Semiconductor-metal contact resistivity detection method and array substrate

A technology of metal contact and detection method, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, measuring resistance/reactance/impedance, etc., can solve problems such as poor accuracy and achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

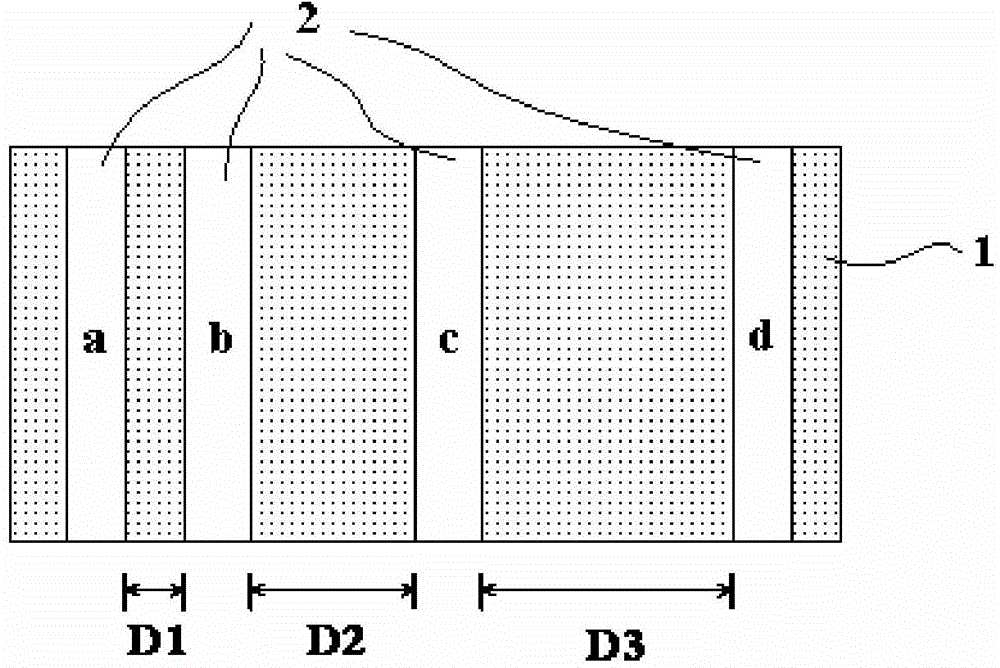

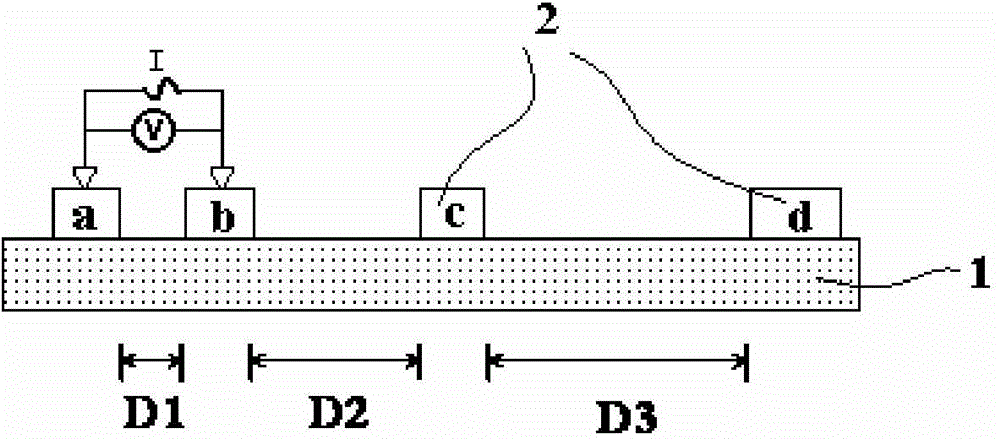

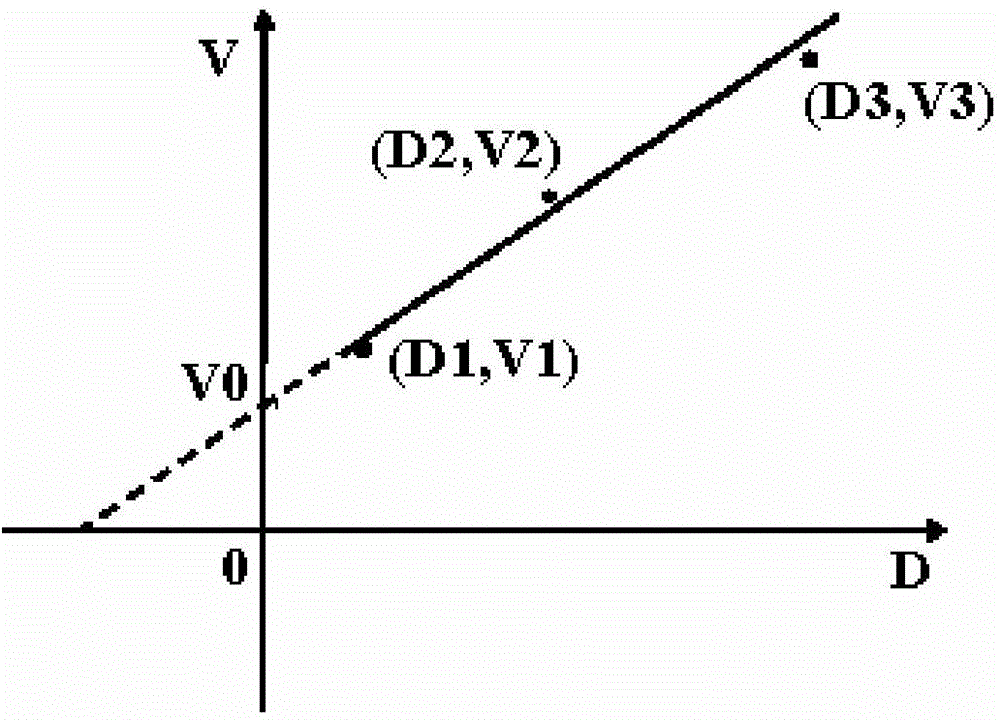

[0032] Such as Figure 1 to Figure 3 As shown, this embodiment provides a semiconductor-metal contact resistivity detection method.

[0033] Wherein, on the semiconductor layer 1 used for the above detection, at least three metal strips 2 with the same shape and size, parallel to each other, spaced apart, and opposite to each other are provided.

[0034] That is, if figure 1 , figure 2 As shown, on the semiconductor layer 1 to be detected, there are a plurality of metal strips 2, the shapes and sizes of these metals are exactly the same, and they are parallel to each other, and each metal strip 2 is arranged in sequence along the same direction, and the adjacent metal strips 2 separated by a certain distance.

[0035] The above detection methods specifically include:

[0036] S100. Optionally, if there is no metal strip 2 on the semiconductor layer 1 to be detected, the metal strip 2 is first formed on the semiconductor layer 1 through a patterning process.

[0037] S101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com