Device for storing molten aluminum and flowing hole plugging method

A technology of aluminum liquid and flow eye, which is applied in the field of aluminum liquid storage device and flow eye plugging, which can solve the problems of loose flow, large safety risk, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

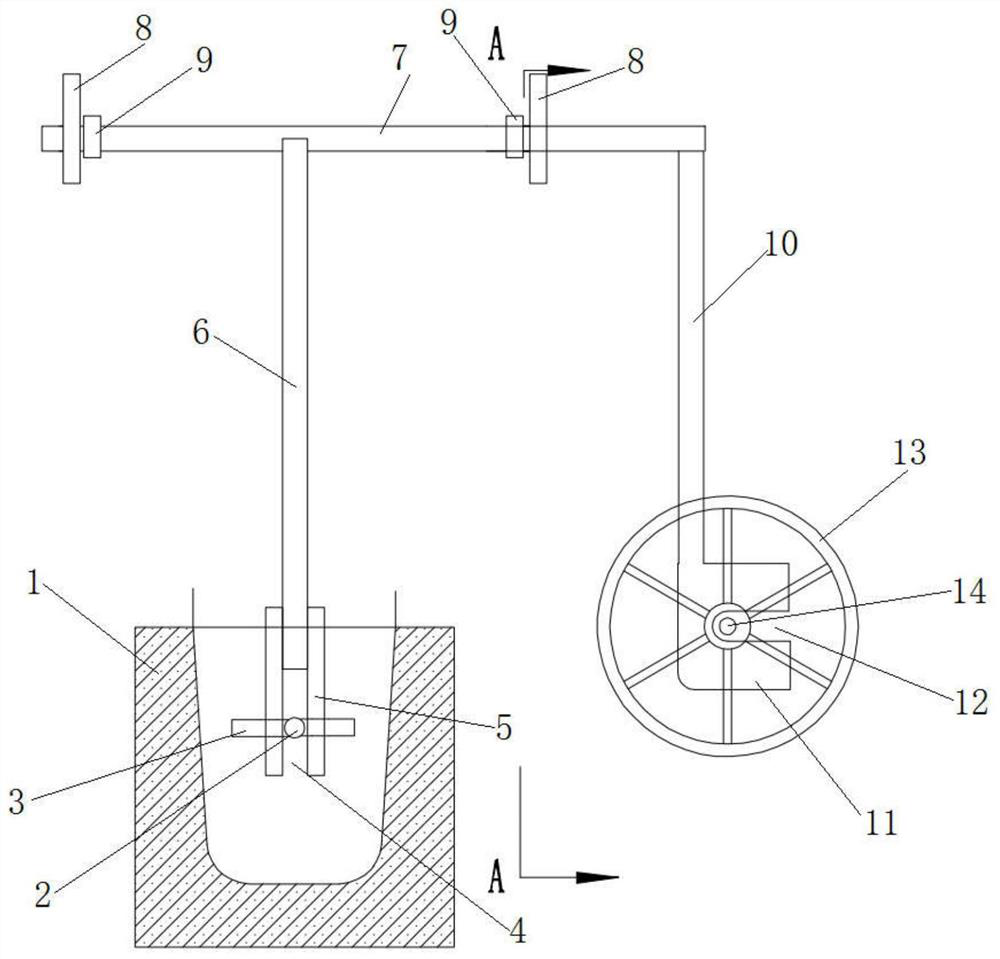

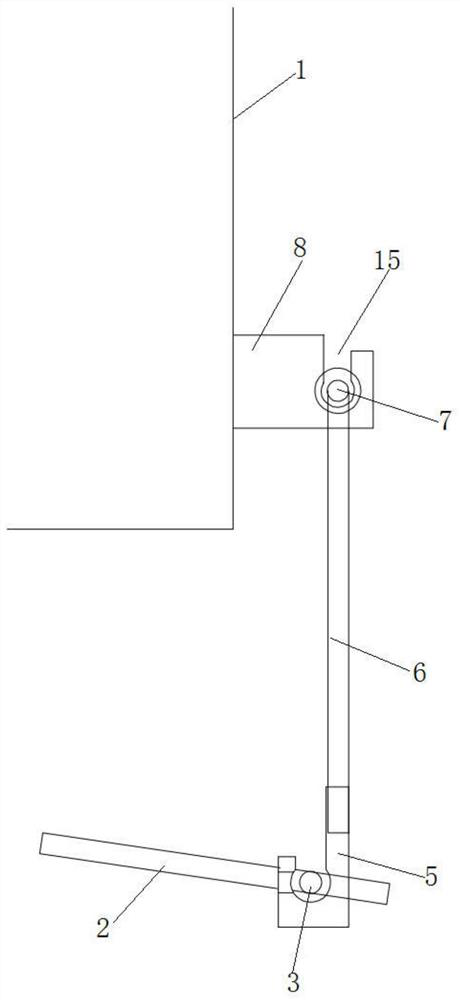

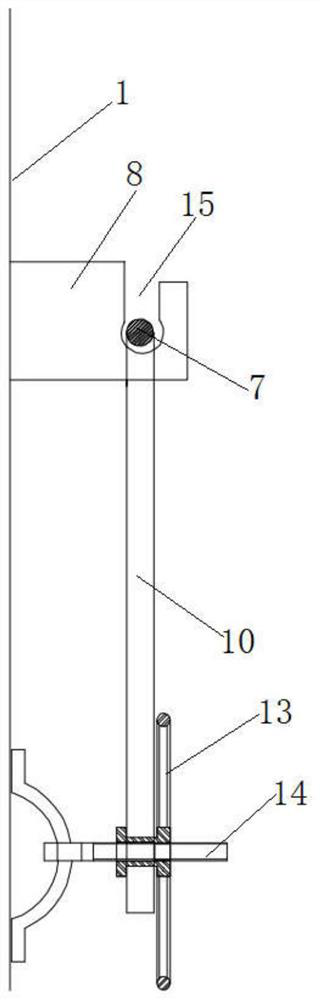

[0037] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments. It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. For the convenience of description, if the words "up", "down", "left", and "right" appear in the following, they only indicate that they are consistent with the upper, lower, left, and right directions of the drawings themselves, and do not limit the structure.

[0038] An aluminum smelting furnace, comprising a body, a cavity for storing molten aluminum and a flow hole communicating with the cavity; and

[0039] A drill rod, one end of which is detachably inserted into the flow eye, and the other end extends outside the body, a section of the drill rod extending outside the body is provided with a pressure rod perpendicular to the drill rod, and both ends of the pressure rod extend To ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com