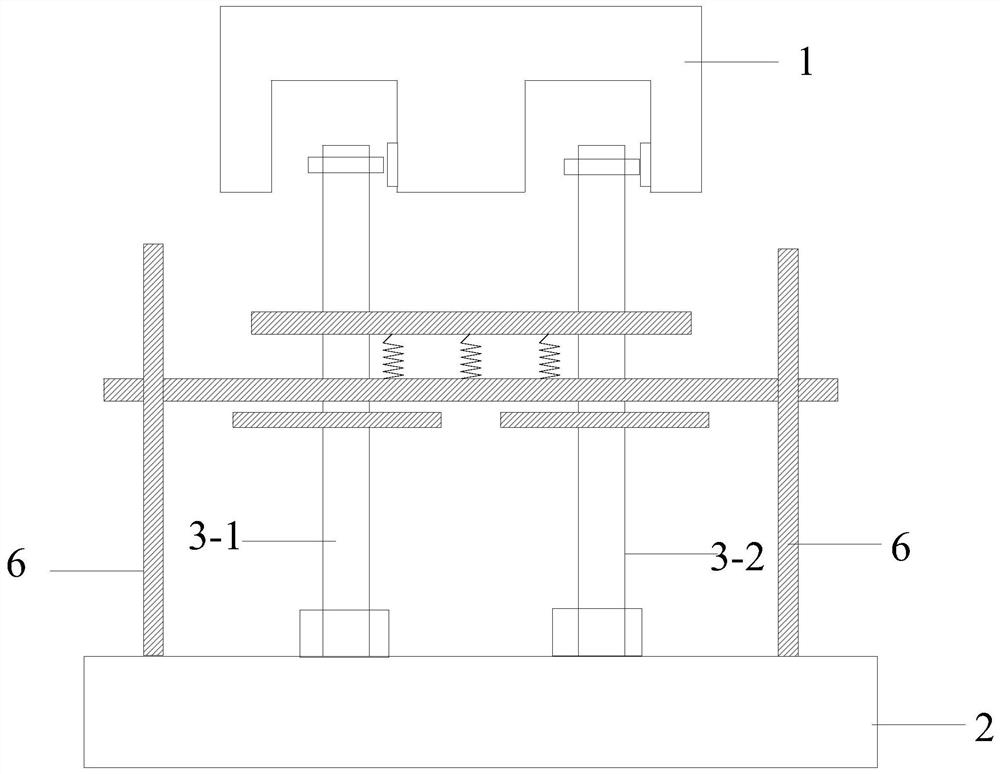

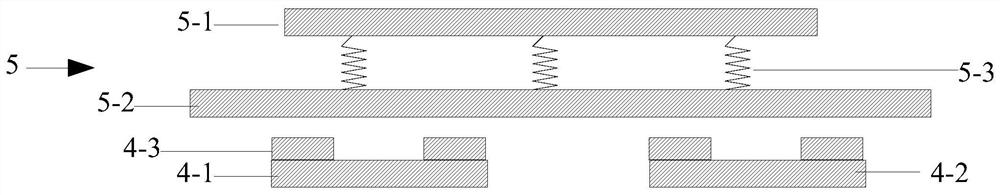

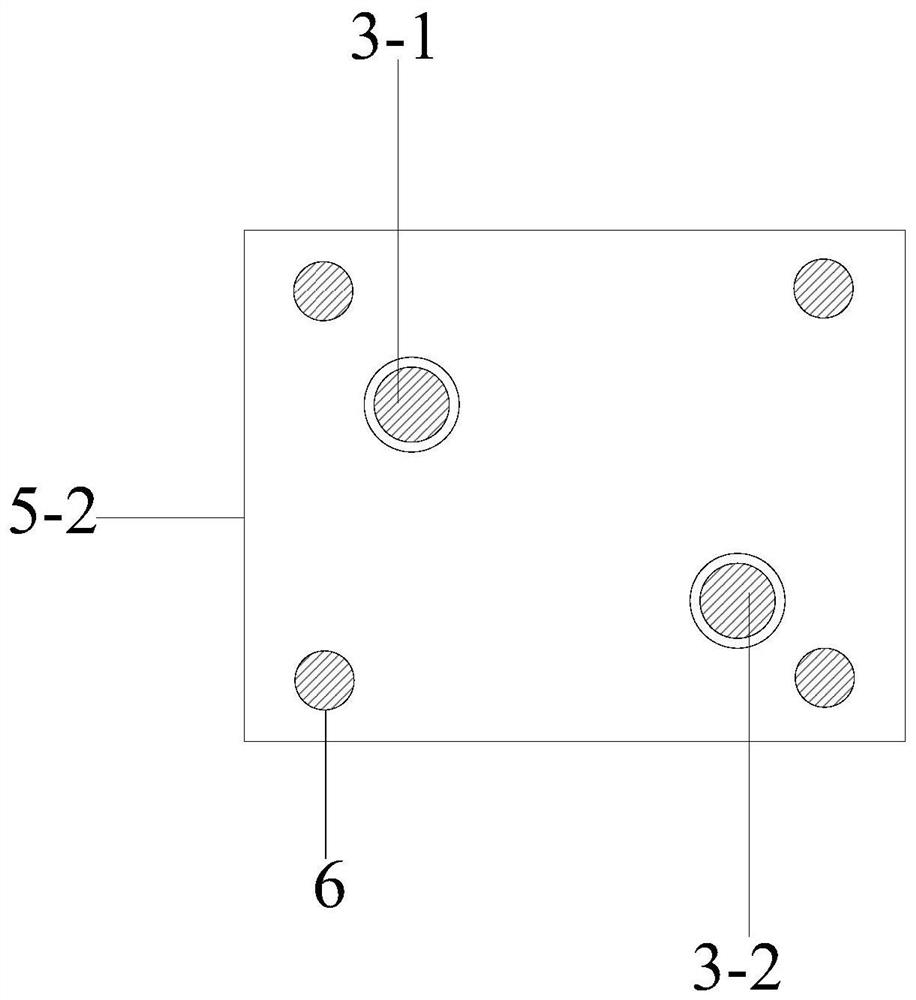

Variable-damping friction type damper, working method and prefabricated building

A friction damper technology, applied in variable damping friction dampers, prefabricated buildings, and working methods, can solve problems such as unrecoverable and easily damaged, and achieve the effect of improving damping effect and reducing damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The method of Embodiment 1 is: when the first structure and the second structure are from the equilibrium position to any point far away, only one group of damping units is active, and the pressure between the friction plate and the rotating friction energy dissipation disk is gradually Increase to increase the damping effect.

[0075] When the first structure and the second structure return to the equilibrium position from any far away point, only one set of damping units is active, and the pressure between the friction plate and the rotating friction energy dissipation disc is gradually reduced to reduce damping Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com