Inspection robot charging pile outage emergency disposal method

A technology for inspection robots and emergency response, applied in the field of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

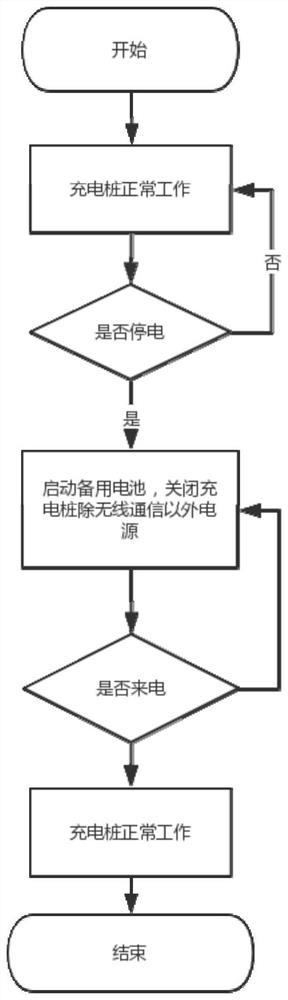

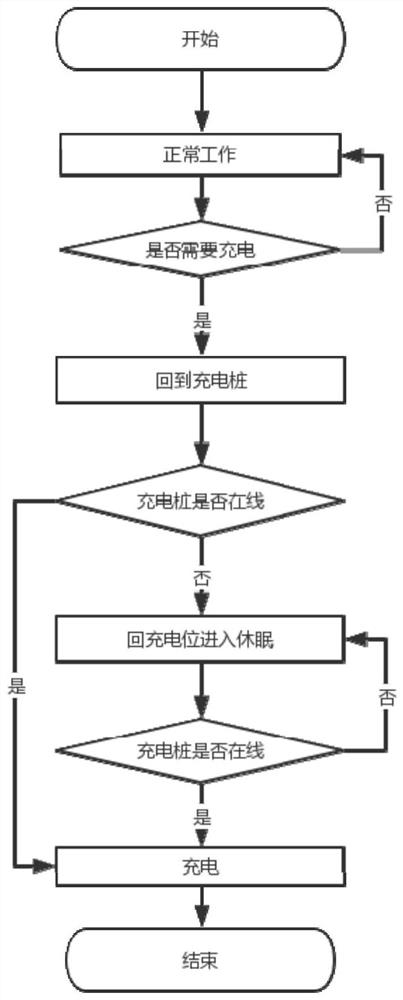

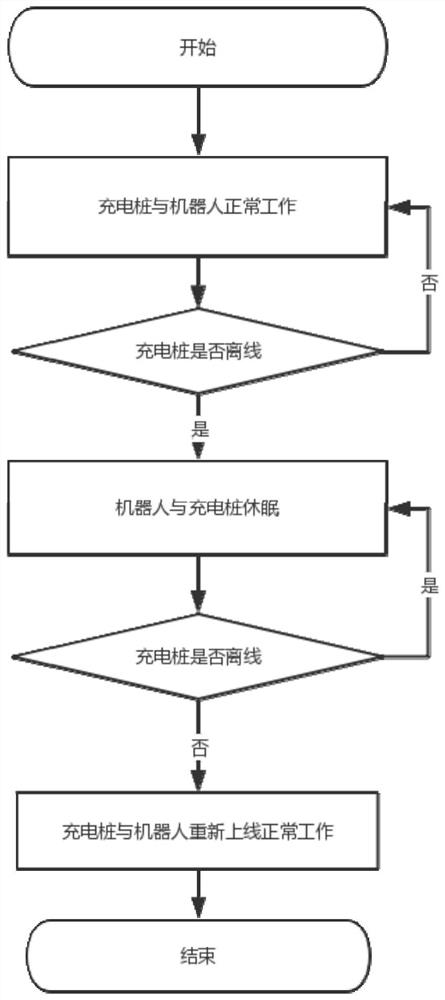

[0010] refer to image 3 , the emergency response method for patrol robot charging pile power failure, when the charging pile is powered off, switch to the built-in backup battery of the charging pile to ensure that the main board of the charging pile and the wireless communication module of the charging pile work, and the charging pile will pass through the wireless communication module of the charging pile The offline status signal is sent to the robot; when the robot returns to the charging pile for charging, the robot enters the sleep mode after receiving the offline status signal sent by the charging pile; after the charging pile sends an online signal, the robot enters the charging mode.

[0011] The charging pile uses voltage detection to determine whether the charging pile is offline. Among them, the charging pile can use voltage detection components or devices to detect the voltage of the power input end of the charging pile, and send the detection result to the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com