fixed on the ground or an installation surface, and the AGV centering platform trolley 3 is movable It is installed in the middle of the centering platform base 1 from front to back, and the centering platform material trolley 2 is erected directly above the AGV centering platform trolley and the centering platform base 1, and the centering platform The material trolley 2 is releasably fixedly connected with the AGV centering platform trolley and the centering platform base 1 respectively, and the part assembly is releasably fixed on the centering plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com