Transportation flatcar

A flat car and car body technology, which is applied in the field of auxiliary devices for flat car transportation on port lines, and can solve problems such as deformation of side beams and side doors, operator injury, and impact on side beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

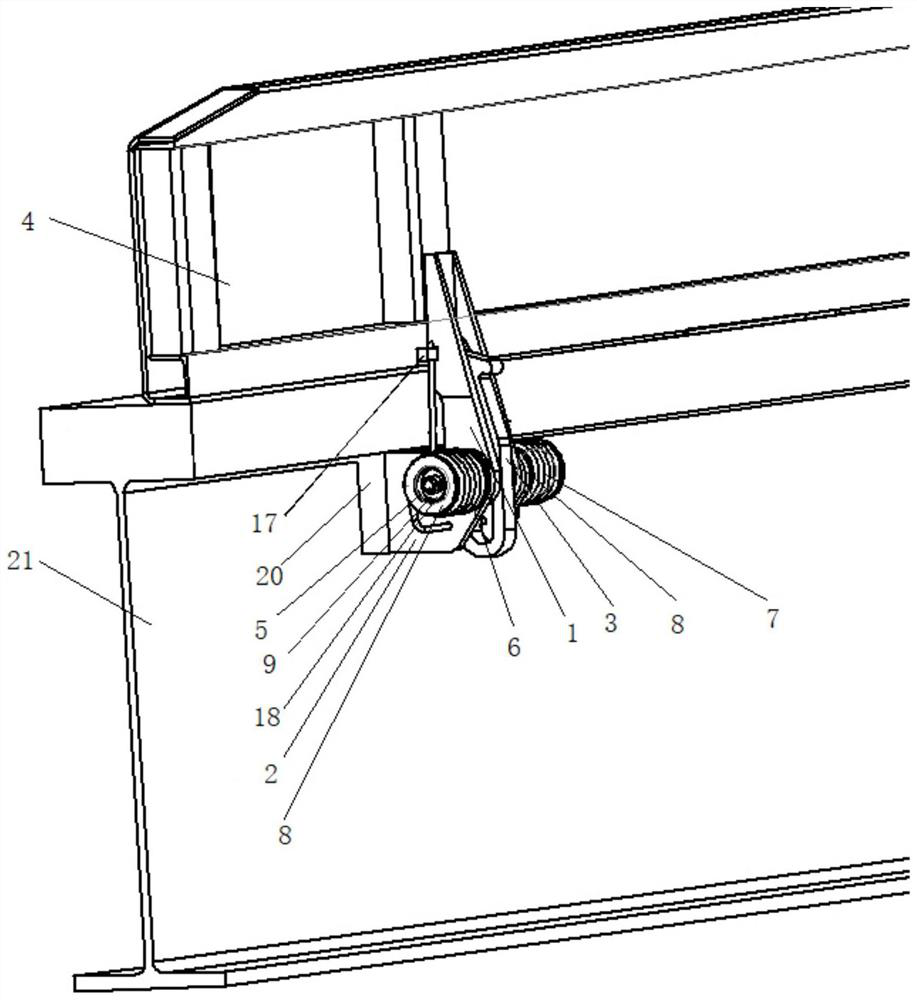

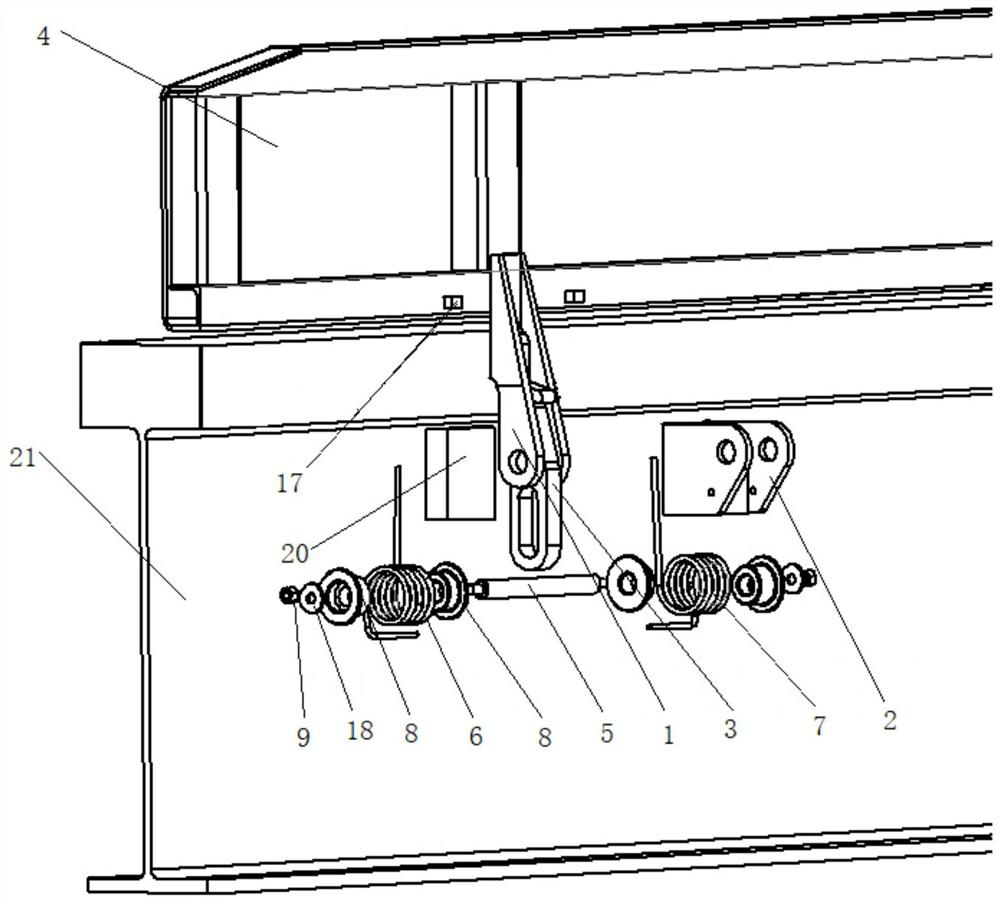

[0031] Such as figure 1 and figure 2 , a transport flat car, including a car body, a buffer device and a side door 4, the side door is installed on the upper surface of the side beam 21 of the car body.

[0032] Wherein, the buffer device includes a connecting hinge 1, a hinged seat 2, an iron stop 3, a compression nut 9, and two arched seats 17.

[0033] The hinged seat 2 is fixed on the backing plate 20, the backing plate 20 is fixed on the side beam 21, and the upper end of the connecting hinge 1 is fixed on the side door 4; set, and connected through the hinge pin 5; the hinge pin 5 is sleeved with a first spring 6 and a second spring 7, the first spring 6 and the second spring 7 are respectively located on both sides of the hinge seat 2, the first spring 6 and the The direction of rotation of the second spring 7 is opposite.

[0034] Both ends of the arched seat 17 are fixed on the side door 4, and the two arched seats 17 are respectively located on both sides of the ...

Embodiment 2

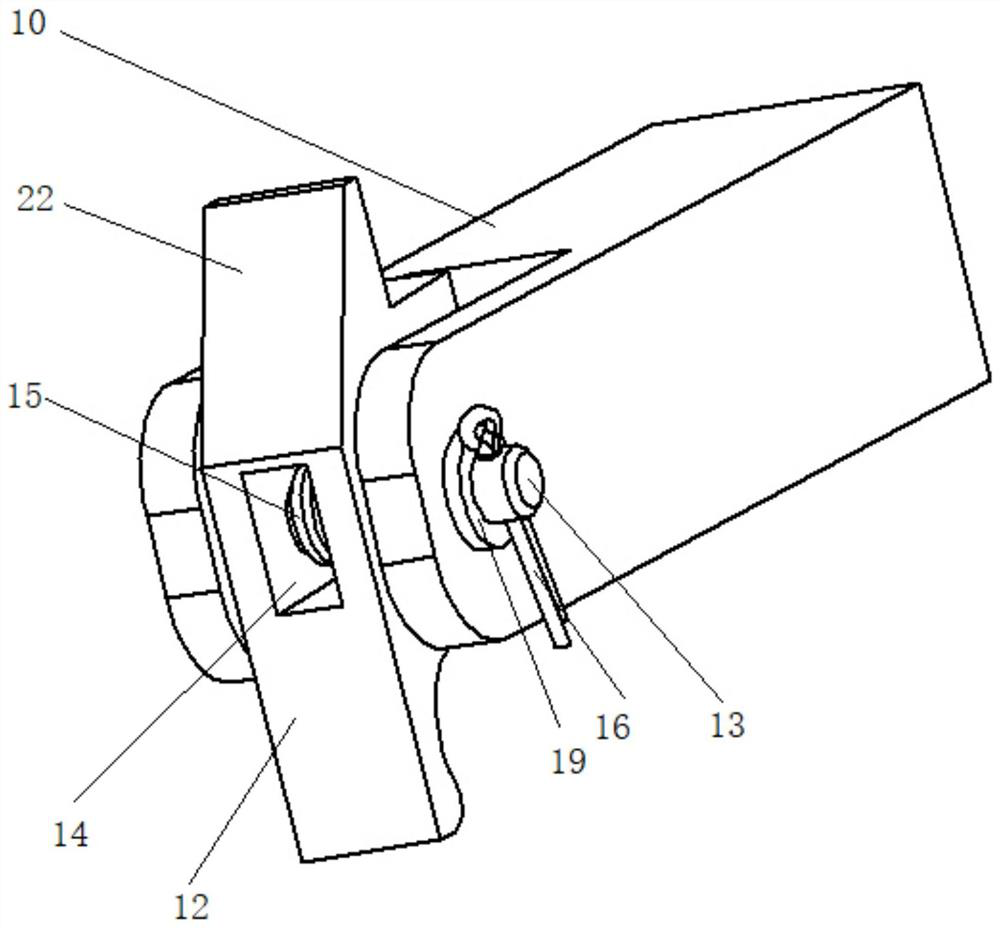

[0038] A buffer device for the side door of a transport flat car, in the case that the other connecting structures are the same as those in the first embodiment, it also includes a limiting device fixed on the lower part of the side beam 21 . Such as image 3 and Figure 4 As shown, the limit device includes a support 10, a stop 12 and a third spring 15. One end of the support 10 is fixed to the lower part of the side beam 21, and the other end is provided with a U-shaped groove 11, and the stop 12 is arranged in the U-shaped groove. 11, the support 10 and the stop 12 are connected through a cylindrical pin 13, the end of the cylindrical pin 13 is provided with a cotter pin 16, and a second washer 19 is also provided between the cotter pin 16 and the support 10; the upper part of the stop 12 The outer side is an inclined surface 22, and a through hole 14 is opened on the stopper 12 located below the inclined surface 22, and the through hole 14 extends from the front side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com