Rotor profile of double-toothed rotor compressor, double-toothed rotor and compressor

A technology of rotor compressor and rotor profile, which is applied in the direction of machines/engines, rotary piston machinery, mechanical equipment, etc. It can solve the problems of large exhaust resistance of compressors, many profile parameters, and thermal efficiency drop, and achieve curve formation Simple, reduced internal leakage, large exhaust flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

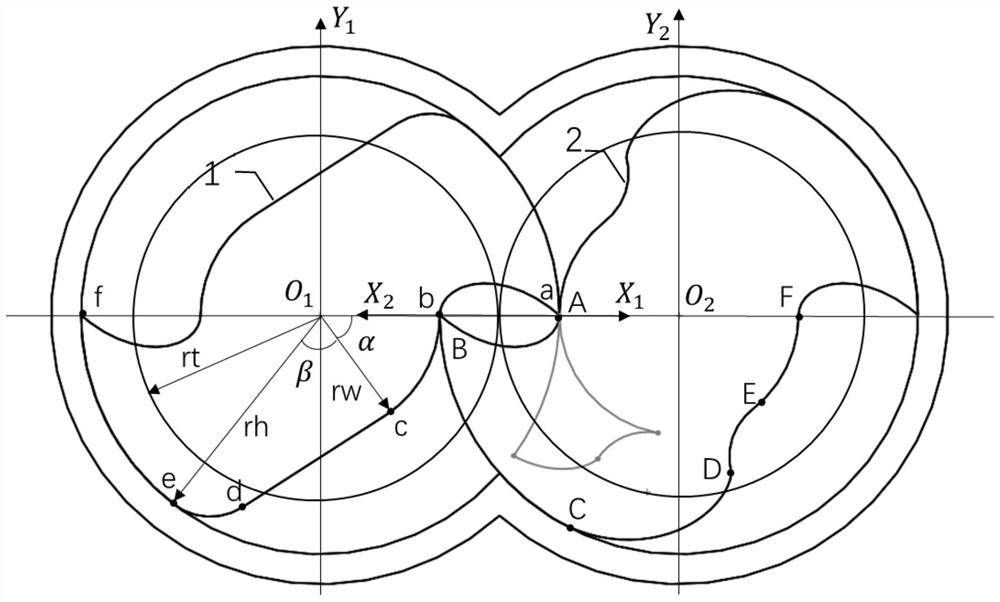

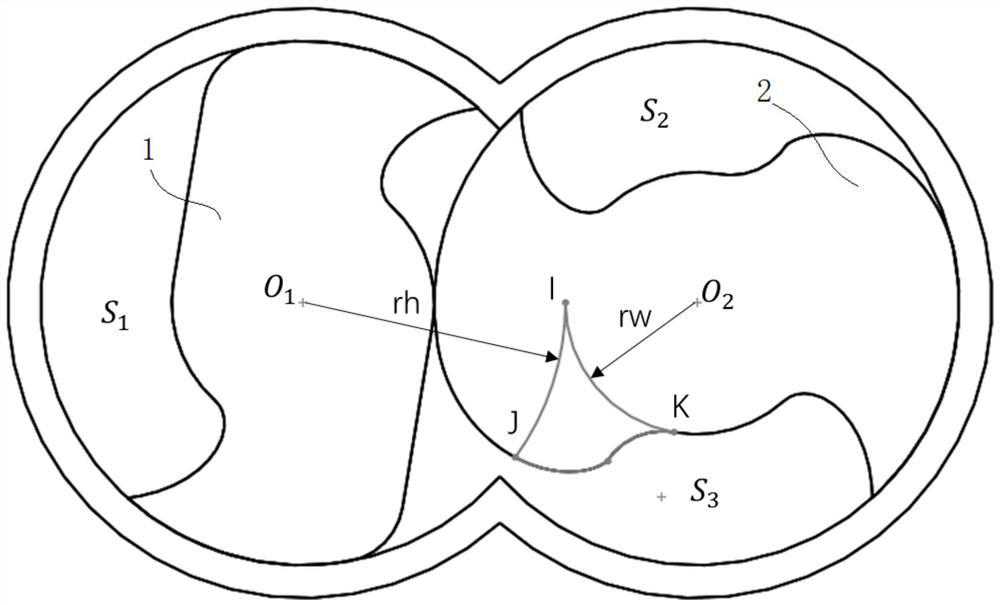

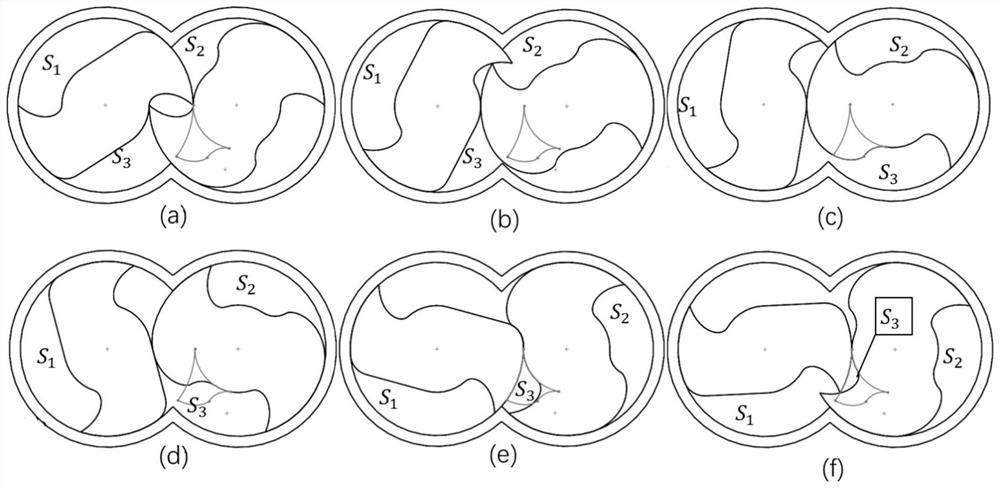

[0046] Such as figure 1 Shown is the rotor profile diagram of the double-tooth rotor compressor involved in the present invention. The rotor profile includes the profile line of the female rotor and the profile line of the male rotor. Both the female rotor 1 and the male rotor 2 are centrosymmetric structures, and the symmetrical centers are respectively for O 1 and O 2; The female rotor and the male rotor are always meshed, the female rotor and the male rotor have the same number of teeth, the profile line of the female rotor and the male rotor profile are obtained by their respective basic meshing curves through the centrosymmetric array; the basic meshing curve of the female rotor profile Including cycloid ab, tooth bottom arc bc, line segment cd, pin tooth arc de and addendum arc ef connected in sequence; the basic meshing curve of the male rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com