Air-gap-free semi-closed backflushing comprehensive arc extinguishing lightning arrester without air gap

A semi-closed, arrester technology, applied in the field of arresters, can solve the problems of poor arc extinguishing and lightning protection, poor durability, and weak arc extinguishing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

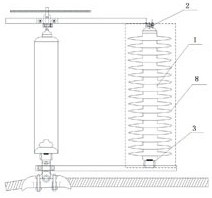

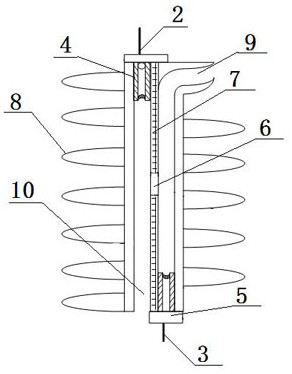

[0048] Such as Figure 2-4 As shown, a non-air gap semi-closed recoil integrated arc-extinguishing arrester includes an arrester main body 1; the upper and lower ends of the arrester main body 1 are respectively installed on the two ends of the insulator string through connecting fittings to form a reliable electrical connection; The interior of the arrester main body 1 is hollow, and an insulating partition 7 is arranged longitudinally along the arrester main body 1 so that two independent arc extinguishing chambers 10 are formed inside the arrester main body 1; The flushing device 4 has a recoil opening at the lower end; the top electrode 2 is provided at the top of the recoil device 4; a jet airflow device 5 is provided inside the lower end of the arc extinguishing chamber on the right side, and an air jet device 5 extending outward is provided at the upper end. The airflow nozzle 9; the bottom of the jet airflow device 5 is provided with a lower electrode 3; the insulating...

Embodiment 2

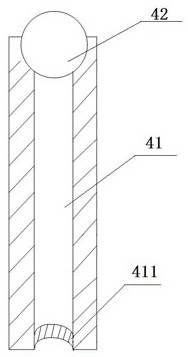

[0053] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the opening of the recoil tube 41 is provided with an arc guide ring I 411 ; the opening of the spray tube 52 is provided with an arc guide ring II 521 . The wall electrode 6 adopts a compressed arc extinguishing tube, and the inside of the compressed arc extinguishing tube is provided with an arc guiding ball

Embodiment 3

[0055] Such as Image 6 As shown, the difference between this embodiment and Embodiment 2 is that the wall electrode 6 uses a recoil tube. The recoil pipe is a semi-closed pipe with one end open and the other end connected to the lightning pole. The outer surface of the arrester body 1 is provided with several skirts 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com