Optical fiber merging jig

A fixture and optical fiber technology, applied in the direction of bundled optical fibers, etc., can solve the problems of non-standard bending and easy breaking of optical fibers, and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be further described in detail below.

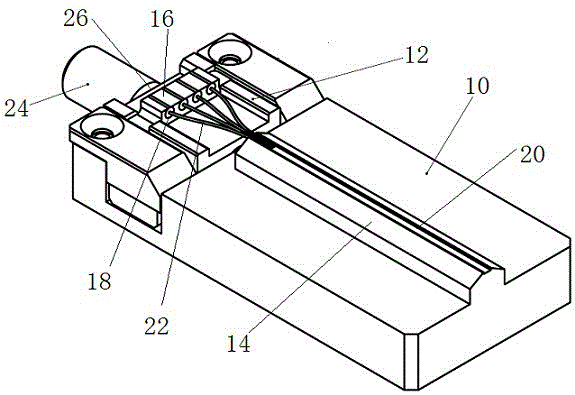

[0013] Such as figure 1 As shown, an optical fiber bundling jig of the present invention includes a base 10 on which a positioning plate 12 and a bundling base 14 are arranged. The positioning plate 12 and the belt base 14 can be integrally formed with the base 10 , or can be fixed on the base 10 by means of screw fixing or the like. In this embodiment, a screw fixing method is adopted, which is convenient for processing, disassembly and replacement, and thus is applicable to the occasion where multiple optical fiber products of different specifications are paralleled. A pressing plate 16 is detachably clamped in the positioning plate 12, and a plurality of positioning holes 18 parallel to each other are arranged on the pressing plate 16, and a groove 20 is arranged on the belt base 14, and the groove 20 is parallel to the positioning holes 18. In this way, several optical fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com