A Quick Response Type Self-excited Magnetic Control Reactor

A magnetically controlled reactor, fast response technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor core, reactive power compensation, etc., can solve the problem of investment cost and increase of floor area, circuit structure and Complicated control strategies and increasing the difficulty of on-site process control, etc., to achieve the effect of improving utilization, realizing rapid response, and easy integrated design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

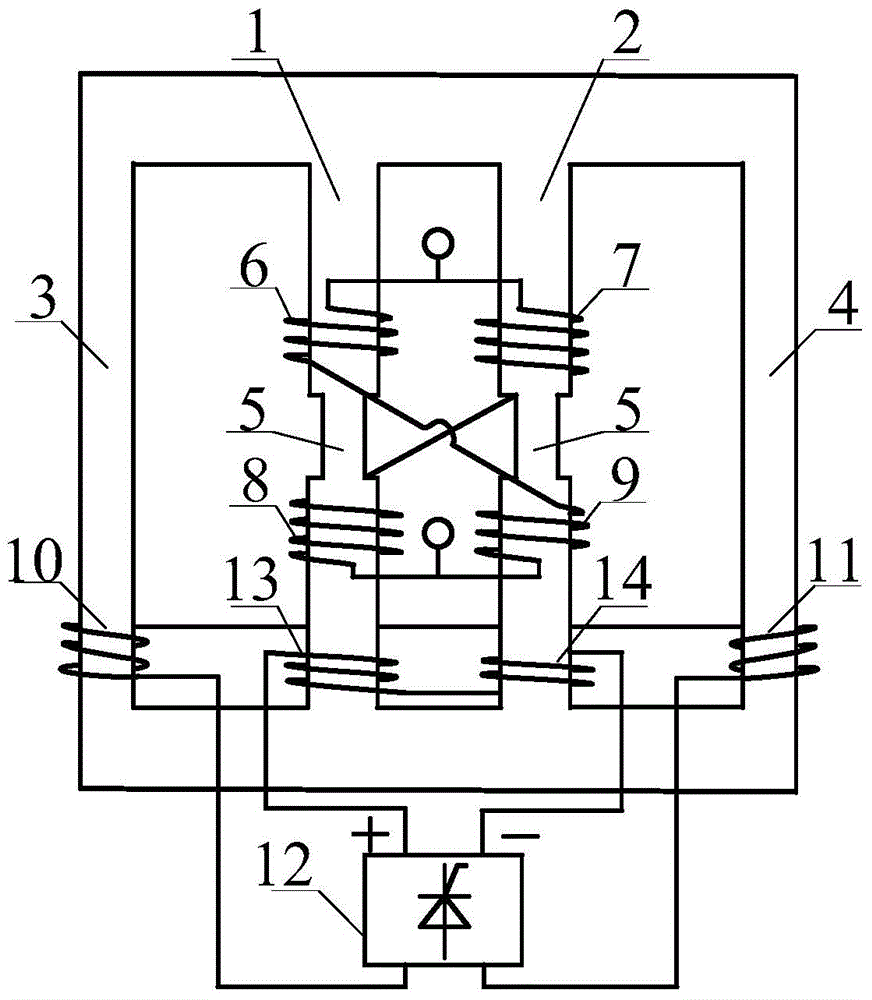

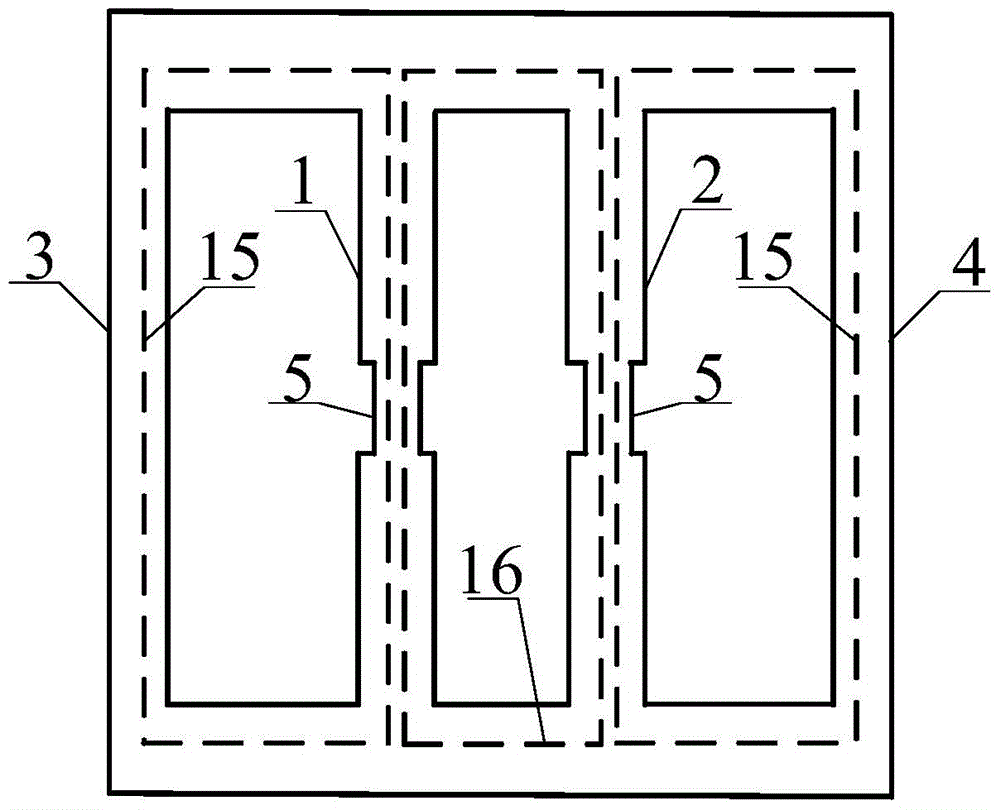

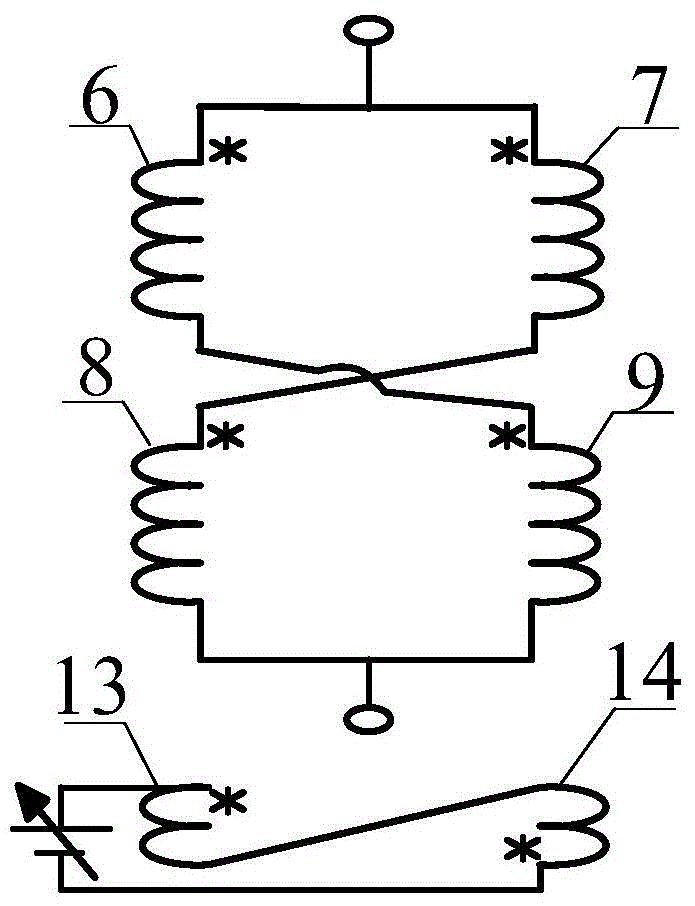

[0018] Such as Figures 1 to 3 As shown, the fast-response type self-excited magnetron reactor is characterized in that it includes a first iron core 1 and a second iron core 2, and the first iron core 1 is provided with a first working winding 6 and a fourth The working winding 9, the second working winding 7 and the third working winding 8 are arranged on the second iron core 2, the magnetic valve 5 is arranged between the first iron core 1 and the second iron core 2, and the first iron core 1 is correspondingly arranged on the side of the first iron core 1. On one side yoke 3, a first excitation winding 10 is arranged on the first side yoke 3, and a second side yoke 4 is arranged correspondingly on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com