Infinitely variable speed transmission mechanism

A transmission mechanism, continuously variable speed technology, applied in transmission, transmission control, mechanical equipment, etc., can solve the problems of troublesome speed regulation, high production cost, slow speed increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

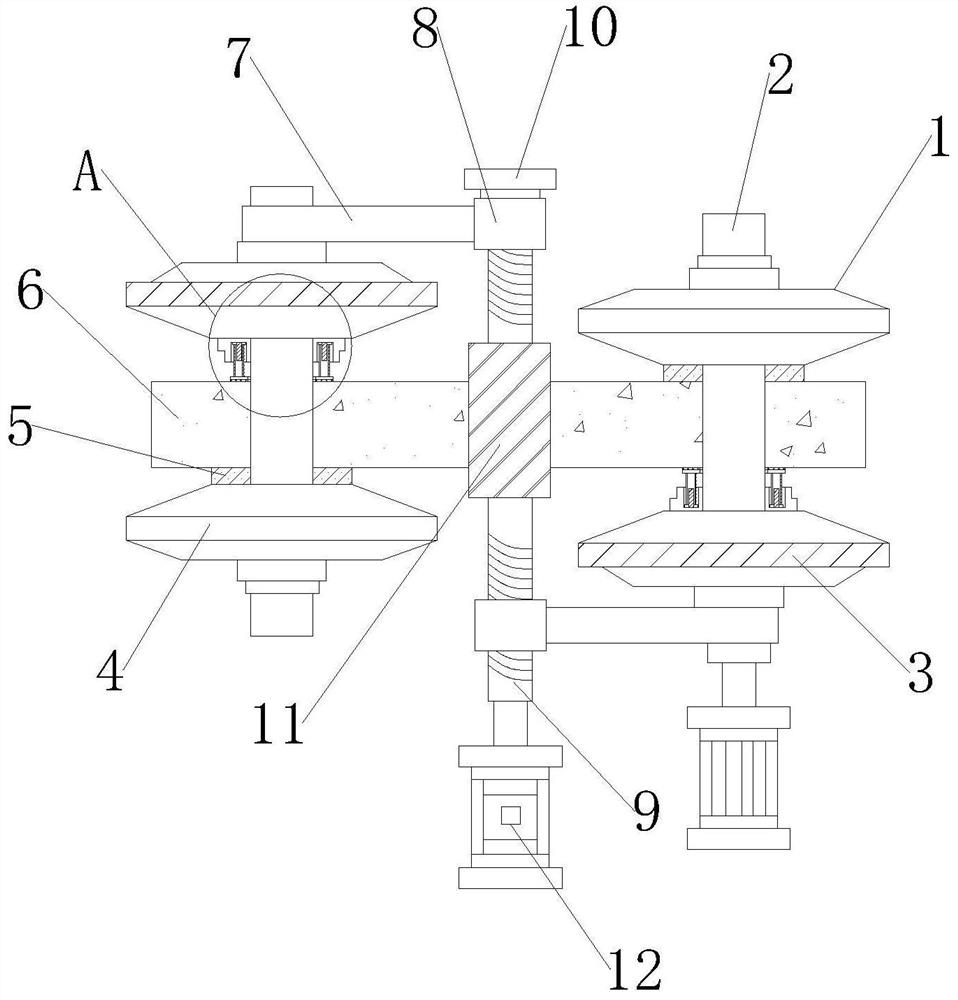

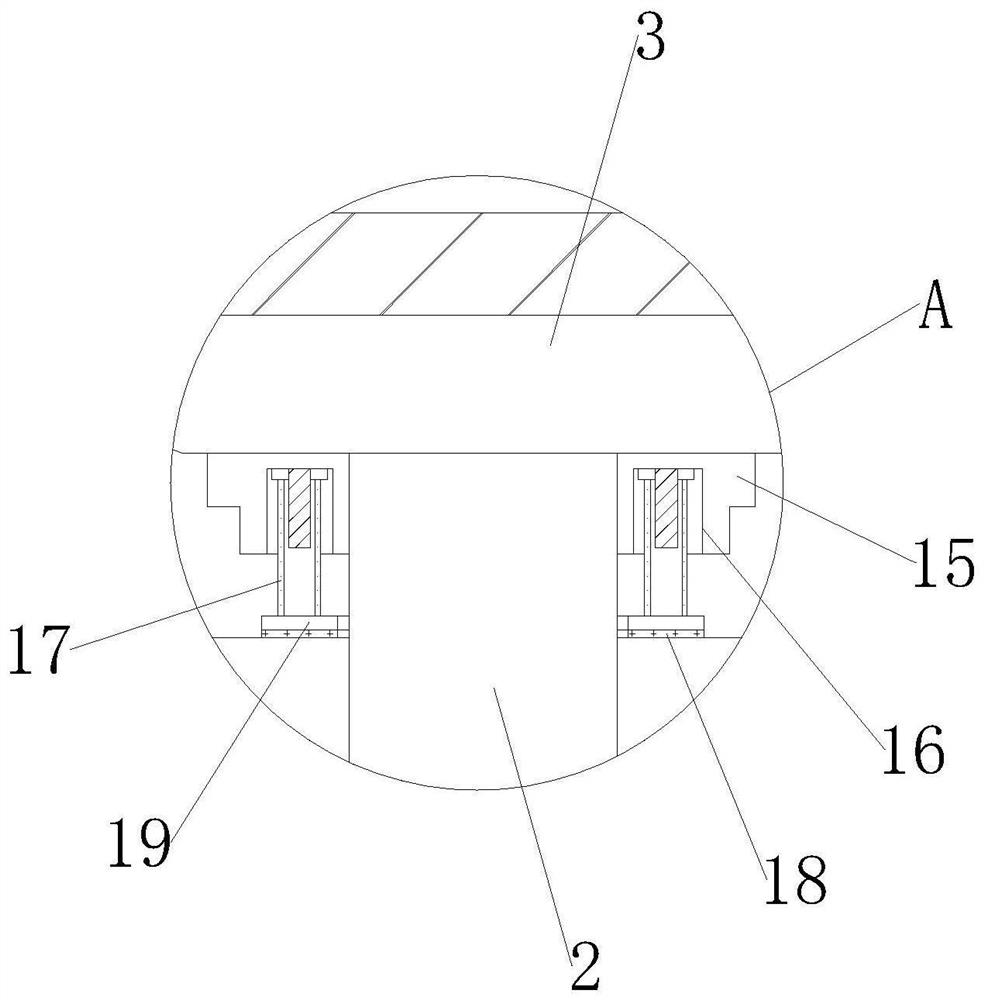

[0018] Such as Figure 1-3 As shown, a continuously variable transmission mechanism, the continuously variable transmission mechanism includes:

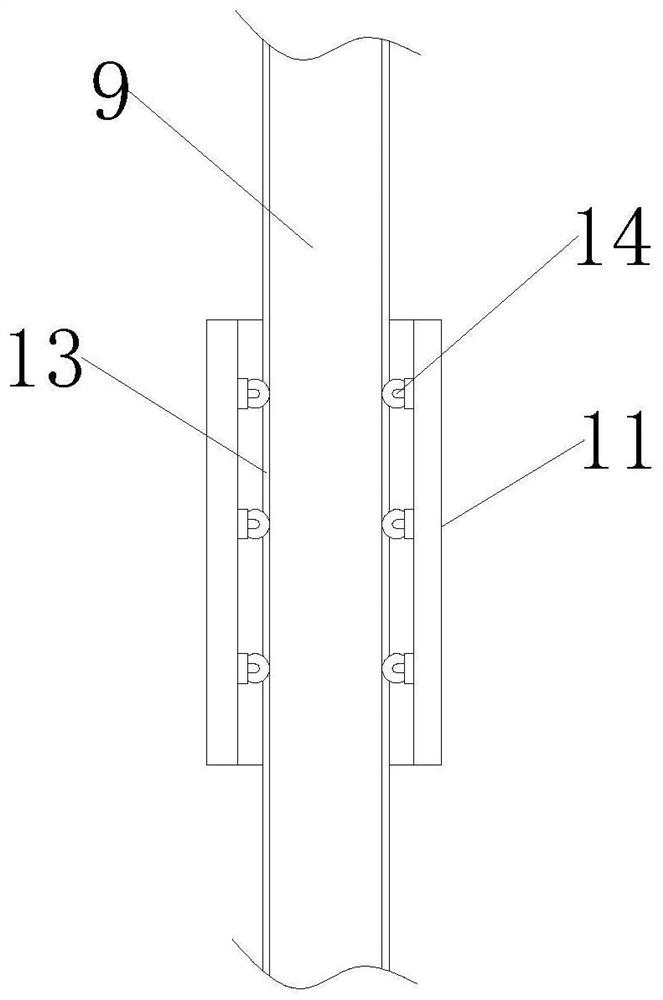

[0019] Transmission mechanism 1, a screw rod 9 is provided in the middle of the transmission mechanism 1, and chute 13 is opened on the front and rear sides of the screw rod 9, and a round tube 11 is sleeved in the middle of the outside of the screw rod 9, and the inner wall of the round tube 11 is There are several balls 14 that are rotatably connected to the front and rear sides, and the balls 14 are slidingly connected to the chute 13. The left and right ends of the screw rod 9 are threaded with a threaded ring 8, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com