Portable pedal down feather discharging mechanism

A portable, pedal technology, applied in the field of down filling, which can solve problems such as affecting production efficiency, trouble, and unstable downfall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

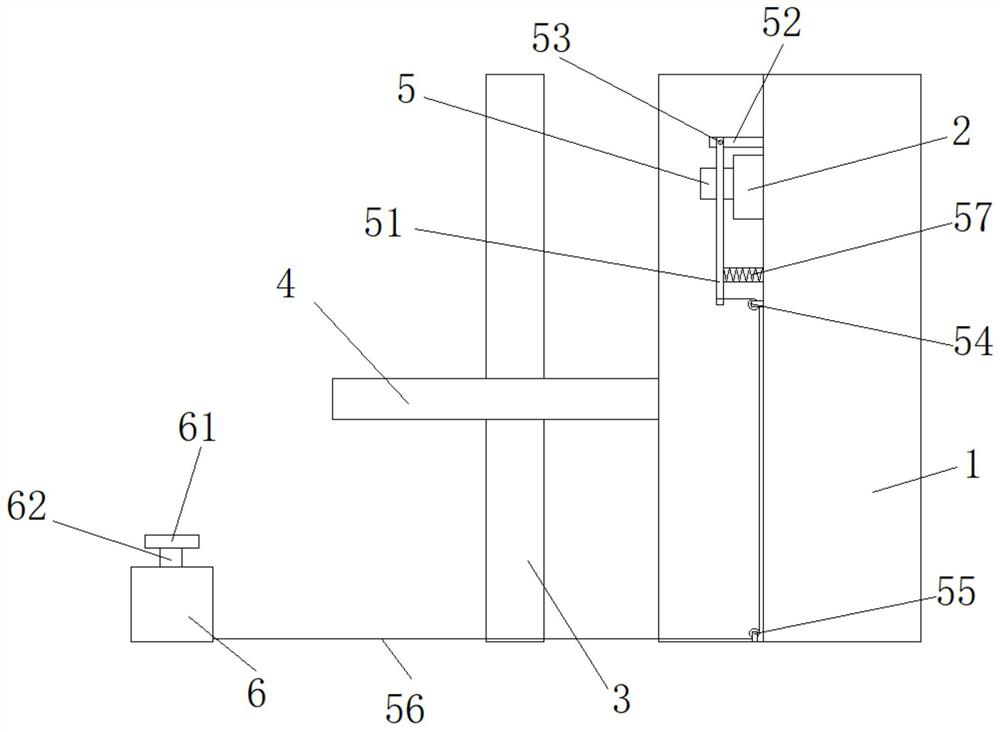

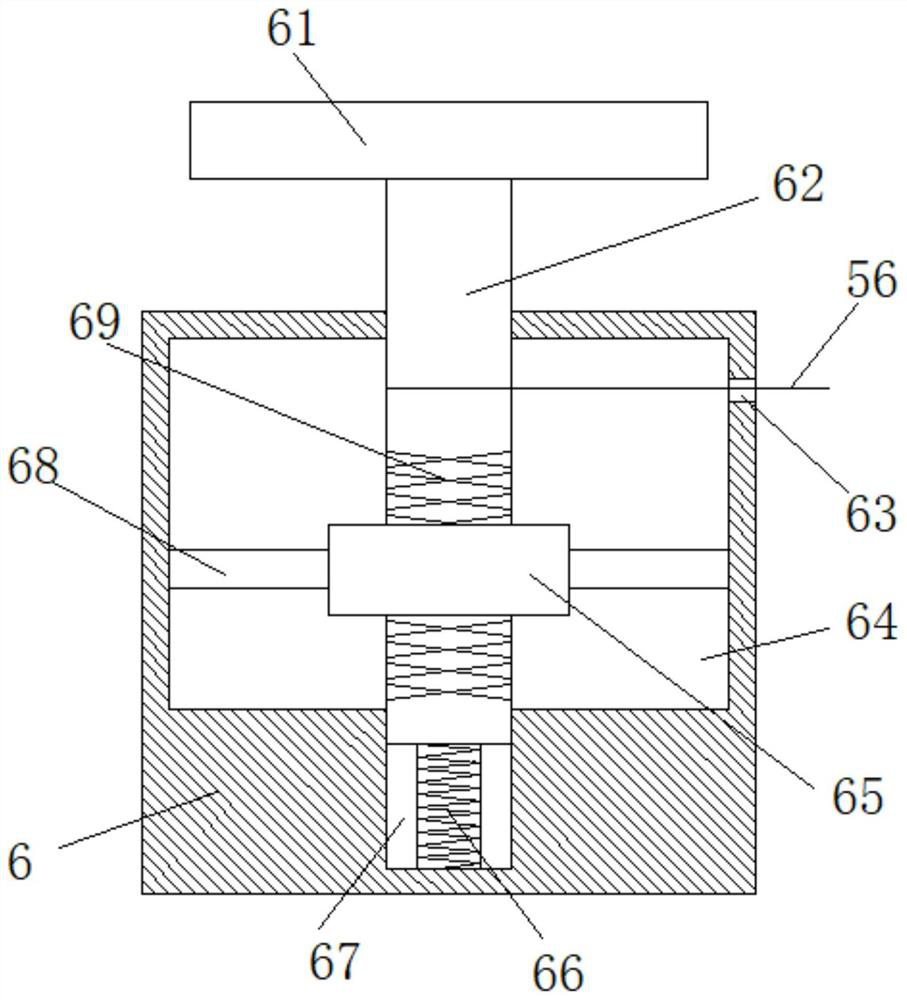

[0019] see Figure 1-2 , a portable foot down down mechanism, applied to a down filling machine, the down filling machine includes a down filling machine main body 1, a switch button 2 arranged on the down filling machine main body 1, a switch button 2 arranged on the down filling machine main body 1 The down filling tube 4 and the partition wall 3 arranged on one side of the down filling machine main body 1, the down filling tube 4 passes through the partition wall 3, and the down down mechanism includes a pressing block 5, a pressing rod 51 and a transmission line 56. The pressing block 5 is arranged on the switch button 2, and the down filling machine main body 1 located at the upper end of the switch button 2 is provided with a positioning rod 52, and the positioning rod 52 is provided with a fixedly connected connecting shaft 53, and the pressing rod The end of one end of 51 is movably connected with the connecting shaft 53, and the pressing block 5 is fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com