Cement coating device for wall building

A cement and wall-laying technology, which is applied in construction, building structure, and building material processing, etc., can solve the problems of waste, cement easily falling to the ground, laborious and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

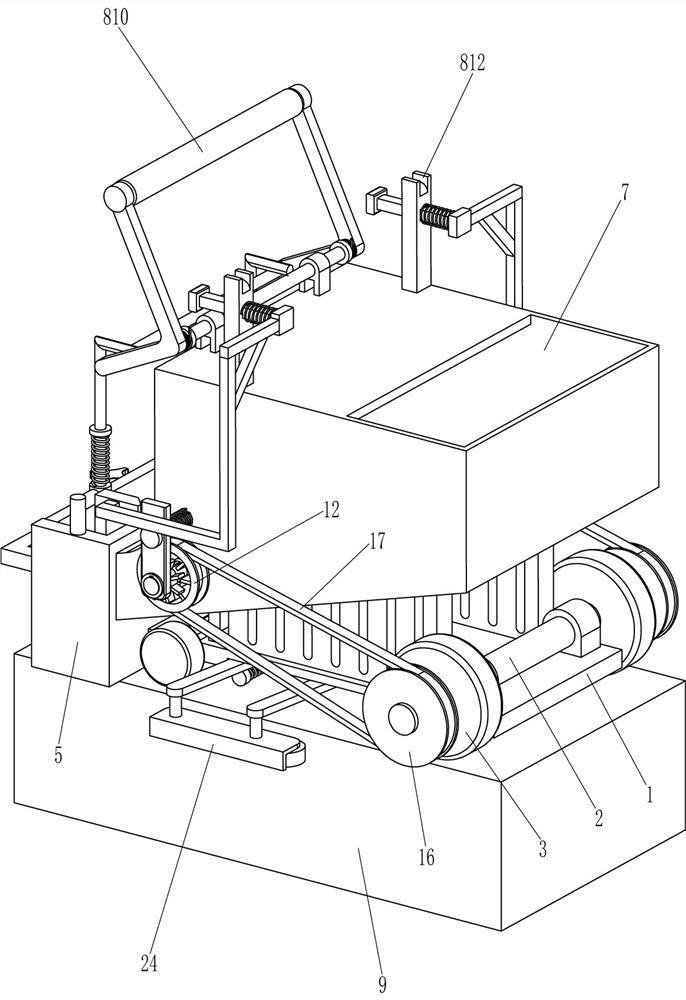

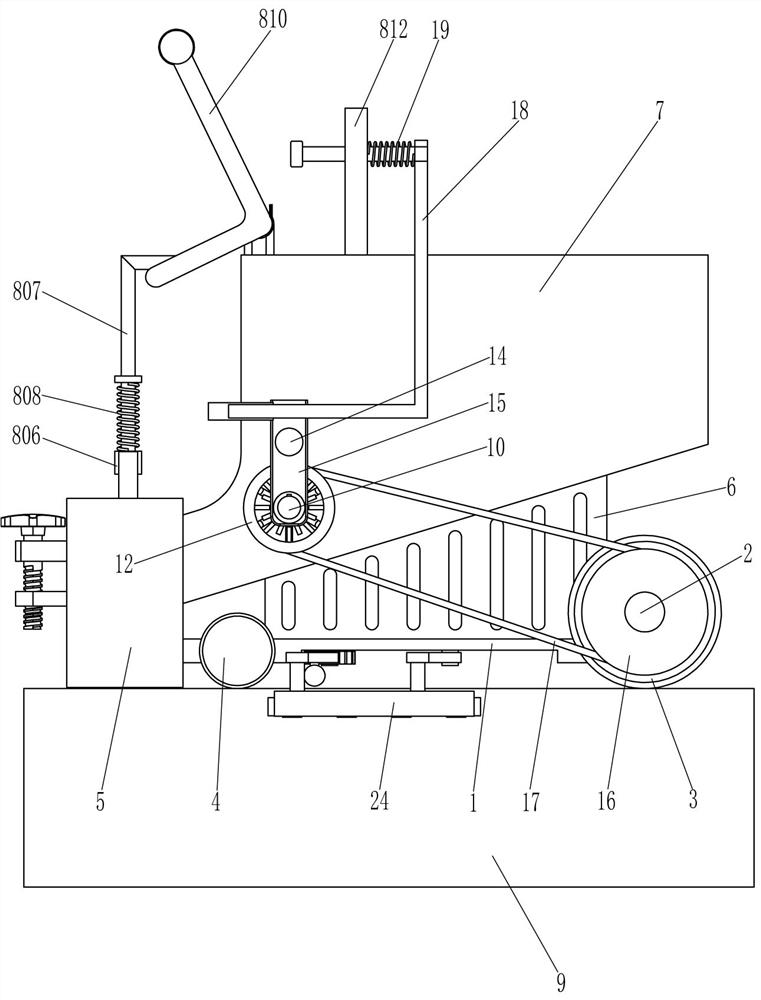

[0023] A cement smearing device for building walls, such as Figure 1-Figure 3 As shown, it includes a bottom plate 1, a first rotating shaft 2, a first roller 3, a second roller 4, a u-shaped frame 5, a support plate 6, a material storage box 7 and a smearing assembly 8, and the top right side of the bottom plate 1 is connected in a rotating manner. There is a first rotating shaft 2, the first rotating shaft 2 is fixedly connected with the first roller 3 in the circumferential direction, the left side of the front and rear sides of the bottom plate 1 is connected with the second roller 4 in a rotating manner, and the left side of the bottom plate 1 is fixed with a U-shaped frame 5, a support plate 6 is fixedly connected in the middle of the front and rear sides of the top of the bottom plate 1, and a storage box 7 is fixedly connected between the tops of the support plates 6 on the front and rear sides, and the discharge end of the storage box 7 is connected to the u-shaped fr...

Embodiment 2

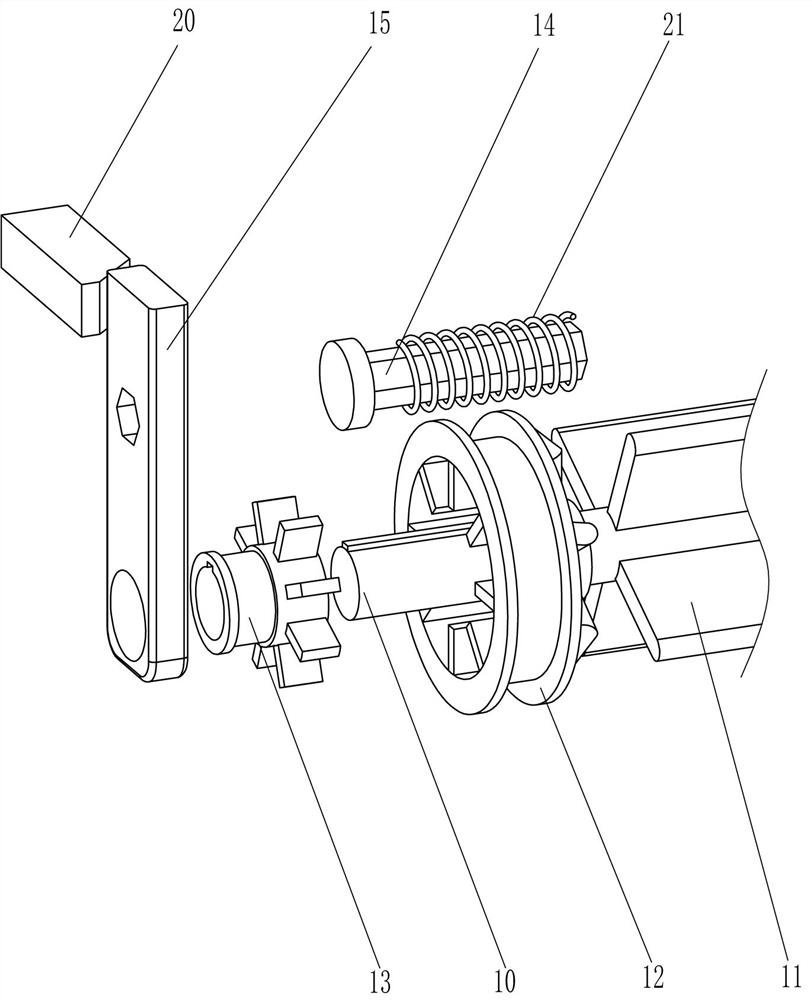

[0028] On the basis of Example 1, such as Figure 1-Figure 4 As shown, it also includes a second rotating shaft 10, a second scraper 11, a clutch drive wheel 12, a clutch sleeve 13, a hexagonal rod 14, a slider 15, a rotating drive wheel 16 and a belt 17, and the front and rear ends of the first rotating shaft 2 Both are fixedly connected with a rotating transmission wheel 16, and a second rotating shaft 10 is rotatably connected between the lower side of the left side of the front and rear sides of the storage box 7, and the two parts of the second rotating shaft 10 are rotatably connected with a clutch transmission wheel in the circumferential direction. 12. The clutch transmission wheel 12 is located outside the material storage box 7, and a belt 17 is wound between the clutch transmission wheel 12 on each side and the corresponding rotary transmission wheel 16, and the lower left side of the front and rear sides of the storage box 7 is fixed with hexagonal edges. Rod 14, o...

Embodiment 3

[0031] On the basis of embodiment 1 and embodiment 2, such as Figure 1-Figure 5 As shown, it also includes a sliding frame 18, a second spring 19, a wedge block 20 and a third spring 21, and the upper sliding type of the limit rod 812 is provided with a sliding frame 18 that cooperates with an L-shaped push frame 810. Inside the sliding frame 18 A second spring 19 is wound between the upper inner side of the right side surface and the upper right side surface of the limit rod 812, and the rear end of the lower part of the sliding frame 18 is fixedly connected with a wedge block 20 that cooperates with the slider 15, and the wedge block 20 is located at the bottom of the slider 15. On the left side, a third spring 21 is connected between the inner surface of the slider 15 and the outer surface of the material storage box 7 , and the third spring 21 is sleeved on the hexagonal rod 14 .

[0032] Also comprise rack bar 22, rotating bar 23, guide block 24, rotating block 25 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com