Fire-resistant and high-temperature-resistant control cable and manufacturing method thereof

A control cable and high-temperature-resistant technology, which is applied in the field of power cables, can solve the problems of cables such as fire resistance, poor high-temperature resistance, insufficient tensile and pressure-bearing capabilities, and achieve excellent electrical insulation, improved heat resistance, and extrusion molding The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

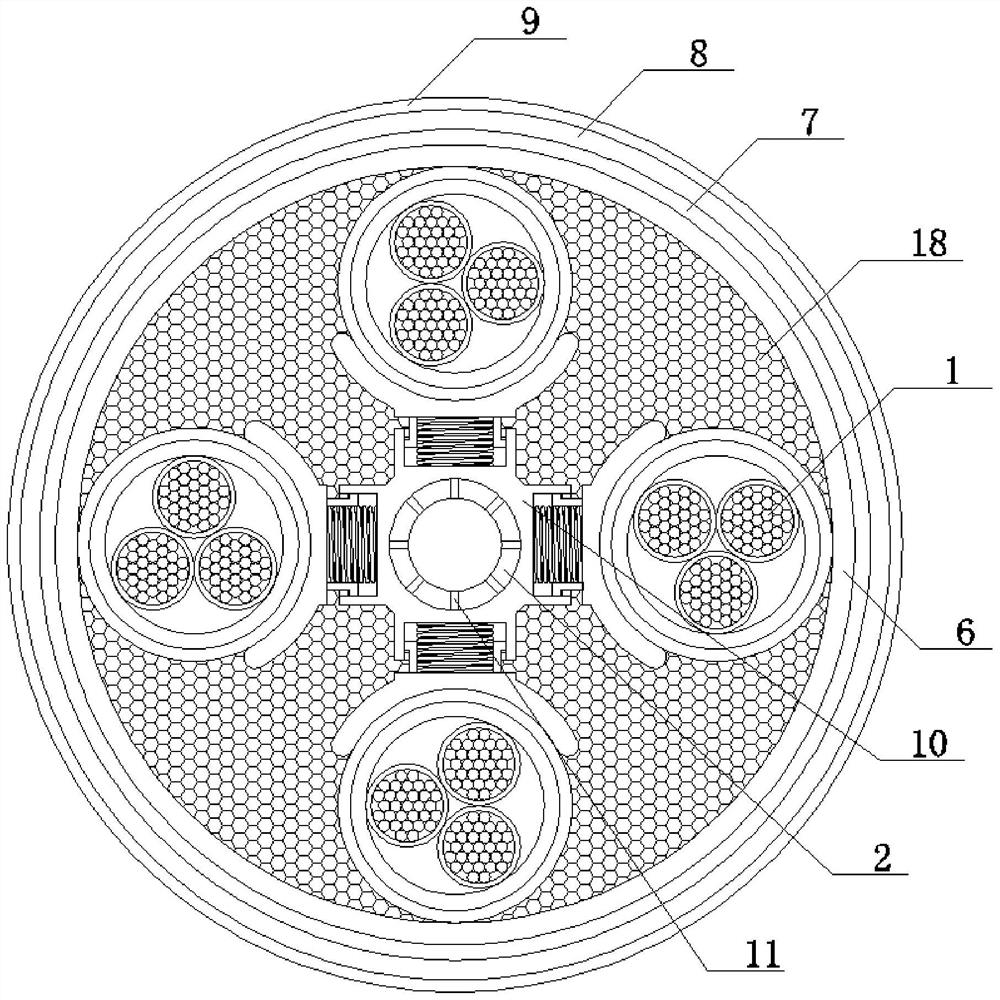

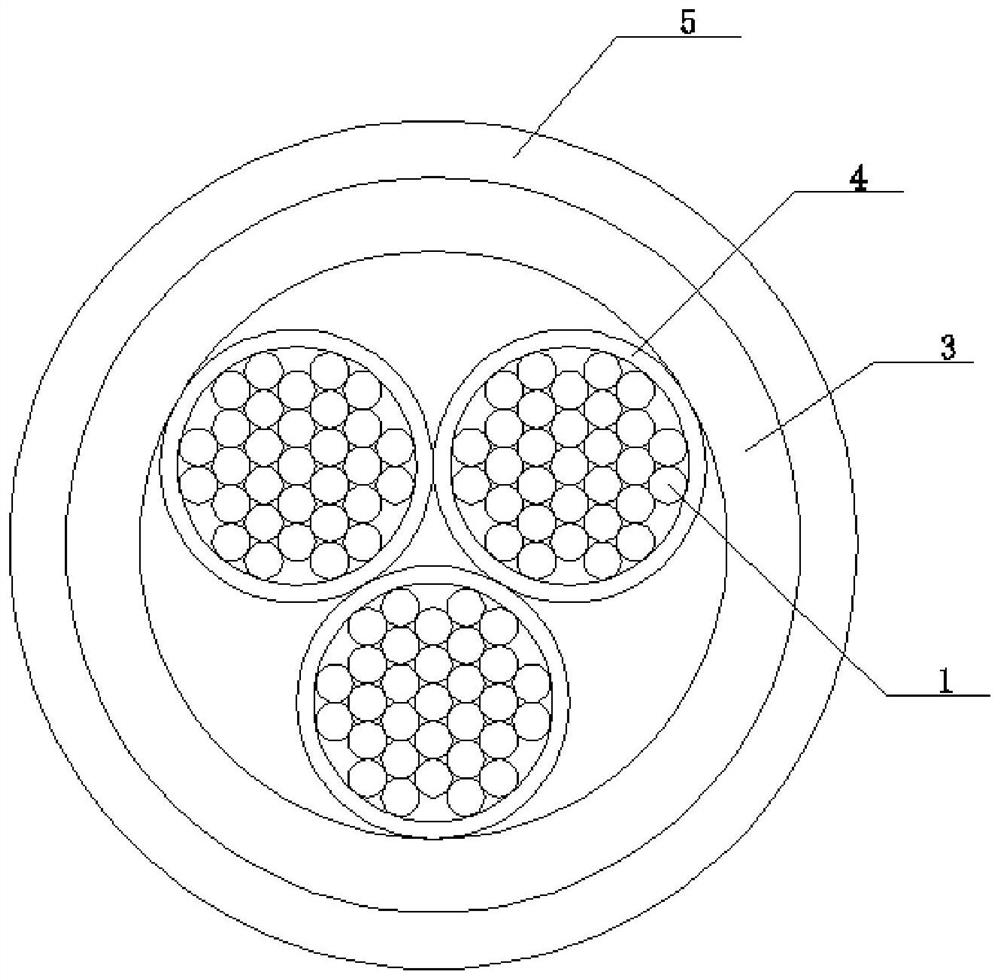

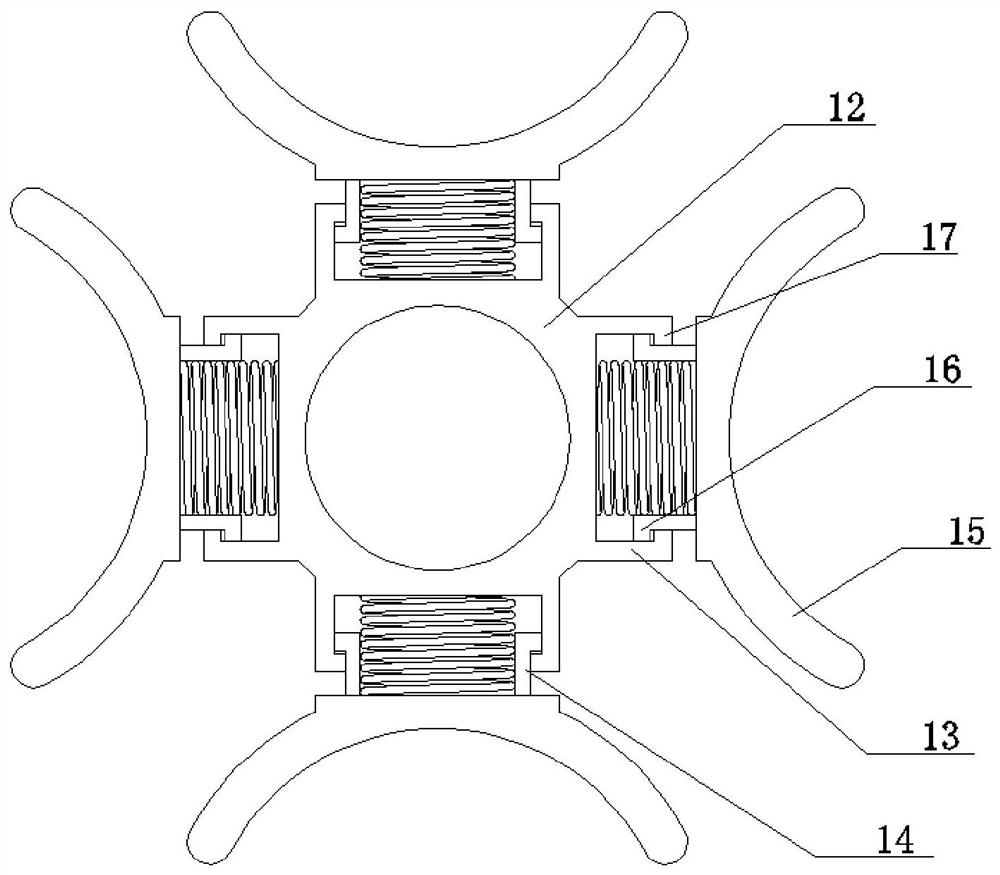

[0037] A fire-resistant and high-temperature-resistant control cable, comprising a plurality of sets of conductors 1, including a heat dissipation strengthening tube 2, the conductor 1 is covered with an insulating layer 4 to form an insulated wire core, and a plurality of insulated wire cores are covered with a braided shielding layer 3, braided The shielding layer 3 is covered with a high temperature resistant loose tube 5 to form the main wire core. Multiple main wire cores are combined and covered with a fireproof heat insulation layer 6, a flame retardant inner sheath 7, a braided armor layer 8 and a flame retardant outer sheath. The sheath 9 and the heat dissipation strengthening tube 2 are located between multiple main wire cores. The heat dissipation strengthening pipe 2 is equidistantly fixedly connected with a plurality of support frames 10 .

[0038] Wherein, the heat dissipation strengthening tube 2 is a polytetrafluoroethylene hose, and the outer peripheral wall of...

Embodiment 2

[0046] A method for preparing a fire-resistant and high-temperature-resistant control cable, comprising the following specific implementation steps:

[0047] Step 1, twisting a plurality of nickel-plated copper wires to form a conductor 1;

[0048] Step 2, extruding a layer of ceramic silicon rubber on the outer periphery of the conductor 1 to form an insulating layer 4, and the insulating layer 4 and the conductor 1 form an insulating core;

[0049] Step 3: Twisting a plurality of insulated wire cores to form an encapsulation body and covering the braided layer of silver-plated copper wire to form the braided shielding layer 3; the braided shielding layer 3 is covered with a high-bulk glass fiber tube, and coated with oxidized Iron-red silica gel forms a high-temperature-resistant loose tube 5; the package body, braided shielding layer 3, and high-temperature loose tube 5 form the main core;

[0050] Step 4: Set a plurality of ventilation holes 11 on the polytetrafluoroethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com