A textile dust surround removal device for textile fabric processing

A technology for textile fabrics and textile dust, which is applied in the field of textile dust surround-type removal devices, and can solve problems such as textile dust flying, textile dust legacy, and worker injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

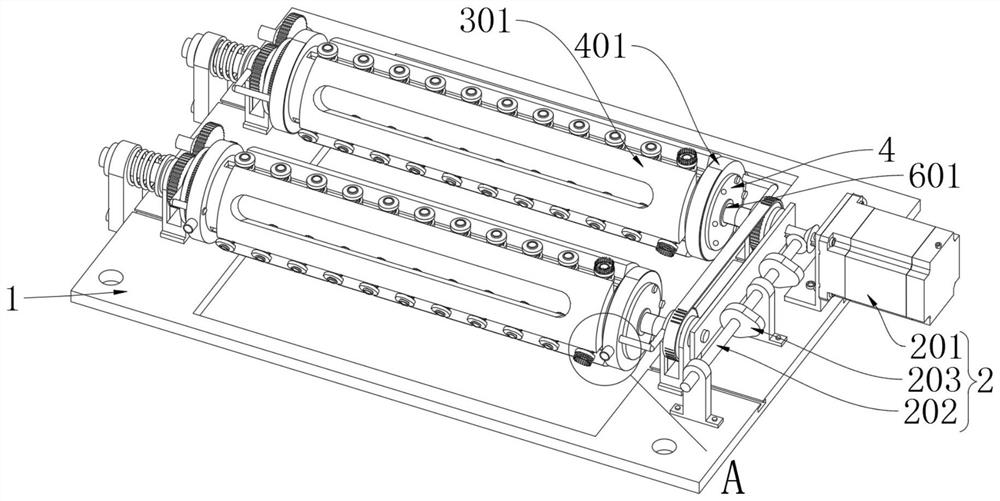

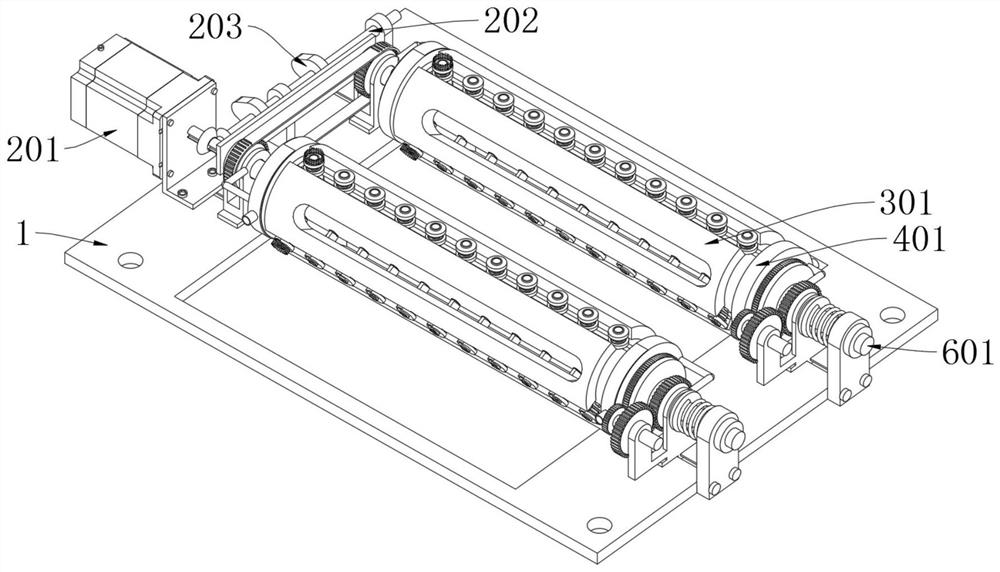

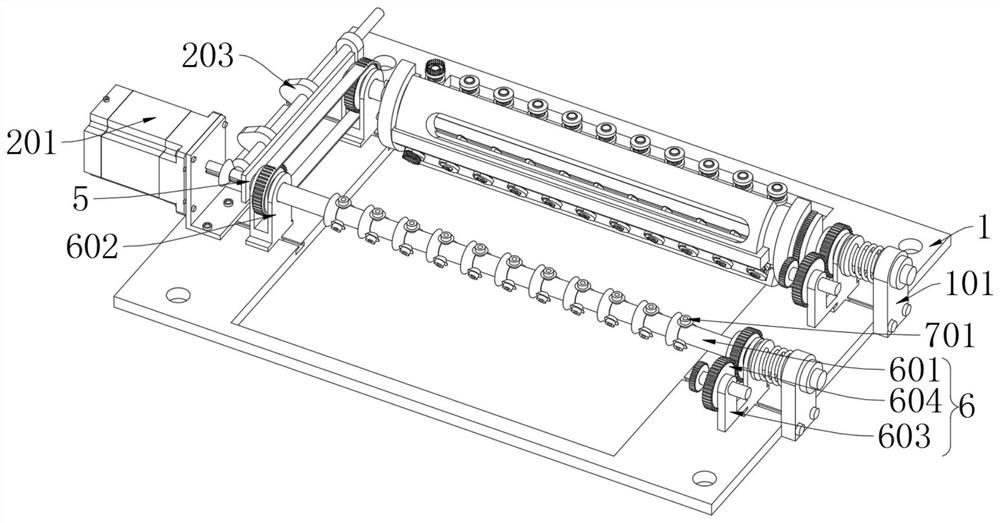

[0041] as attached figure 1 to attach Figure 13 Shown:

[0042] The present invention provides a textile dust circumventing device for textile fabric processing, which includes a base 1; a fixedly connected power mechanism 2 is installed on the base 1, and installation holes are opened on the four corners of the base 1; the base 1 includes There is a support seat 101, and two T-shaped sliding grooves are symmetrically provided on the base 1, and two lug-shaped support seats 101 are symmetrically fixed on the base 1 by bolts; The sliding hole, and a return spring is installed between the support seat 101 and the rotating shaft B601, combined with figure 1 and 2 As shown, the connecting plate 5 will be pushed to move during the rotation of the power mechanism 2, so that the rolling mechanism can slide in the sliding groove of the base 1 through the rotation mechanism 6, so that the dust removal mechanism 7 can slide and remove dust; the power mechanism 2 includes a servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com