Electro-hydraulic unit

A hydraulic unit, electronic technology, applied to components with teeth, liquid variable displacement machinery, fluid pressure actuators, etc., can solve problems such as high development and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

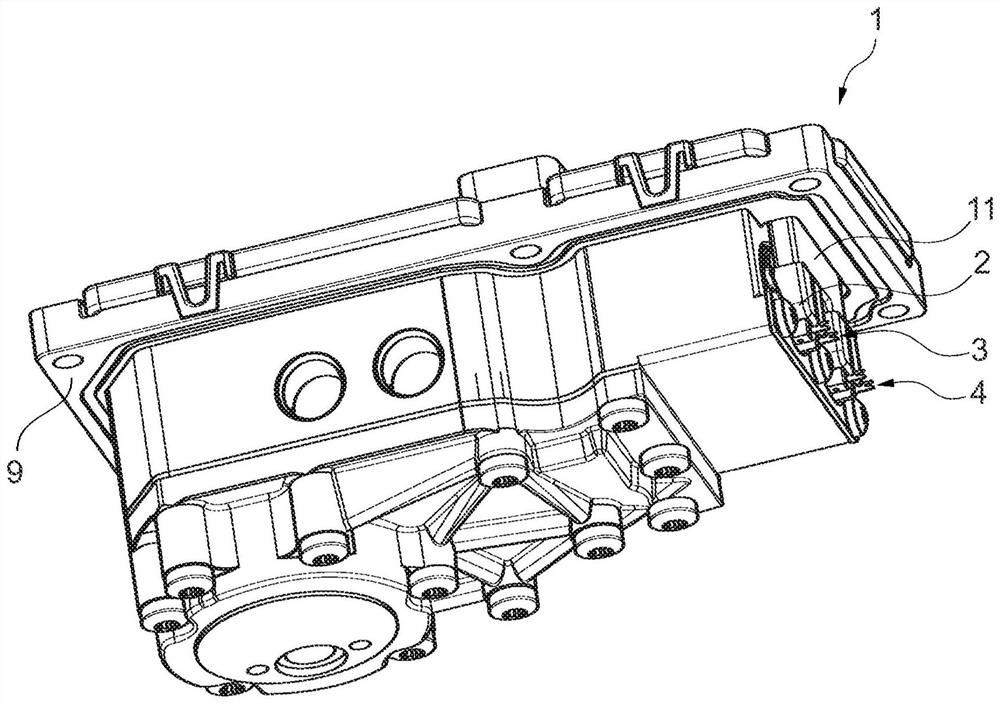

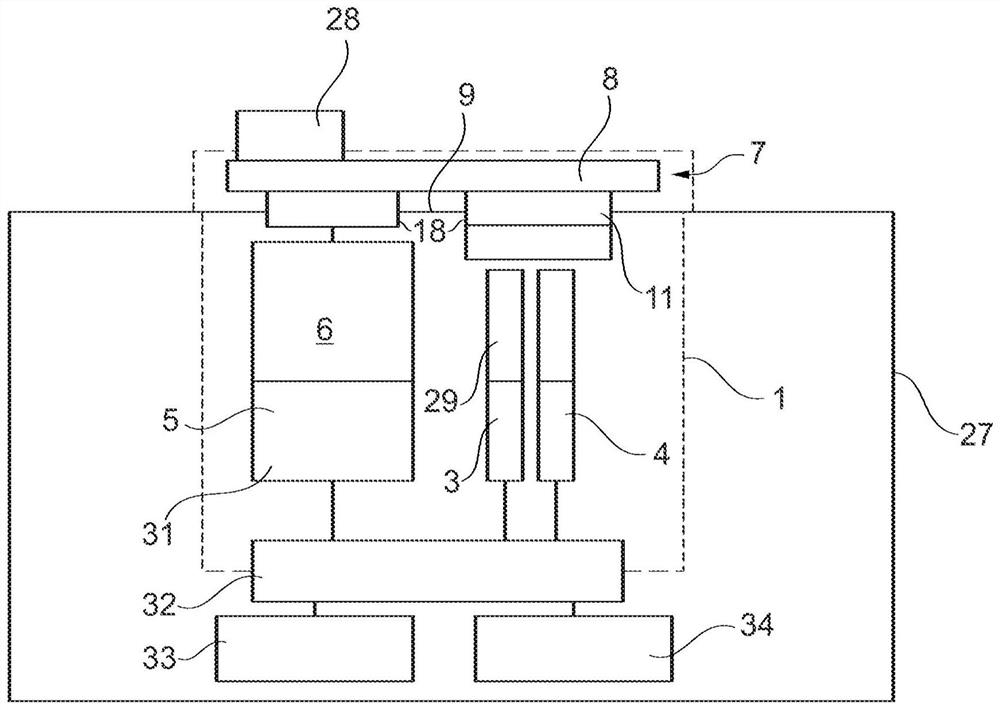

[0031] figure 1 A first variant of the electrohydraulic unit 1 is shown schematically in perspective from the outside. The electrohydraulic unit 1 has a housing 9 , which here is an injection-moulded aluminum housing. exist figure 1 , the housing 9 is open in the region of the crimping element 11 . The first hydraulic valve 3 and the second hydraulic valve 4 pass through the housing 9 in this region. The first hydraulic valve 3 and the second hydraulic valve 4 each have an electromagnet 2 . The first hydraulic valve 3 and the second hydraulic valve 4 are solenoid valves which are electrically conductively connected via crimp elements 11 to the PCB 8 , not seen here, of the electrohydraulic unit 1 .

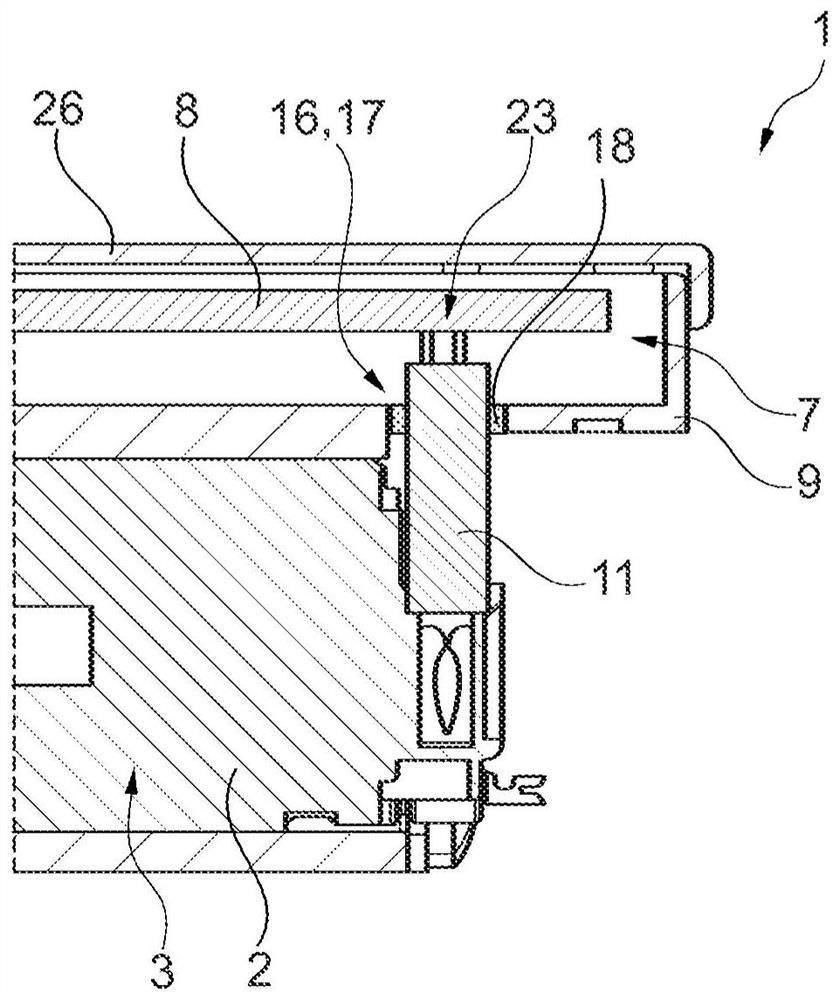

[0032] figure 2 A first variant of the electrohydraulic unit 1 in the region of the crimping element 11 is shown in longitudinal section. The PCB 8 of the control unit 7 of the electrohydraulic unit 1 is arranged in the housing 9 . The PCB 8 has a crimp area 23 with a contac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap