Chemical sewage solid-liquid separator

A technology of solid-liquid separator and chemical sewage, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of troublesome cleaning and laborious cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

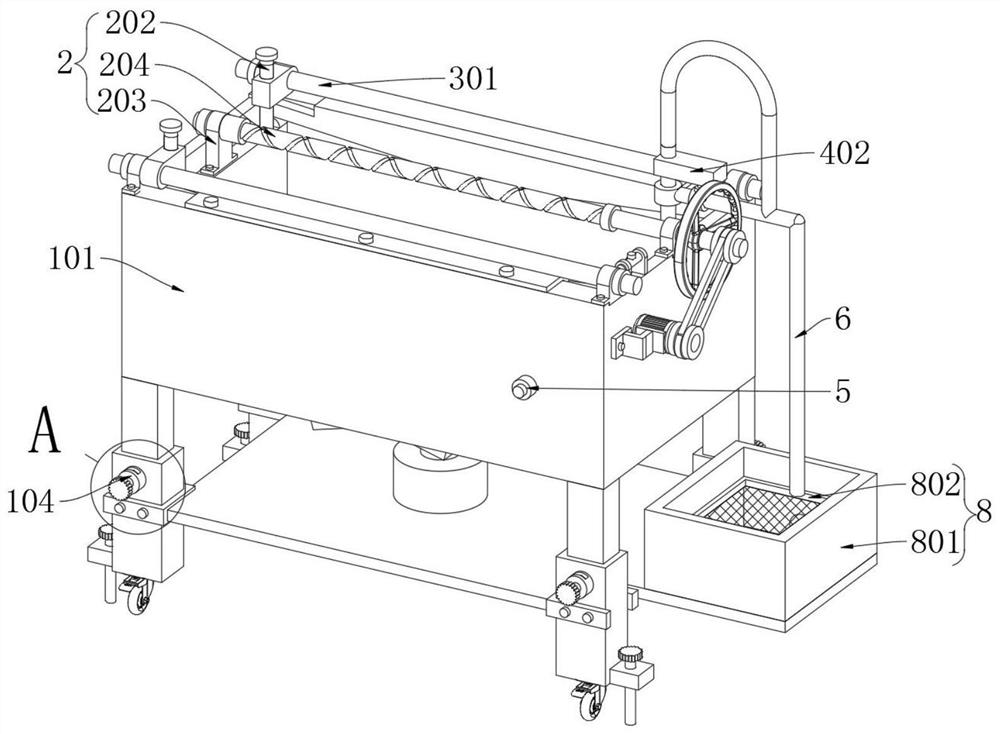

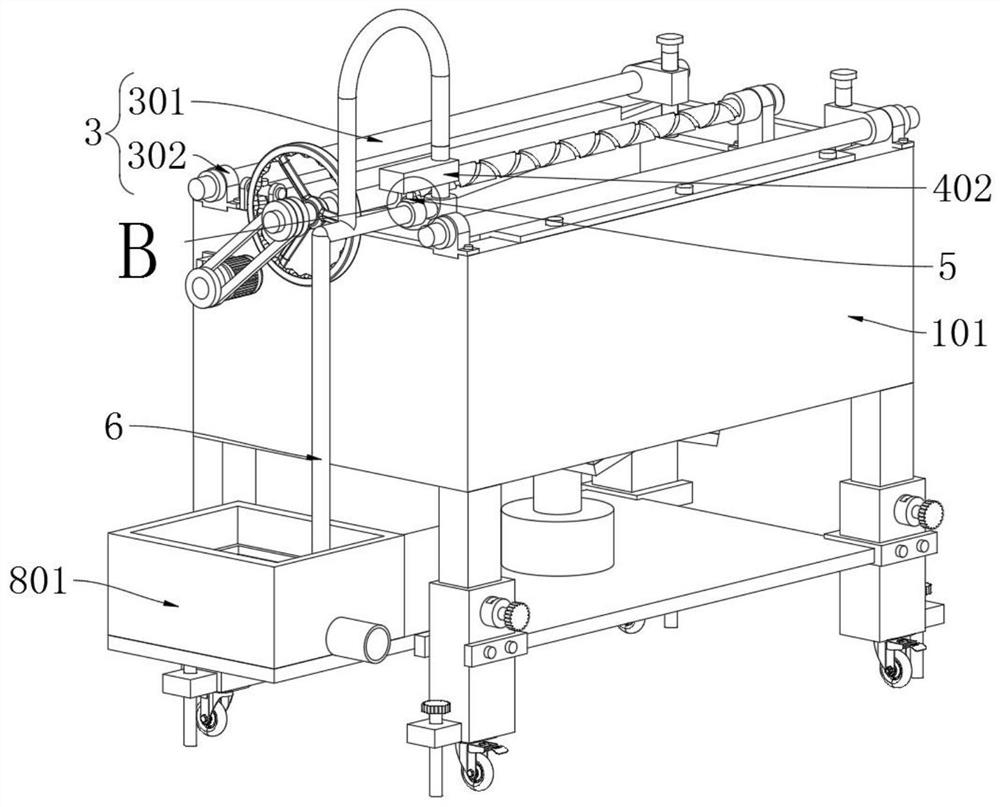

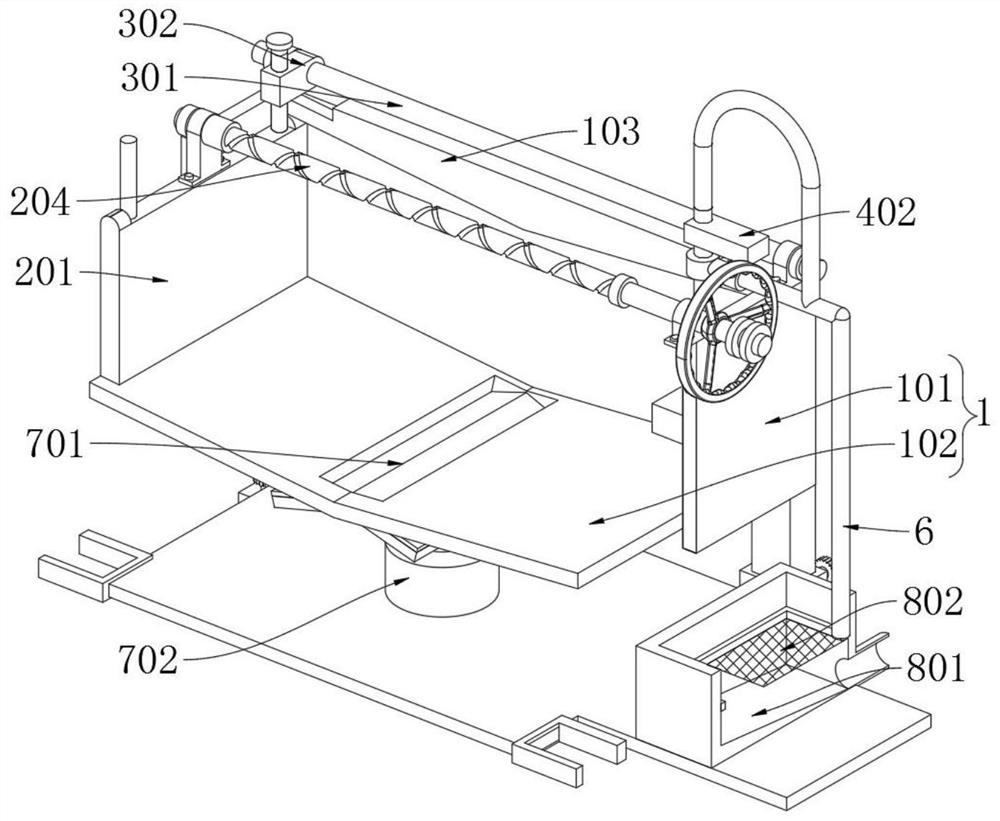

[0040] as attached figure 1 to attach Figure 10 Shown:

[0041] The present invention provides a solid-liquid separator for chemical sewage, which includes a sedimentation mechanism 1; a slidingly connected scraping mechanism 2 is installed on the sedimentation mechanism 1, and a limit nut is installed on the scraping mechanism 2; the sedimentation mechanism 1 includes a sedimentation box 101 , base plate 102, extruding block A103 and nut placement seat 104, a V-shaped base plate 102 is installed on the bottom of the settling tank 101, and a rectangular hole is provided on the base plate 102, and the inside of the settling tank 101 is provided with two extrusion The V-shaped groove that fits the block A103, and the support column at the bottom of the settling tank 101 is equipped with a nut placement seat 104. When in use, the V-shaped groove on the settling tank 101 facilitates the installation of the extrusion block A103, and also increases the extrusion pressure. With th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com