Improved left auricle occluder

An occluder and sealing disc technology, which is applied in the field of medical devices, can solve problems such as surgical failure and increase the risk of thrombosis, and achieve the effects of reducing the risk of puncture, effectively and reliably sealing, and eliminating local stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

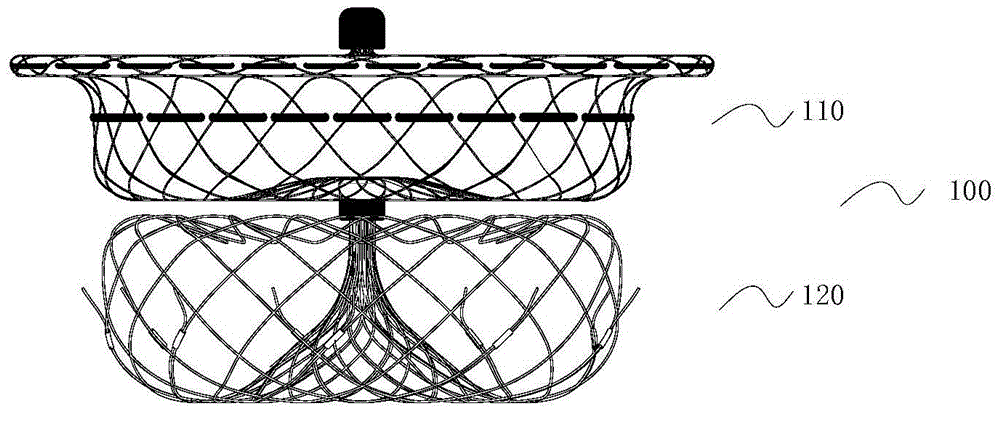

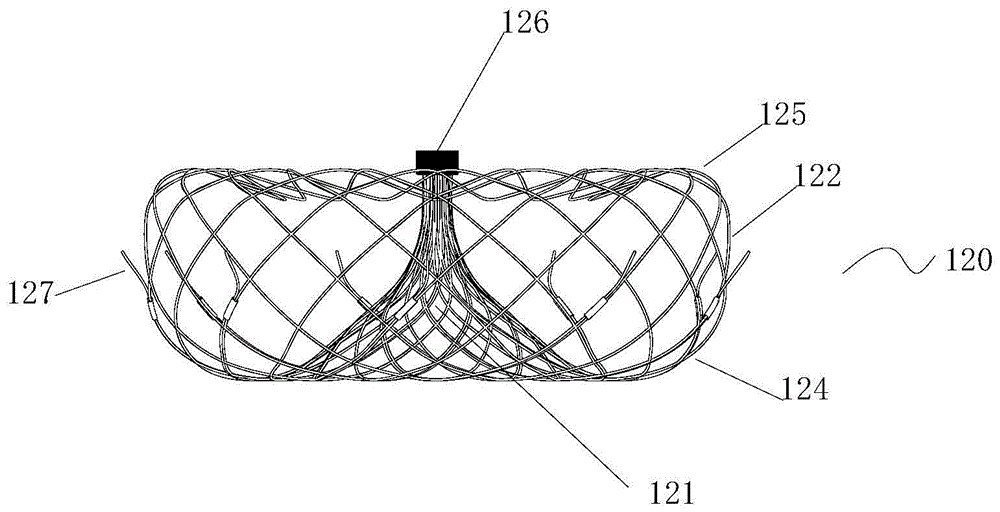

[0097] Such as figure 1 As shown, the left atrial appendage occluder 100 provided by the present invention is composed of a sealing disc 110 and an anchoring device 120 .

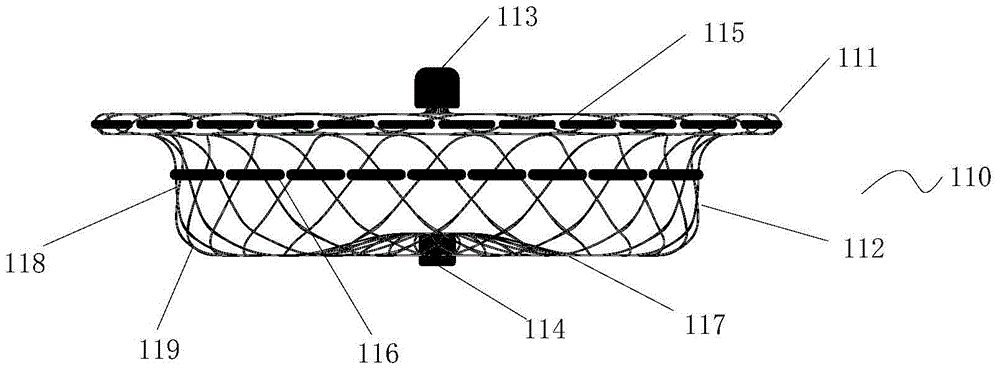

[0098] The sealing disc 110 is a mesh structure braided by nickel-titanium wire, such as figure 2 As shown, the sealing disc 110 is composed of a disc surface 111 and a waist 112, a first fixed end 113 is provided at the center of the disc surface, a second fixed end 114 is provided at the center of the waist 112, and a layer of PET flow blocking film 115 is sewn inside the disc surface. A layer of flow blocking film 116 is sewn inside the waist portion 112 .

[0099] The first fixed end 113 is used to connect with the delivery device, and the second fixed end 114 is connected with the anchoring device 120 .

[0100] Such as figure 2 As shown, the waist 112 includes a diffusion section 117 radiating outward from the second fixed end 114, and a cylindrical body section 118 on the periphery of the diffus...

Embodiment 2

[0122] The difference between this embodiment and Embodiment 1 is that each nickel-titanium wire 2221 used to form the barb is connected to one of the inverted V-shaped nickel-titanium wires 2222 in the anchoring mesh frame by welding, and the welding area The length of 2223 is 2 mm, and the welding area 2223 is close to the apex 2224 where the two sides of the inverted V-shaped nickel-titanium wire intersect. The end 2225 of the nickel-titanium wire 2221 extending out of the welding area 2223 forms a barb 227, and the length of the end 2225 is 2 mm ( Figure 11b In H2=2mm), the distance between the end point 2226 of the end portion 2225 and the apex 2224 of the inverted V-shaped nickel-titanium wire is 8mm, as Figure 11a , Figure 11b , Figure 12a , Figure 12b shown.

Embodiment 3

[0124] The difference between this embodiment and Embodiment 1 is that the total length of each nickel-titanium wire 3221 used to form the barb is 5 mm, and the nickel-titanium wire 3221 is divided into a fixed section and a free section, and the fixed section passes through the steel sleeve 3223 and the free section. The nickel-titanium wire 3222 of the anchoring device frame is connected together, the length of the fixed section is 3mm, and the fixed section is completely located inside the steel sleeve 3223; is 2mm (ie Figure 13b In H3=2mm), the distance between the end point 3226 of the free section 3225 and the apex 3224 of the inverted V-shaped nickel-titanium wire is 8mm, as Figure 13a , Figure 13b , Figure 14a , Figure 14b shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com