Medical garbage can

A technology of trash cans and barrels, applied in trash cans, garbage collection, household appliances, etc., can solve problems such as increasing the infection risk of medical staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

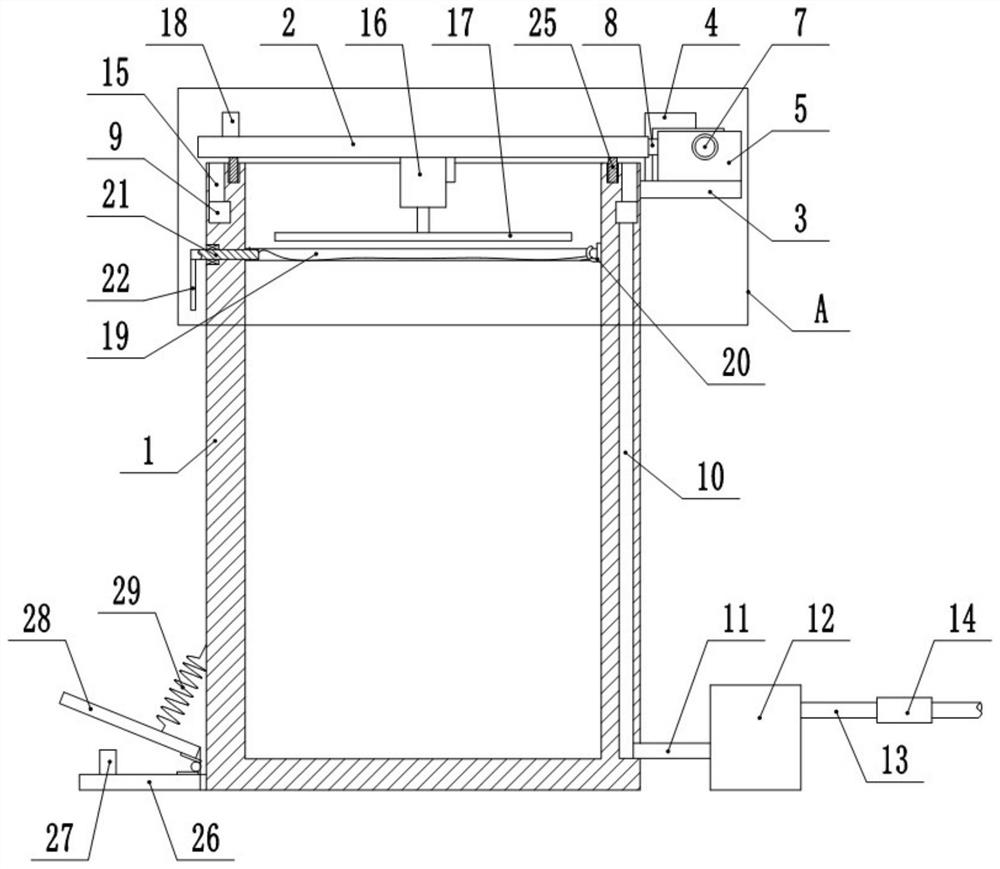

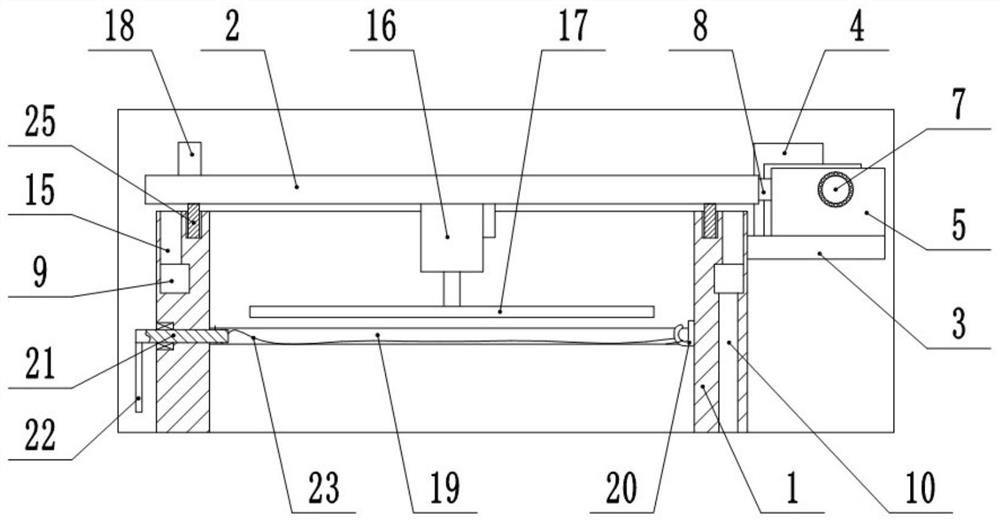

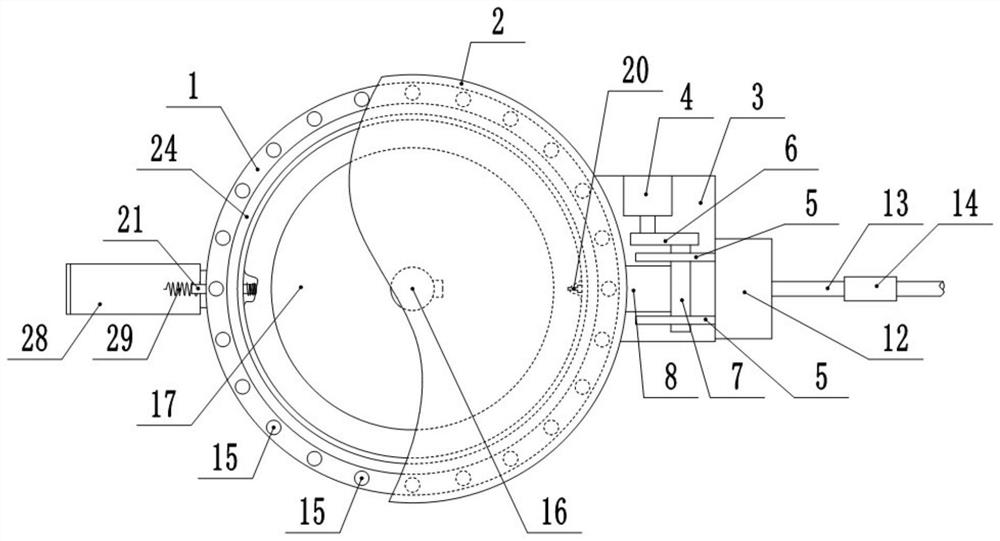

[0033] This embodiment is basically as figure 1 and figure 2 Shown: a kind of medical waste bin, comprises bucket body 1 and bucket lid 2, and the top of bucket body 1 is fixedly installed with the mounting plate 3 that horizontally arranges, and combines image 3 As shown, the mounting plate 3 is fixedly installed with a drive motor 4 and two opposite vertical plates 5, the output end of the drive motor 4 is connected to a rotating shaft 7 through a reducer 6, and the rotating shaft 7 is connected in rotation with the vertical plate 5 through a bearing; The right end of 2 is welded with connecting plate 8, and the right end of connecting plate 8 is welded with rotating shaft 7. In this embodiment, the drive motor 4 is a forward and reverse motor, and the drive motor 4 rotates clockwise for a period of time (about 7s), then stops for a period of time (about 10s), and then rotates counterclockwise for a period of time (about 7s), thereby leaving Go out sufficient time so tha...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, the right end of the rotating roller 21 is provided with an annular groove 30 , and the two free ends of the twisted rope 23 are all knotted in the annular groove 30 of the rotating roller 21 . In this embodiment, the annular groove 30 is used to limit the twisted rope 23 after knotting, so as to prevent the twisted rope 23 from detaching from the rotating roller 21 during the twisting process, thereby ensuring that the twisted rope 23 can successfully seal the garbage bag.

Embodiment 3

[0048] The difference between this embodiment and embodiment one or two is; Figure 5 As shown, the filter 14 is not installed in the exhaust pipe 13, but the exhaust pipe 13 is connected with a liquid storage chamber 31, and a sponge strip 32 is placed in the liquid storage chamber 31, and the sponge strip 32 extends into the exhaust pipe 13 And the sponge strip 32 is filled with the exhaust pipe 13, and the liquid storage cavity 31 is filled with 75% alcohol solution. The top of the liquid storage chamber 31 is communicated with a liquid replenishment tube 33 , and the end of the liquid replenishment tube 33 is screwed with a screw cap 34 .

[0049] In this embodiment, a section of the exhaust pipe 13 is filled with a sponge strip 32, and after the sponge strip 32 absorbs the 75% alcohol solution in the liquid storage chamber 31, when the air in the exhaust pipe 13 passes through the sponge strip 32, 75% The alcohol solution kills viruses in the air, so the sanitized air ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com