Screening method of under-inflation protection tire supporting rubber, obtained supporting rubber and tire containing supporting rubber

A technology for run-flat tires and a screening method, applied in the field of tire manufacturing, can solve problems such as limited effective data and differences in the use of support rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

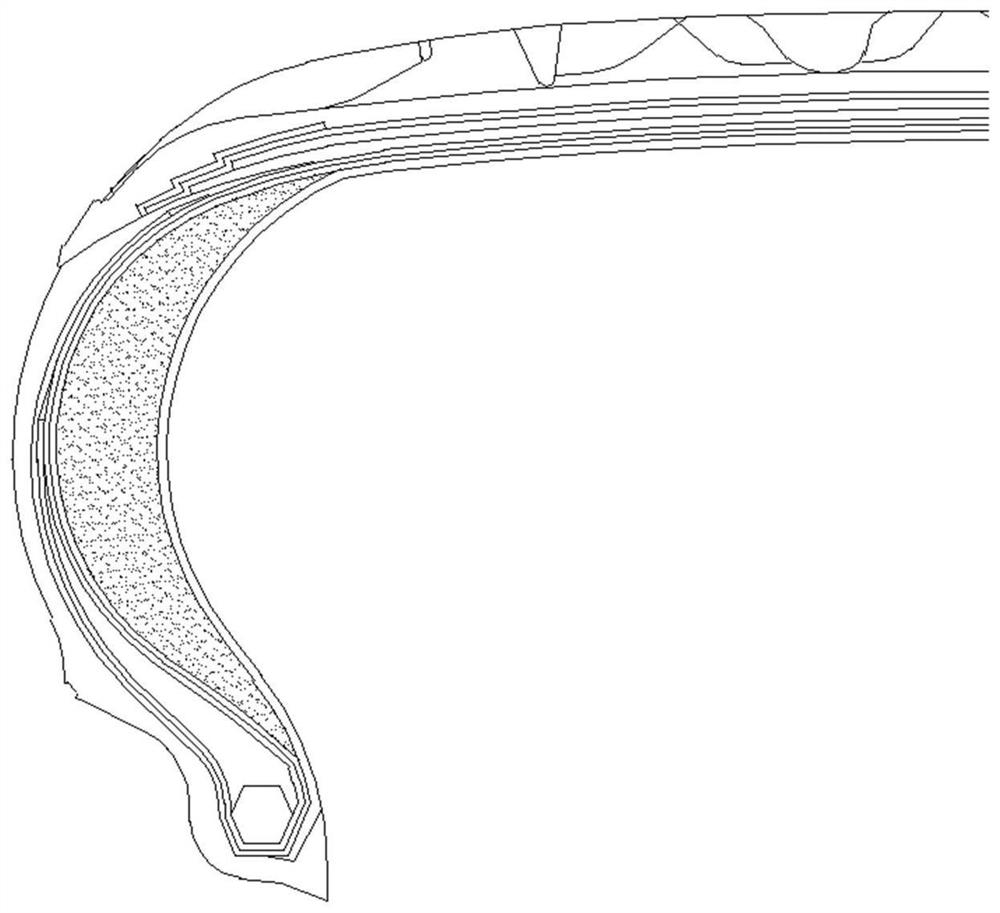

Image

Examples

Embodiment Construction

[0025] The following is a specific example to further illustrate this test method. Taking our company's production specification 225 / 55R17 as an example, it is just an example, and the test conditions are not limited to examples:

[0026] Deformation frequency of support rubber = 10.1hz;

[0027] The actual maximum temperature of the infrared temperature measurement support rubber machine tool is 150°C;

[0028] The maximum deformation is 15%.

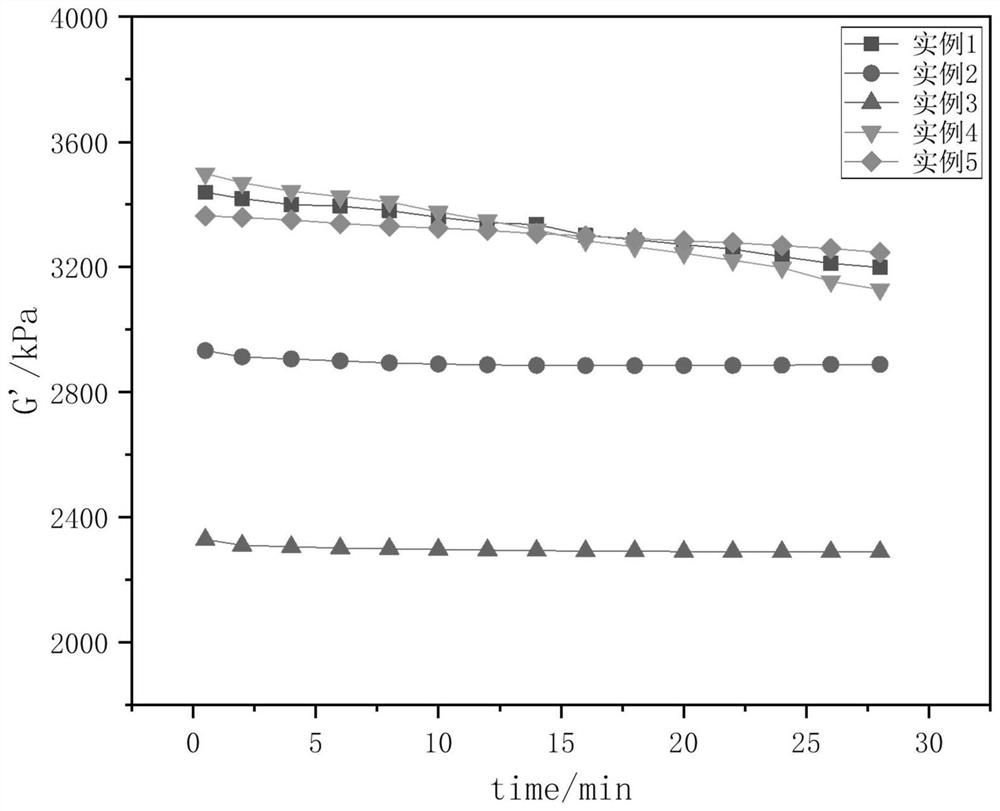

[0029] The conditions for converting the above conditions to time scanning are: vulcanization 160°C*15min, temperature 150°C; strain 15%; frequency 10HZ; time scanning range 0.5-28min. The test can obtain the initial value of the support rubber modulus (G') and the change of the support rubber modulus within 28 minutes. Take the 5 formulas of support rubber developed by our company as an example. Carry out a time scan on the supporting collagen material, take a point every 2 minutes, and record G'. Make a modulus G' / time time diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com