A preparation method of pet modified filler, pet composite material and preparation method thereof

A composite material and modification technology, which is applied in the direction of fibrous filler, dyed high-molecular organic compound treatment, dyed low-molecular organic compound treatment, etc. It can solve the problems of limiting the application of PET composite materials and the general performance of PETVOC, so as to improve VOC performance , the effect of high porosity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

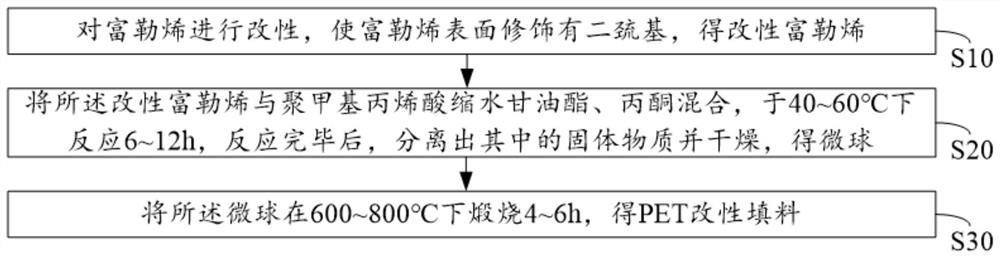

[0044] Polyethylene terephthalate (PET), as a widely used polymer polyester resin, has the advantages of good fatigue resistance, good heat resistance, excellent dimensional stability, etc., but the VOC of PET The general performance limits the application of PET composite materials in some specific fields. In view of this, the present invention proposes a method for preparing PET modified fillers, using modified fullerene with highly active groups and polyglycidyl methacrylate as raw materials to prepare a new type of filler that can significantly improve the performance of PET. Modified filler for material VOC performance, figure 1 Shown is an embodiment of the preparation method of the PET modified filler provided by the present invention. refer to figure 1 Shown, in the present embodiment, the preparation method of described PET modified filler comprises the following steps:

[0045] Step S10, modifying the fullerene so that the surface of the fullerene is modified with...

Embodiment 1

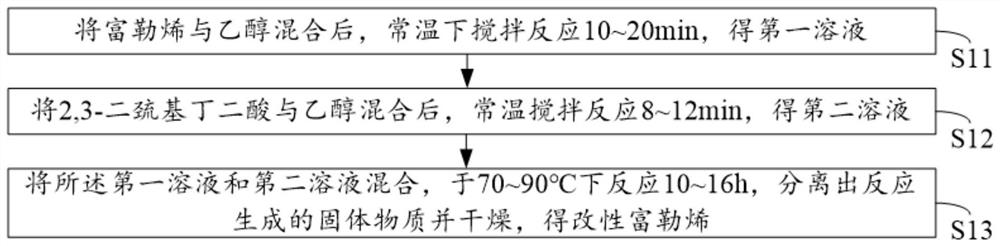

[0067] (1) Weigh 600g fullerene and 2000g ethanol, join in the reactor, stir and react at normal temperature for 10min, obtain the first solution;

[0068] (2) Weigh 400g of 2,3-dimercaptosuccinic acid and 1800g of ethanol, add them into the reactor, stir and react at room temperature for 8min, and obtain the second solution;

[0069] (3) Weigh 700g of the first solution and 100g of the second solution, add them to the reactor, and react at 70°C for 10h. After the reaction is completed, the product solution is suction-filtered, the solid matter is separated and washed, and then placed Dry in a vacuum oven at 60°C for 3 hours to obtain a modified fullerene modified with a dimercapto group;

[0070] (4) Weigh 10g of sodium hexametaphosphate, 1800g of ethanol, 600g of glycidyl methacrylate and 2g of cumene hydroperoxide, add them to the reactor, heat to 80°C for 8 hours, and after the reaction is completed, the product The solution was filtered, the solid matter was separated an...

Embodiment 2

[0074] (1) Weigh 800g fullerene and 2400g ethanol, join in the reactor, stir and react at normal temperature for 20min, obtain the first solution;

[0075] (2) Weigh 600g of 2,3-dimercaptosuccinic acid and 2400g of ethanol, add them into the reactor, stir and react at room temperature for 12min, to obtain the second solution;

[0076] (3) Weigh 900g of the first solution and 200g of the second solution, add them to the reactor, and react at 90°C for 16h. After the reaction is completed, the product solution is suction-filtered, and the solid matter is separated and washed, and then placed Dry in a vacuum oven at 80°C for 5 hours to obtain a modified fullerene modified with a dimercapto group;

[0077] (4) Weigh 30g sodium hexametaphosphate, 2000g ethanol, 800g glycidyl methacrylate and 4g cumene hydroperoxide, add them to the reactor, heat to 100°C for 12h, after the reaction is completed, the product The solution was filtered, the solid matter was separated and washed, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap