Simple electric welding machine secondary line and weldment lap joint device

A lapping device and secondary line technology, applied in the direction of electrical component connections, electrical components, conductive connections, etc., can solve problems such as irregular welding operations, large oil stains on the surface of welded parts, and cumbersome tasks, so as to avoid unsafe behaviors, The effect of improving welding efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

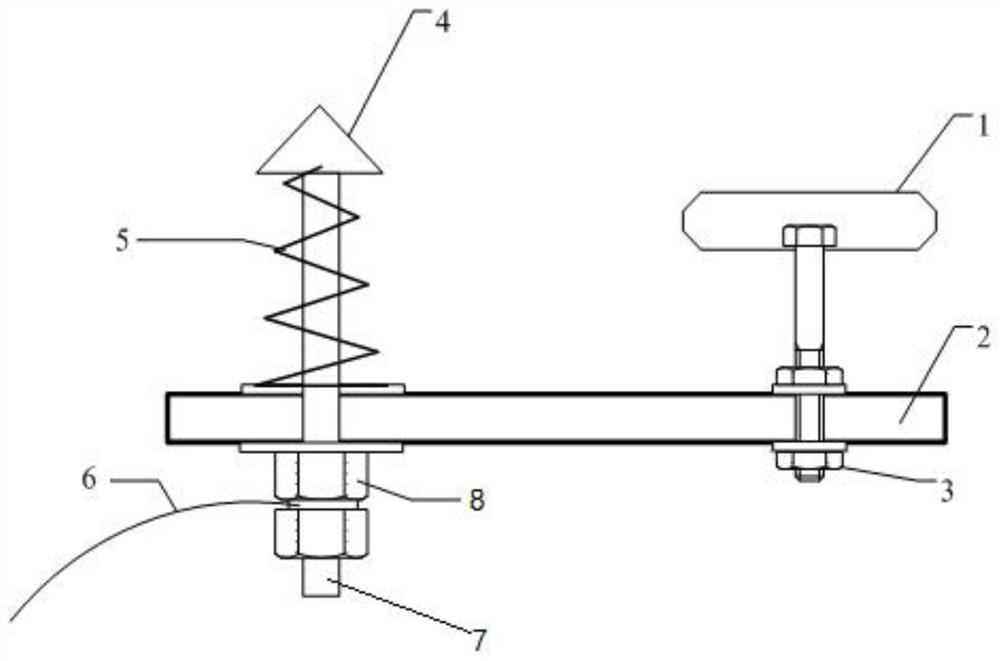

[0018] Such as figure 1 As shown, a simple welding machine secondary wire and weldment overlapping device includes a bakelite board 2, one end of the bakelite board 2 is fixedly connected with a strong magnet 1 through a first screw 3, and the other end of the bakelite board 2 A second screw rod 7 with a copper plug 4 is provided. The copper plug 4 and the strong magnet 1 are located on the same side of the bakelite 2. After the second screw 7 passes through the bakelite 2, the Two nuts 8 are threaded, and an adjustment spring 5 is set on the second screw rod 7 between the copper plug 4 and the bakelite 2. When the adjustment spring 5 is in a free state, the copper plug The distance between 4 and the bakelite board 2 is greater than the distance between the strong magnet 1 and the bakelite board 2, and the second screw 7 between the two nuts 5 is connected to the secondary wire 6 of the welding machine.

[0019] In the present embodiment, 1 piece of 10mm thick bakelite is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com