A multi-functional roll-plate laminating printing machine

A multi-functional, printing machine technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve the problems of low quality of cleaning coils, reducing film coating efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

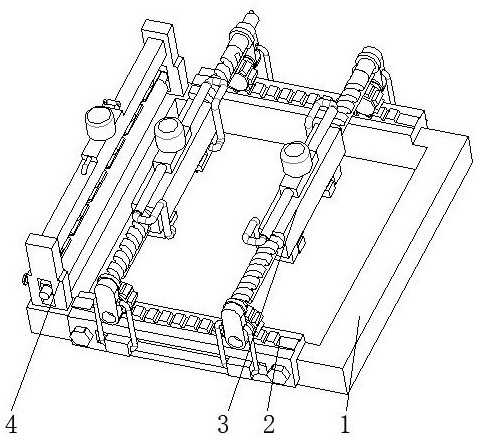

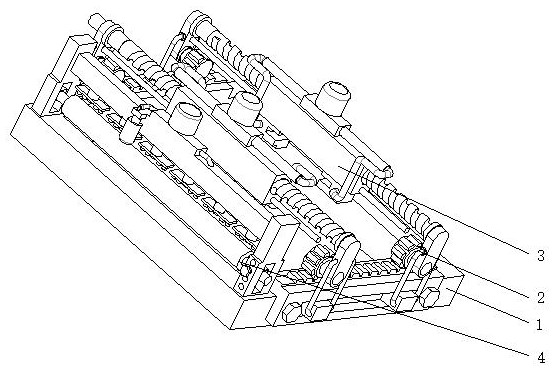

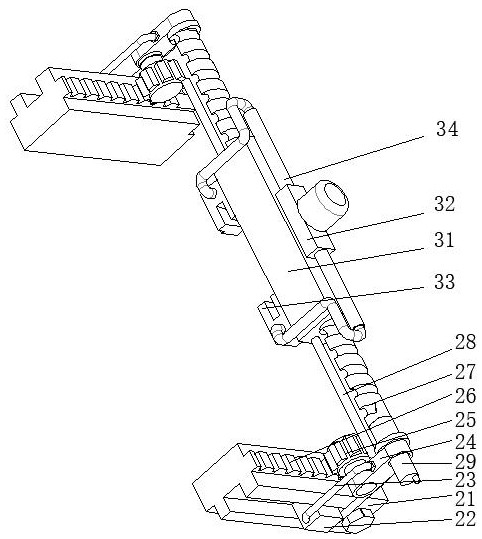

[0033] Such as figure 1 , 2 , 4, 5, 6, and 7, the embodiment of the present invention provides a multifunctional roll plate laminating printing machine, the brush structure 483 includes a sleeve 4831 and a rectangular block 4834, and the bottom of the mounting plate 481 is fixedly installed with a sleeve 4831, the inside of the casing 4831 is rotatably connected with a rotating rod 4832, the outer surface of the rotating rod 4832 located on both sides of the dust collecting cover 482 is provided with fan blades 4833 in opposite directions, and the outer surface of the rectangular block 4834 is inserted with a spring pin 4835, The top of the rectangular block 4834 is provided with a slot, the outer surface of the rotating rod 4832 is provided with a pin hole matching the size of the elastic pin 4835, the back of the rectangular block 4834 is fixedly equipped with a brush plate 4836, and the outer surface of the brush plate 4836 A hole is opened, and the fan 47 communicates wit...

Embodiment 2

[0035] Such as figure 1 , 2 , 4, 5, 6, and 7, the embodiment of the present invention provides a multifunctional roll plate laminating printing machine, the brush structure 483 includes a sleeve 4831 and a rectangular block 4834, and the bottom of the mounting plate 481 is fixedly installed with a sleeve 4831, the inside of the casing 4831 is rotatably connected with a rotating rod 4832, the outer surface of the rotating rod 4832 located on both sides of the dust collecting cover 482 is provided with fan blades 4833 in opposite directions, and the outer surface of the rectangular block 4834 is inserted with a spring pin 4835, The top of the rectangular block 4834 is provided with a slot, the outer surface of the rotating rod 4832 is provided with a pin hole matching the size of the spring pin 4835, the back of the rectangular block 4834 is fixedly equipped with a cleaning cloth, and the outer surface of the cleaning cloth is provided with holes. The fan 47 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com