Aircraft with double-fuselage tandem wing vertical take-off and landing layout

A technology of vertical take-off and landing and tandem wings, which is applied in the field of aviation aircraft and can solve the problems that aircraft cannot take off and land stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

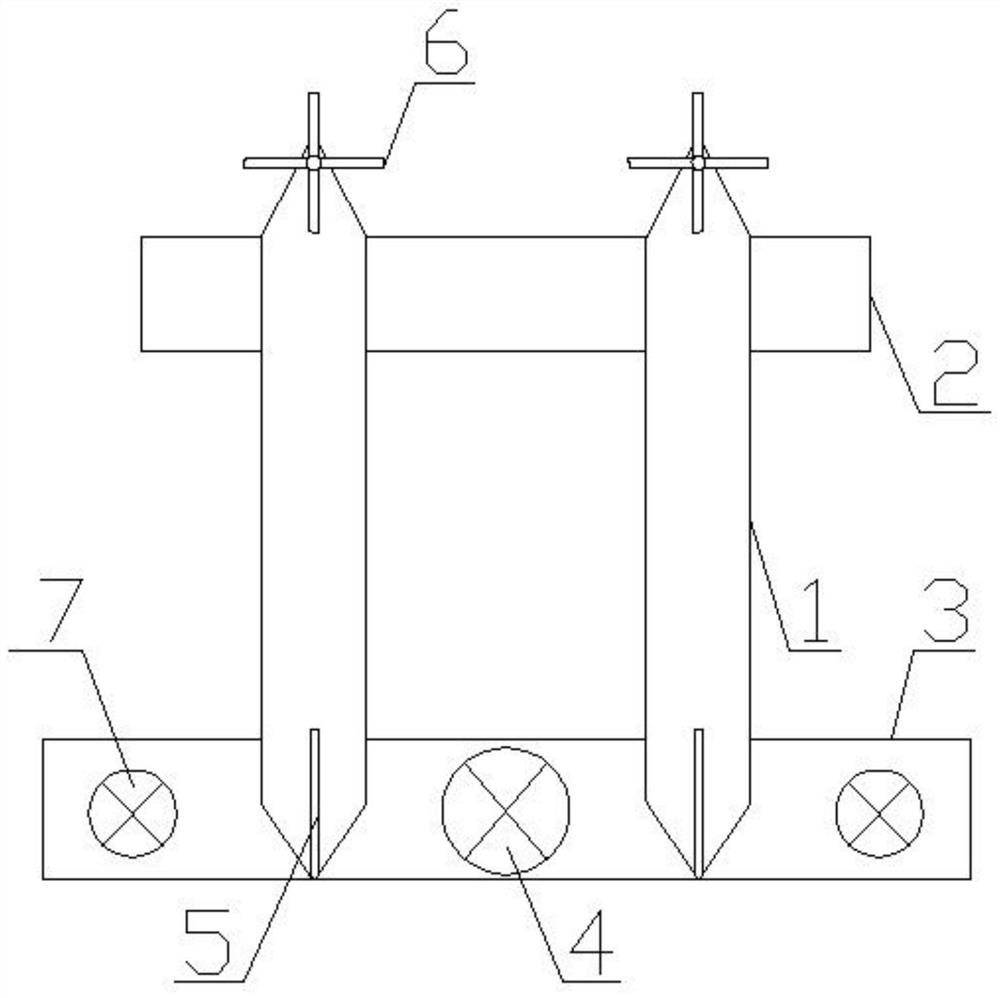

[0023] as attached figure 1 Shown: an aircraft with twin-fuselage tandem-wing vertical take-off and landing layout, including two fuselages 1 arranged at intervals. The use of twin-fuselage 1 can increase the load space of the whole aircraft and facilitate the loading of large-sized cargo or equipment. An engine is installed on the fuselage 1, and a front tandem wing 2 and a rear tandem wing 3 are welded at common intervals on the two fuselages 1, and the length of the front tandem wing 2 is shorter than that of the rear tandem wing 3, the rear tandem wing 3 is equipped with the first lift fan 4 between the two fuselages 1 and the slipstream rudder located below the first lift fan 4, and the first lift fan 4 is electrically connected to the engine , the first lift fan 4 adopts a closed lift fan, directly driven by the engine, with high hovering efficiency, heavy take-off weight, and large cargo load; heading control with the aid of slipstream rudders, high efficiency, large st...

Embodiment 2

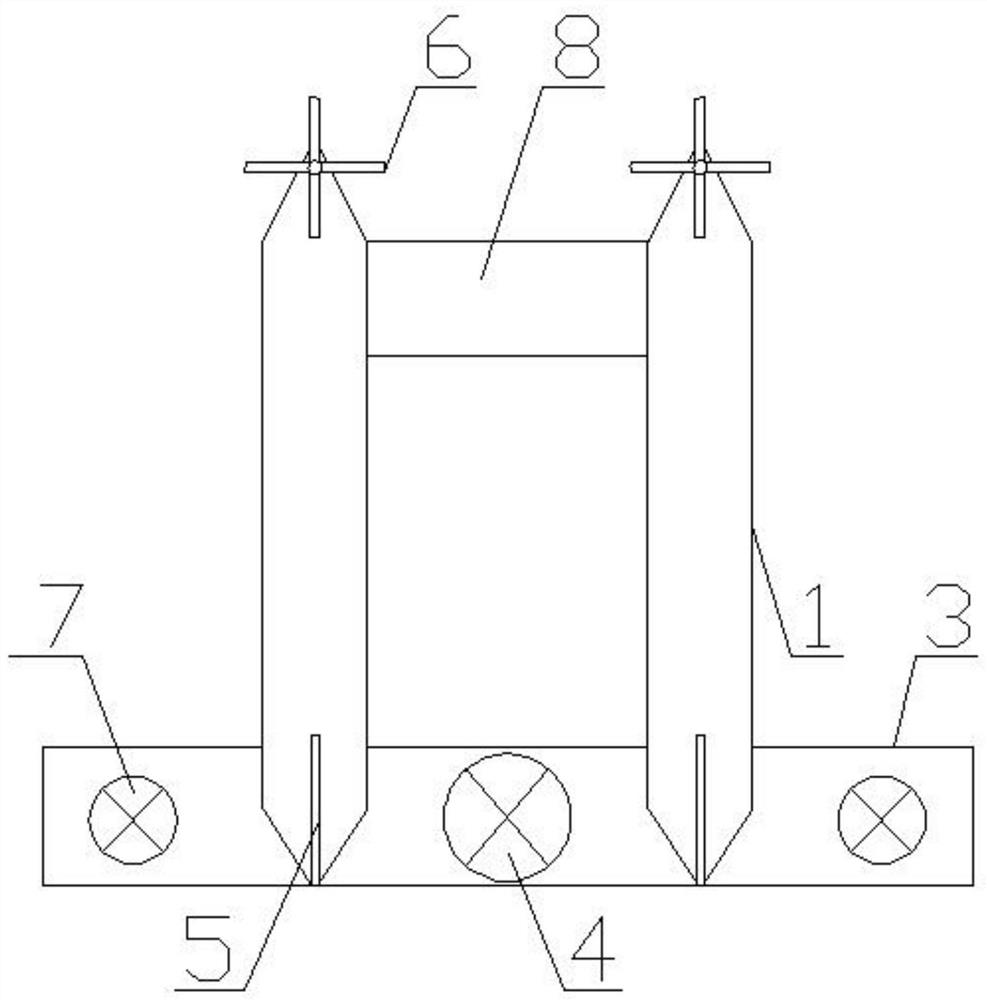

[0028] as attached figure 2 As shown, the difference between the present embodiment and embodiment 1 is only that the front tandem wing 2 is a canard 8. In this embodiment, the aircraft can generate trim and pitch control moments by means of the canard 8, which can better trim the aircraft.

Embodiment 3

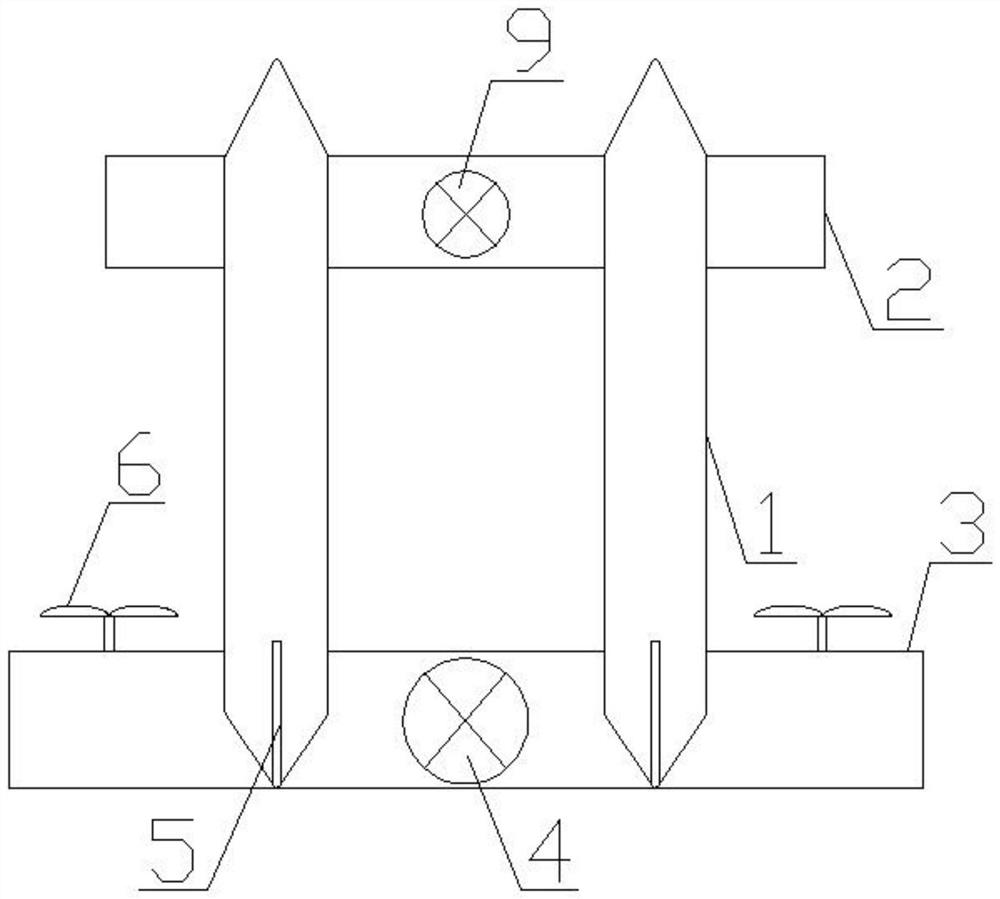

[0030] as attached image 3 As shown, an aircraft with a vertical take-off and landing layout with twin fuselages and tandem wings includes two fuselages 1 arranged at intervals. The use of twin fuselages 1 can increase the load space of the whole aircraft and facilitate the loading of large-sized cargo or equipment. An engine is installed on the fuselage 1, and a front tandem wing 2 and a rear tandem wing 3 are welded at common intervals on the two fuselages 1, and the length of the front tandem wing 2 is shorter than that of the rear tandem wing 3, the front tandem wing 2 is equipped with a second lift fan 9 between the two fuselages 1, the second lift fan 9 is electrically connected to the engine, and the front tandem wing 2 is opened for The duct of the second lift fan 9 is installed. The first lift fan 4 positioned between the two fuselages 1 and the slipstream rudder positioned below the first lift fan 4 are installed on the rear tandem wing 3, the first lift fan 4 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com