Efficient plate size pass-type measuring station

A measuring station and plate technology, which is applied to measuring devices, instruments, optical devices, etc., can solve the problems of low plate measurement efficiency, inability to measure the length and width of the plate at the same time, and the plate can not keep up with the sealing speed. Achieve the effect of improving measurement efficiency, reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

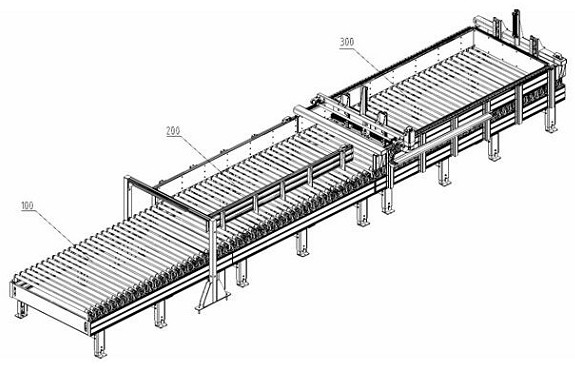

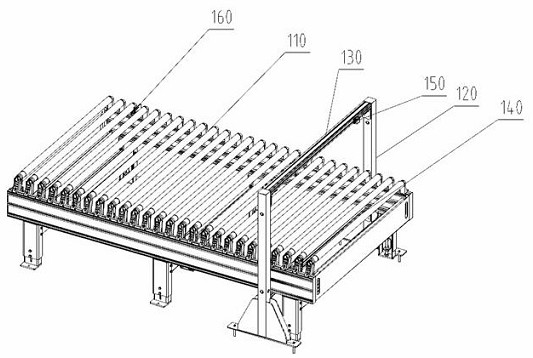

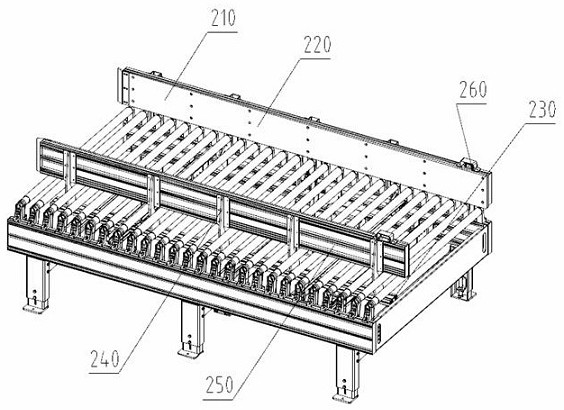

[0031] see Figure 1 to Figure 8 In view of this, the present invention provides a high-efficiency panel size through-type measuring station, the main body of which includes a panel pre-measurement mechanism 100 , a width measurement mechanism 200 and a length measurement mechanism 300 . The plate pre-measurement mechanism 100 first roughly measures the width and length of the plate, and then the width measuring mechanism 200 and the length measuring mechanism 300 accurately measure the width and length of the plate to obtain the precise size of the plate.

[0032] Specifically, the panel pre-measurement mechanism 100 includes a pre-measurement conveying roller line 110, which is placed horizontally on the ground, and several rollers parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com