The shape and position detection system of the selector and shift ball head of the transmission selector and shift mechanism and the shift finger

A detection system, gear selection technology, applied in the direction of mechanical measuring devices, instruments, measuring devices, etc., can solve the problems of slow detection speed, damaged synchronizer, and inability to make comprehensive judgments, and achieve optimized parameter design, convenient installation and debugging, and reliable Strong maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

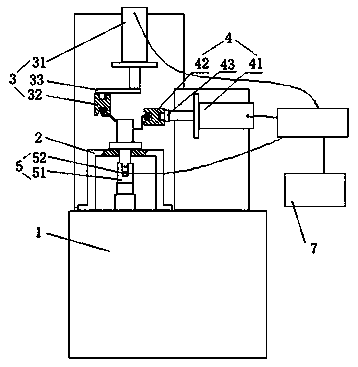

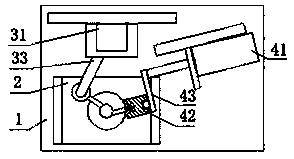

[0023] During specific implementation: if figure 1 with figure 2 As shown, a shape and position detection system of a gear selection ball head and a shift finger of a transmission selection and shift mechanism includes a base 1, and the base 1 is provided with a mounting bracket 2 for fixedly installing the gear selection mechanism to be detected. , and the selector ball detection mechanism 3 for detecting the selector ball position, the shift ball detection mechanism 4 for detecting the shift ball position and the shift finger for detecting the shift finger position Testing agency 5;

[0024] The gear selection ball head detection mechanism 3 includes a first telescopic device 31 arranged on the base 1 toward the direction of the gear selection ball head of the gear selection mechanism to be detected, and the telescopic end of the first telescopic device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com