Overflow valve for isolating air

A technology of isolating air and overflow valve, which is applied in the field of sanitary ware, can solve the problems of reducing the drainage speed, etc., and achieve the effect of reducing the contact area, isolating air and overflow, and moving up and down smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

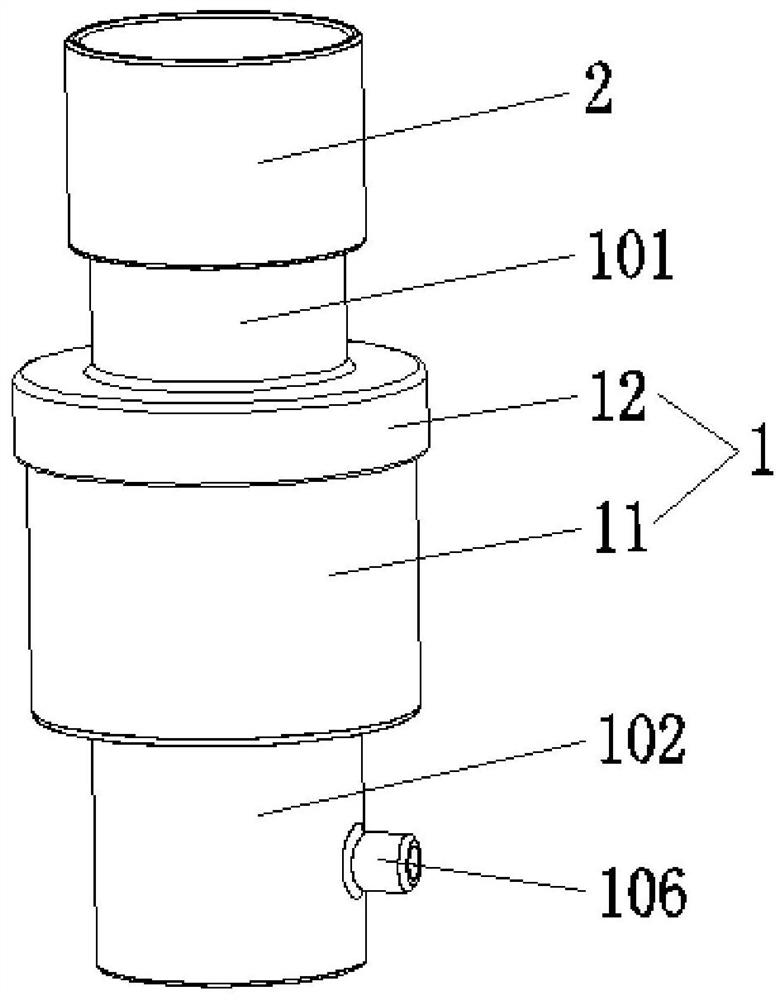

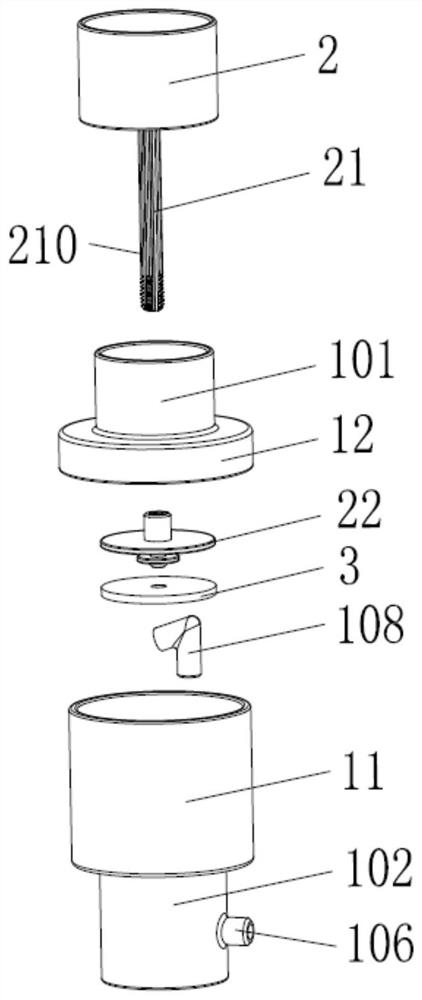

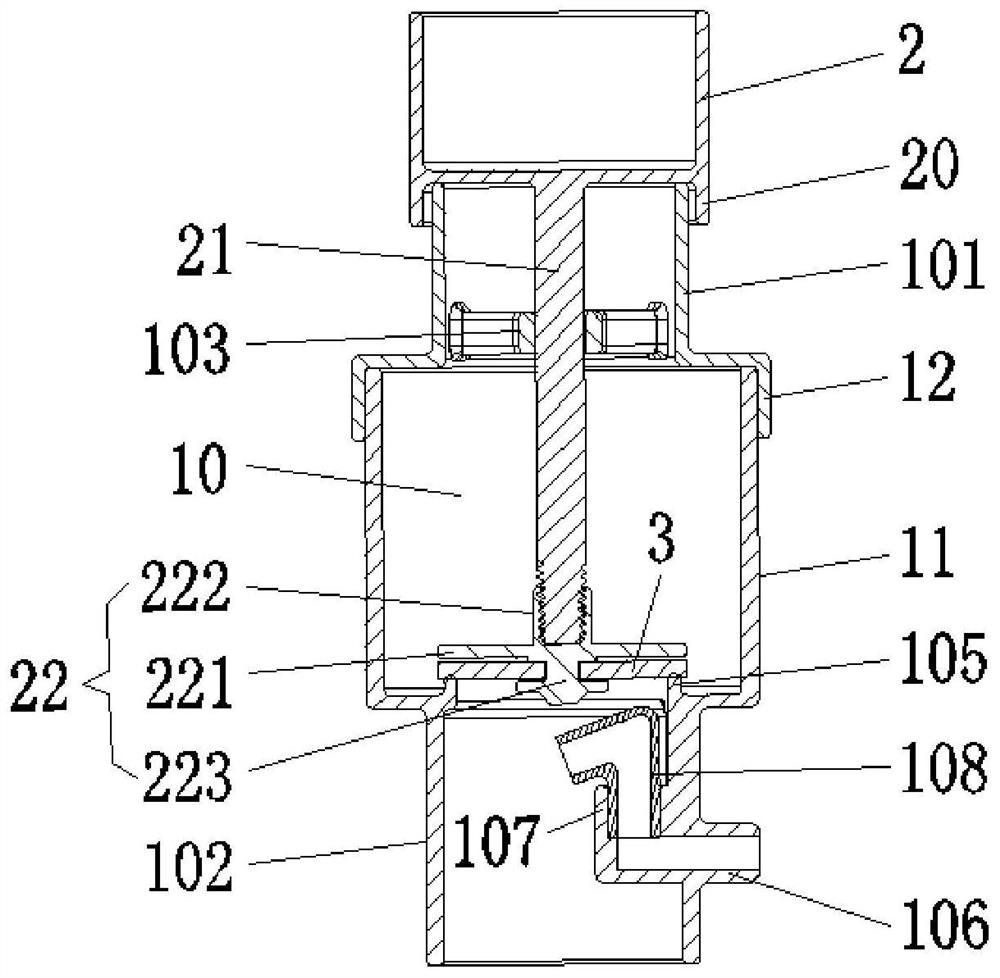

[0037] Such as Figure 1-6 As shown, an air-isolated overflow valve includes an overflow body 1 , a buoy 2 and a seal 3 . A cavity 10 is opened inside the overflow body 1 , and a water inlet pipe 101 and a drain pipe 102 communicating with the cavity 10 are respectively fixed on the top and bottom of the overflow body 1 . Preferably, the overflow body 1 includes an overflow base 11 and an overflow upper cover 12 buckled on the overflow base 11, the drain pipe 102 and the overflow base 11 are integrally formed, the water inlet pipe 101 and the overflow upper cover 12 Integral molding structure.

[0038] The buoy 2 is arranged above the overflow body 1 , the top of the buoy 2 is open, and the bottom extends downward to form a ring-shaped isolation plate 20 for being sleeved on the outside of the top of the water inlet pipe 101 .

[0039] A guide post 21 is fixed at the bottom of the buoy 2 , preferably, a plurality of guide ribs 210 are provided along the length direction on t...

Embodiment 2

[0047] Such as Figure 12-14 As shown, the difference between the present embodiment and the first embodiment is only that the side wall of the drain pipe 102 is not provided with a guide pipe 106, and the inside of the drain pipe 102 is not provided with a water storage branch pipe 107 and a water supply elbow joint 108. The rest of the structures and principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com