Speed-controllable magnetic drive power generation system

A magnetic drive and power generation system technology, applied in electrical components, electromechanical devices, etc., can solve the problems of difficult rotation speed of magnetic drive devices, reducing enterprise efficiency, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

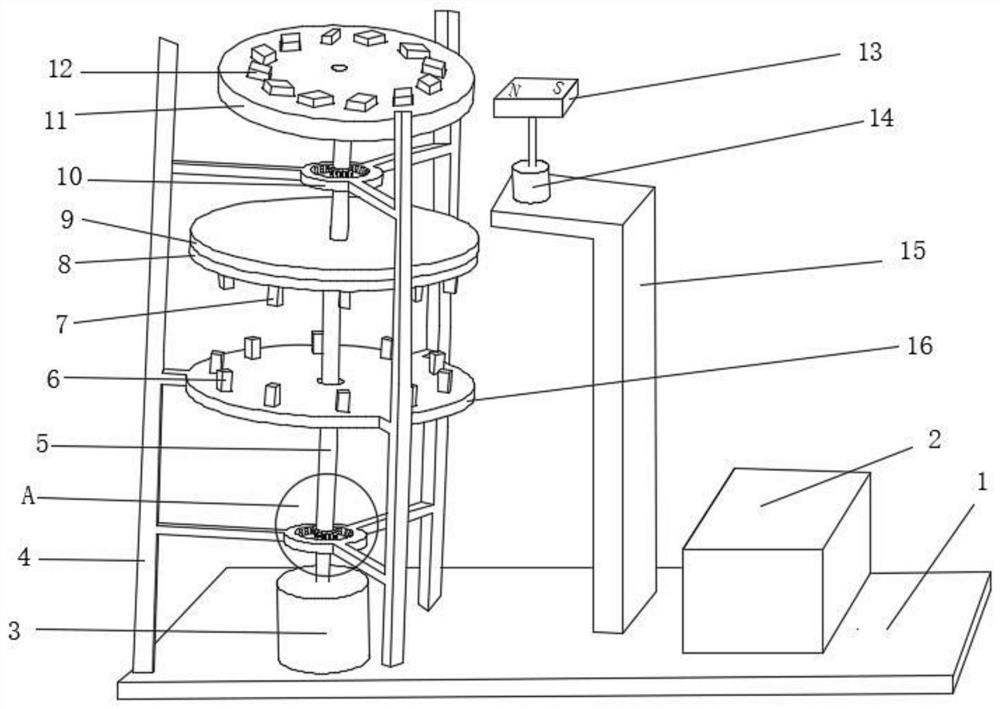

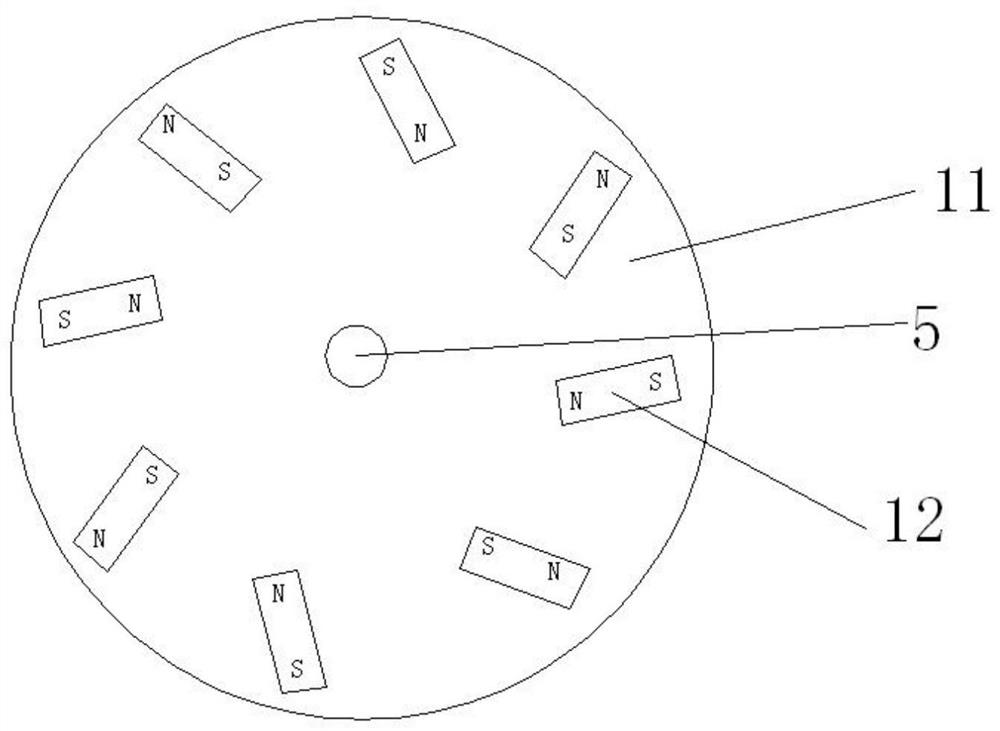

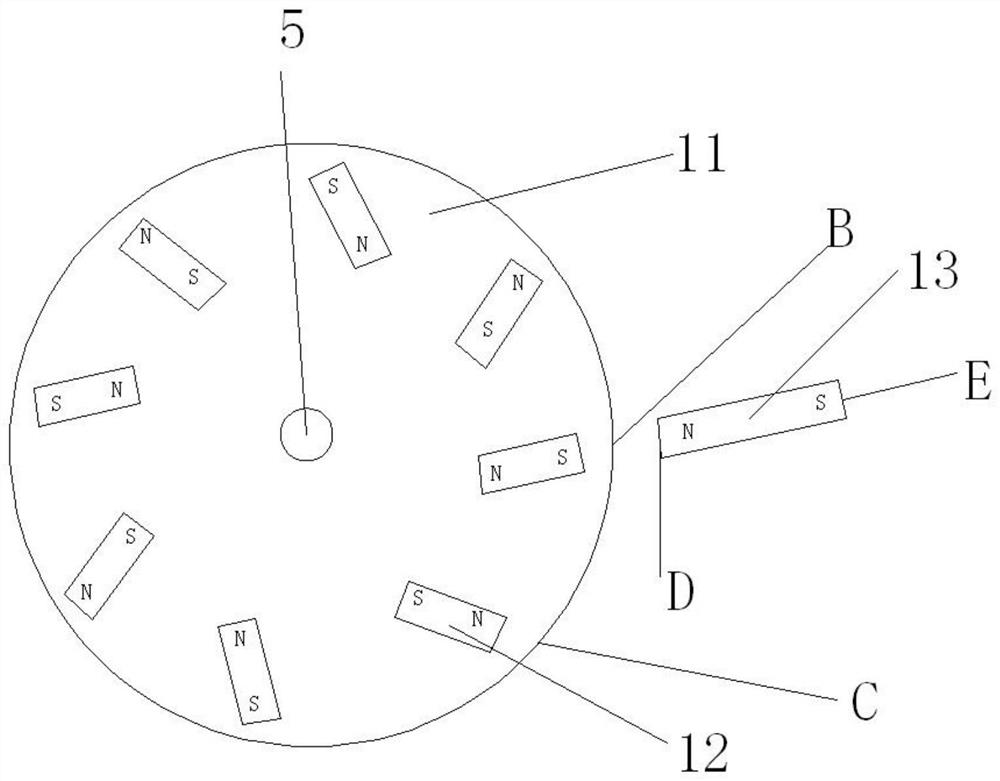

[0029] Such as Figure 1-4 As shown, the embodiment of the present invention provides a controllable speed magnetic drive power generation system, including a base 1, a support frame 4, a generator 3, a magnetic drive device, a central shaft 5, and a magnetic distance control component; the generator 3 is located on the base 1; the magnetic force distance control part includes an annular fixed mount 10 and a plurality of first magnets 18, and a plurality of the first magnets 18 are fixedly installed on the inner surface of the annular fixed mount 10; the circular The annular fixed frame 10 is fixedly connected with the support frame 4; the central shaft 5 passes through the ring center of the annular fixed frame 10, and the bottom of the central shaft 5 is fixedly connected with the rotor of the generator 3, and the central shaft 5. The top is fixedly connected with the magnetic driving device; the outer surface of the central shaft 5 is fixedly installed with a plurality of s...

Embodiment 2

[0043] Such as Figure 5 As shown, the embodiment of the present invention provides a speed-controllable magnetic drive power generation system. The difference from the first embodiment is that the number of drive heads 13 in this embodiment is two groups, and the drive heads 13 surround the rotating disk 11 evenly. Distribution; each group of drive heads 13 corresponds to one drive motor 14 . The two driving heads 13 simultaneously drive the rotating disk 11, so that the driving force to the rotating disk 11 is more sufficient.

[0044] Further, the number of the driving heads 13 may be more than two groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com