Multifunctional field engineering vehicle

A kind of engineering vehicle and multi-functional technology, applied in the direction of cranes, etc., can solve the problems of low construction efficiency, many types and coordination links, high cost of equipment use and deployment, and achieve the effect of improving work efficiency, compact structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

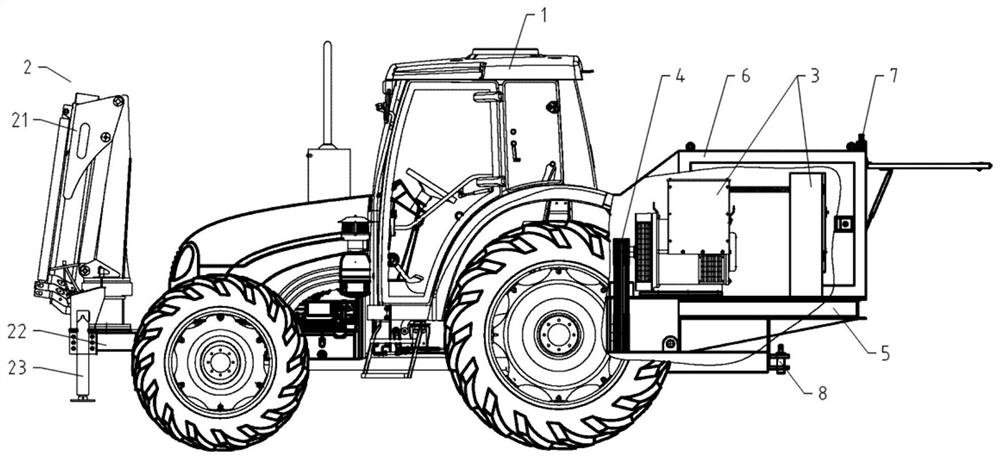

[0028] The present invention provides a multifunctional field engineering vehicle, comprising a vehicle body 1, on which functional components are arranged, the functional components include a crane 2 and a power generating device 3, the crane 2 is arranged on the head of the vehicle body 1, and the power generating device 3 is arranged at the tail of the vehicle body 1;

[0029] The vehicle body 1 is also provided with a transmission component 4 , the power input end of the transmission component 4 is connected to the power source of the vehicle body 1 , and the power output end of the transmission component 4 is respectively connected to the crane 2 and the power generation device 3 .

[0030] Specifically, as shown in the attached figure 1 As shown, the engineering vehicle of the present invention mainly includes a vehicle body 1 and functional parts arranged on the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com