Transformer dry casing defect simulation and performance state monitoring system and method

A condition monitoring system and dry bushing technology, which is applied in the direction of dielectric property measurement, machine/structural component testing, optical method testing, etc., to achieve the effects of ensuring safety, fast and accurate monitoring, and ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

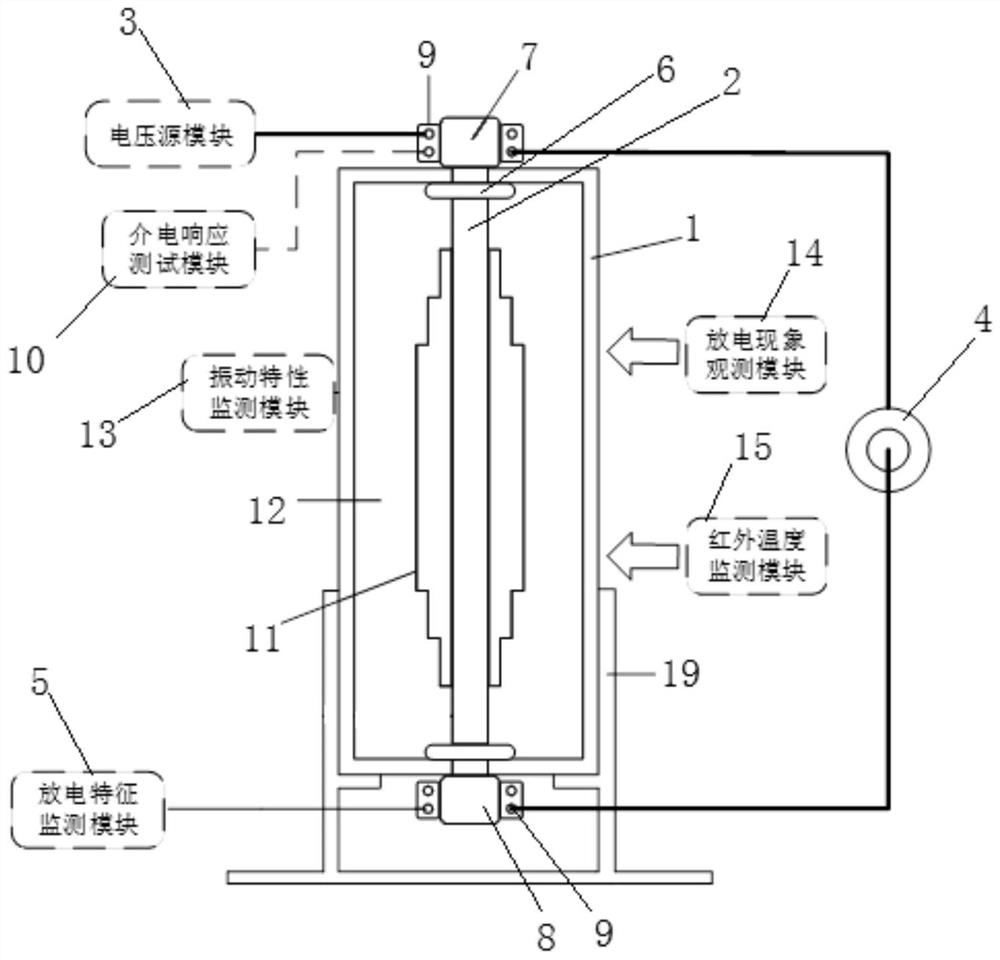

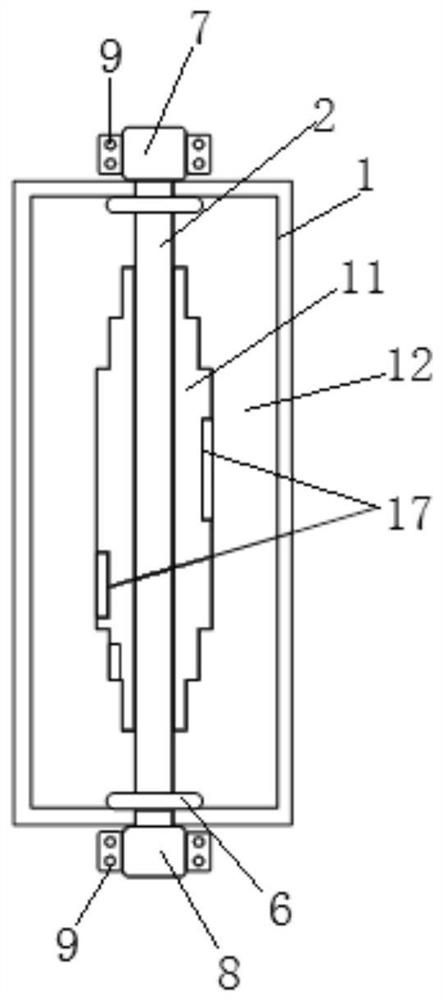

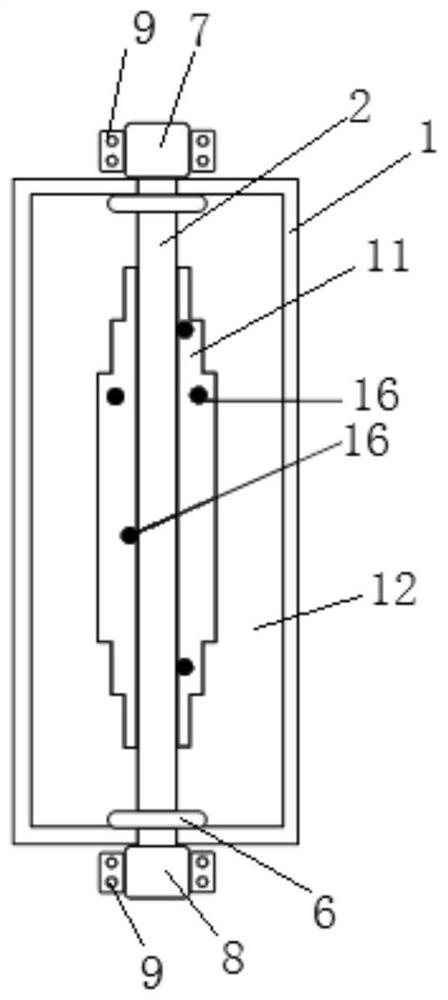

[0019] The transformer dry-type bushing defect simulation and performance state monitoring system designed by the present invention, such as figure 1 As shown, it includes a transparent plexiglass cavity 1, a conductive rod 2 penetrating through the transparent plexiglass cavity 1, a voltage source module 3, a current source module 4, a discharge characteristic monitoring module 5 and a dielectric response test module 10, wherein the conductive The two ends of the rod 2 are connected with the transparent organic glass cavity 1 by a sealing ring 6, and the two ends of the conductive rod 2 protruding from the transparent organic glass cavity 1 are respectively connected with a first equalizing ring 7 and a second equalizing ring 8, One end of the conductive rod 2 is connected to the voltage source output terminal of the voltage source module 3 (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com