Flat knitting machines with devices for inserting inserts into knitted fabrics

A technology of embedded parts and knitted fabrics, which is applied to flat knitting machines with individual moving needles, knitting, weft knitting, etc., which can solve the problems of interrupted fabric manufacturing and increased manpower input, and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

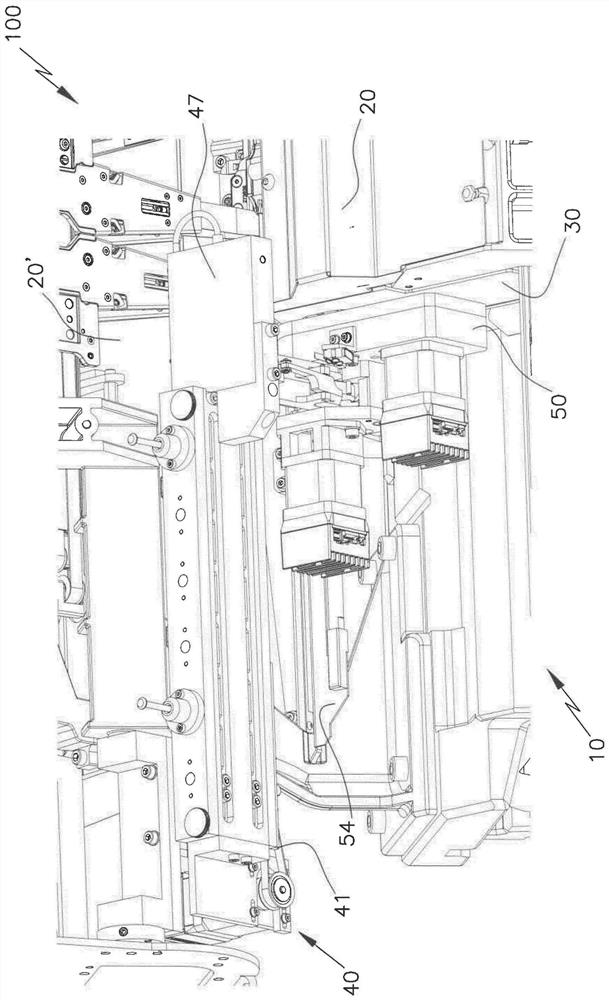

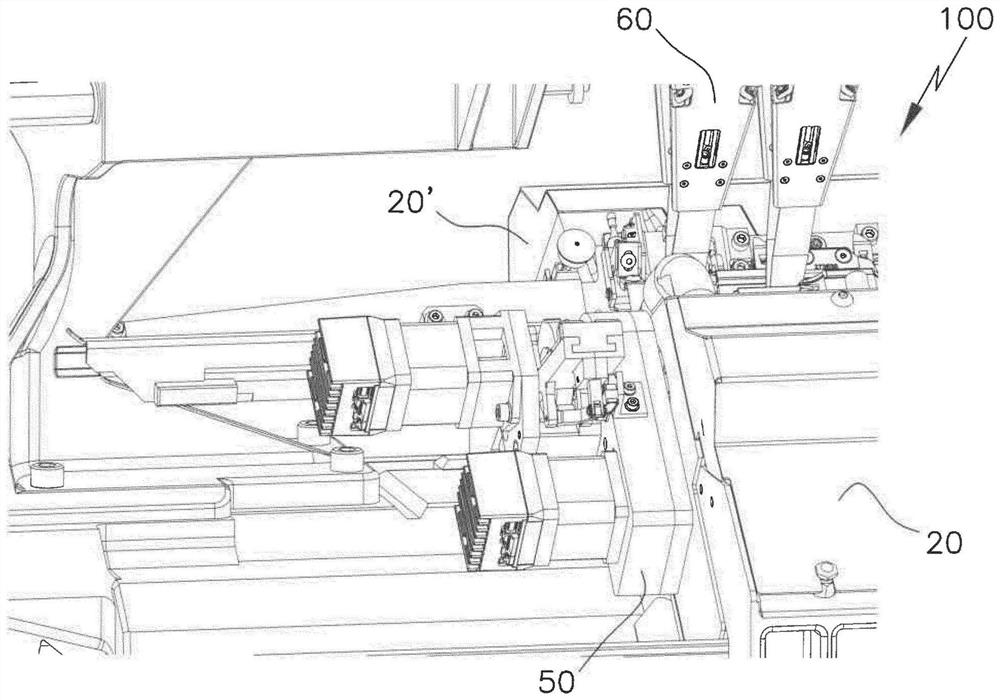

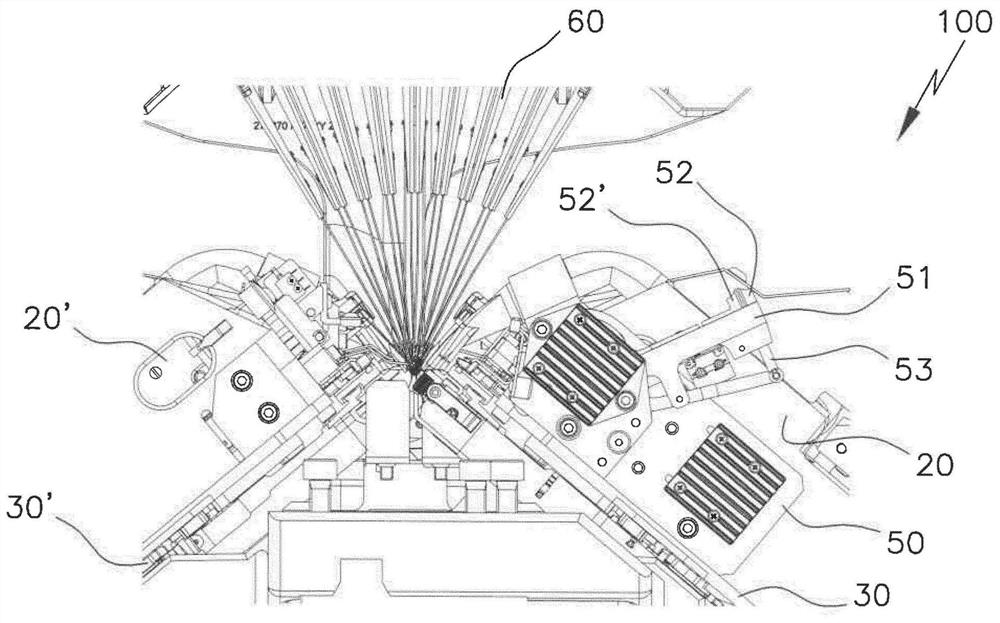

[0034] figure 1 Shown is a schematic illustration of a detail of a flat knitting machine 100 known per se, with front and rear needle beds not shown here. Front and rear carriages 20 , 20 ′ move along these needle beds, on which carriages knitting cams 30 , 30 ′ are fastened.

[0035] The flat knitting machine 100 has a function for inserting the insert 70 ( Figure 4b ) device 10 inserted into a knitted fabric produced on a flat knitting machine, consisting of a storage box 40 for an insert 70 and a gripping mechanism 50 for an insert 70, the storage box is rigidly arranged here without Shown next to the left side of the needle bed.

[0036] The magazine 40 is designed for storage and delivery of inserts 70 , which can be stored in a magazine container 41 for this purpose and, if necessary, delivered by means of a conveying mechanism not shown in detail here. In this case, the delivery device can be used to reach a defined delivery position of the insert 70 . This defined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com