Visible large-scale telescopic well fluid-solid-heat coupling natural gas hydrate exploiting experimental simulation device and method

A technology of experimental simulation and hydrate, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems affecting long-term mining efficiency, large heat loss, freezing, etc., and achieve reliable results in commercial mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

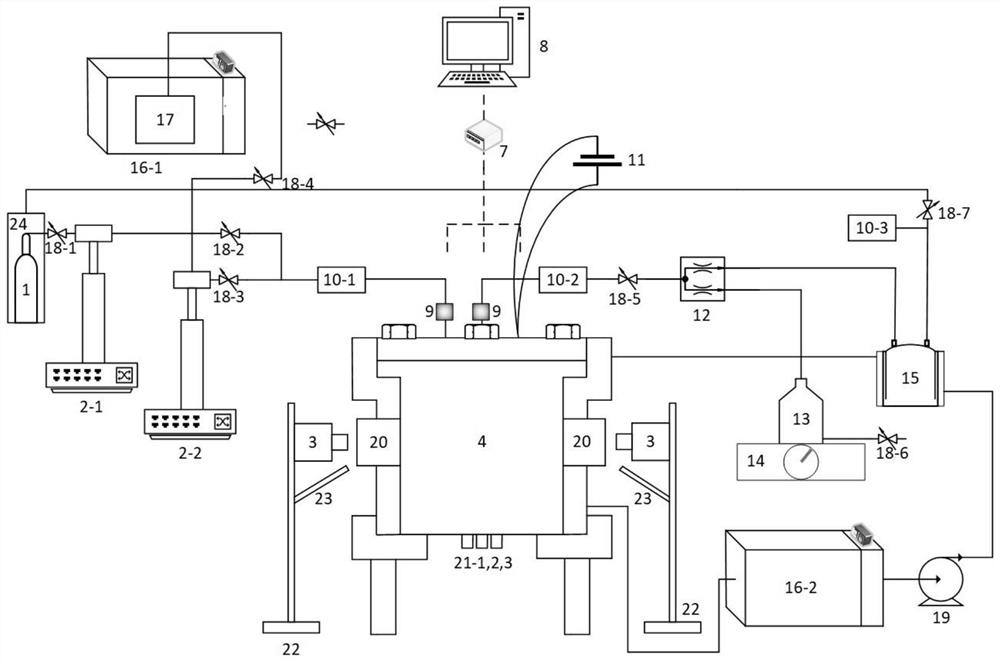

[0024] Such as figure 1 As shown, according to the structure connection of the device, the gas hydrate exploitation experiment of the three wells combined method is carried out by using the cover device;

[0025] (1) Inspection: All valves and pumps are closed to ensure that all devices and pipelines are water-tight and air-tight;

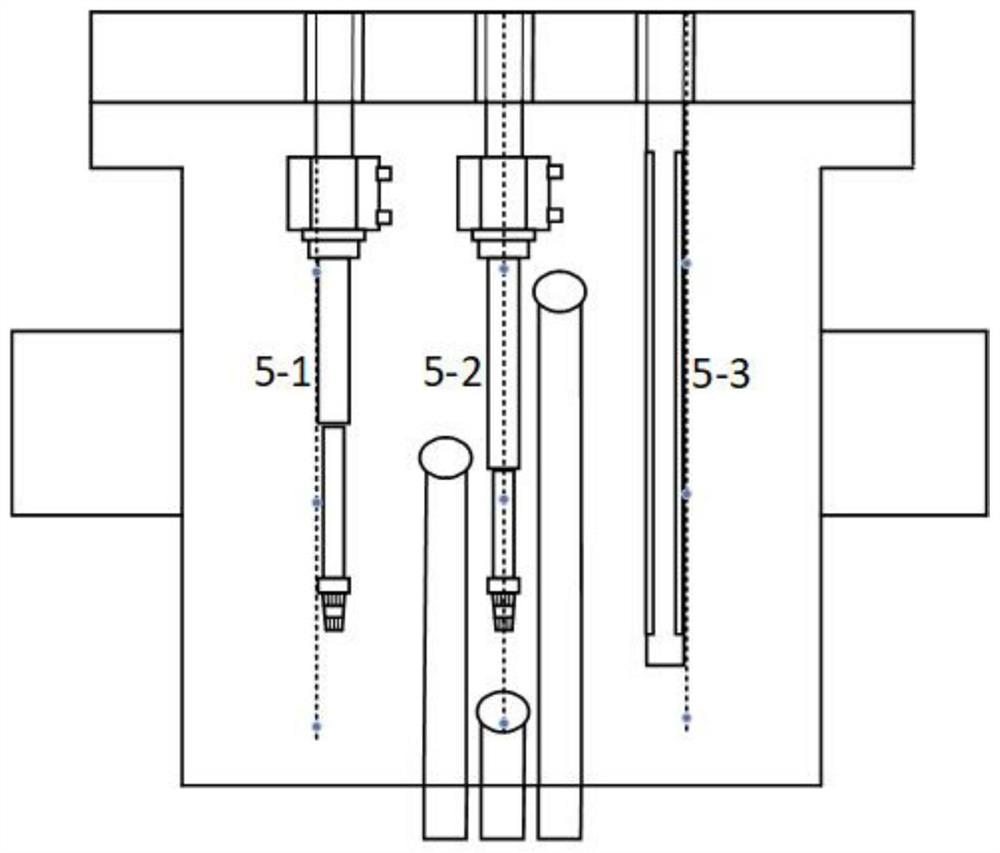

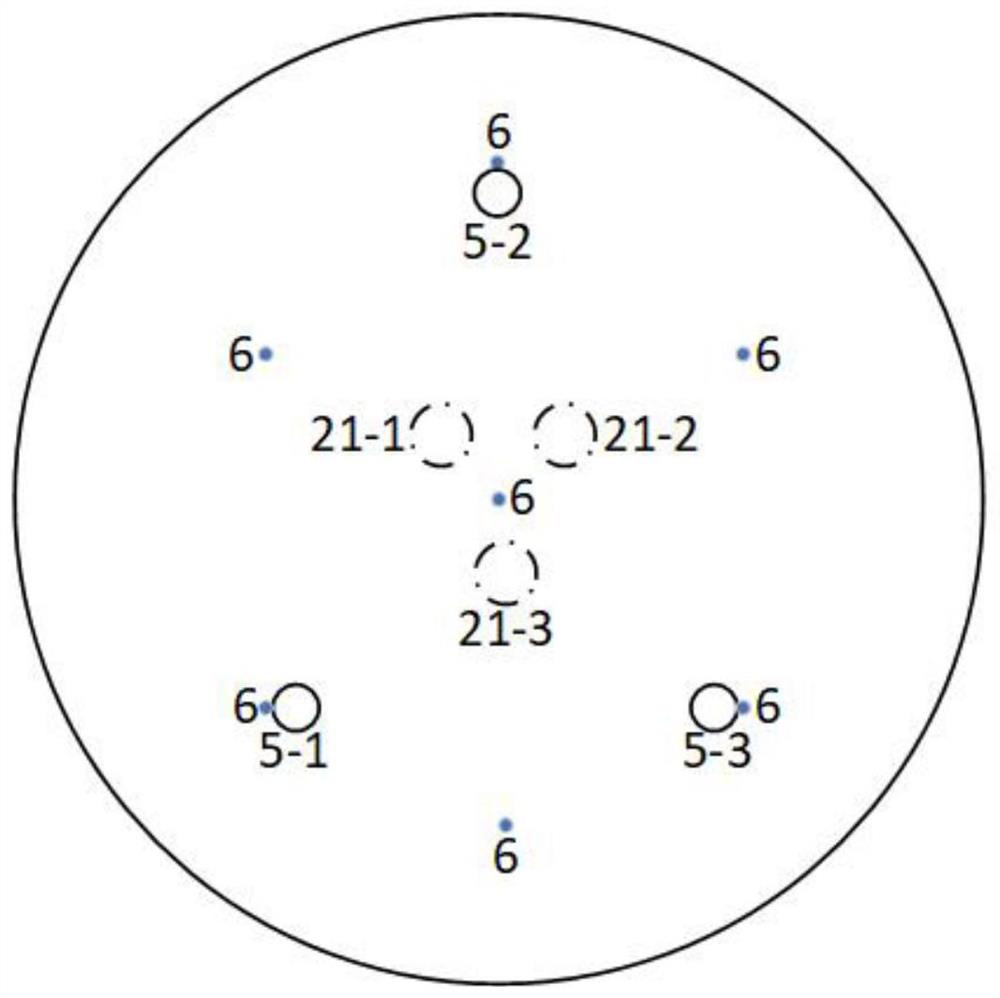

[0026] (2) Formation of natural gas hydrate: use gas saturation to simulate the real natural gas hydrate formation; the volume of glass sand is the volume of the reactor minus the volume of the production well 5 and the high-precision multi-position temperature sensor 6, and then the sand The density calculates the quality of sand, sand is evenly and compactly filled in the reaction kettle 4; Heat injection well mining 5-3 adopts the type in Fig. 2 (a), adopts 100 ohm resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com