Automatic lifting blending device

An automatic lifting and mixing technology, applied in the directions of shaking/oscillating/vibrating mixers, mixers, transportation and packaging, etc., can solve the problems of large defects, contaminated samples, surface damage of the cuvette, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

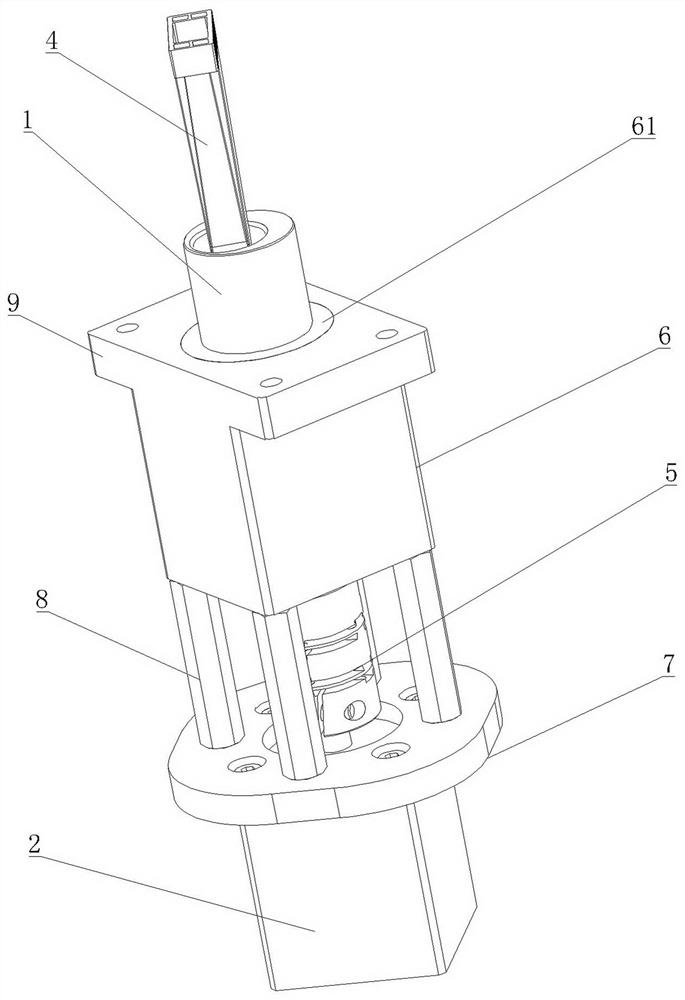

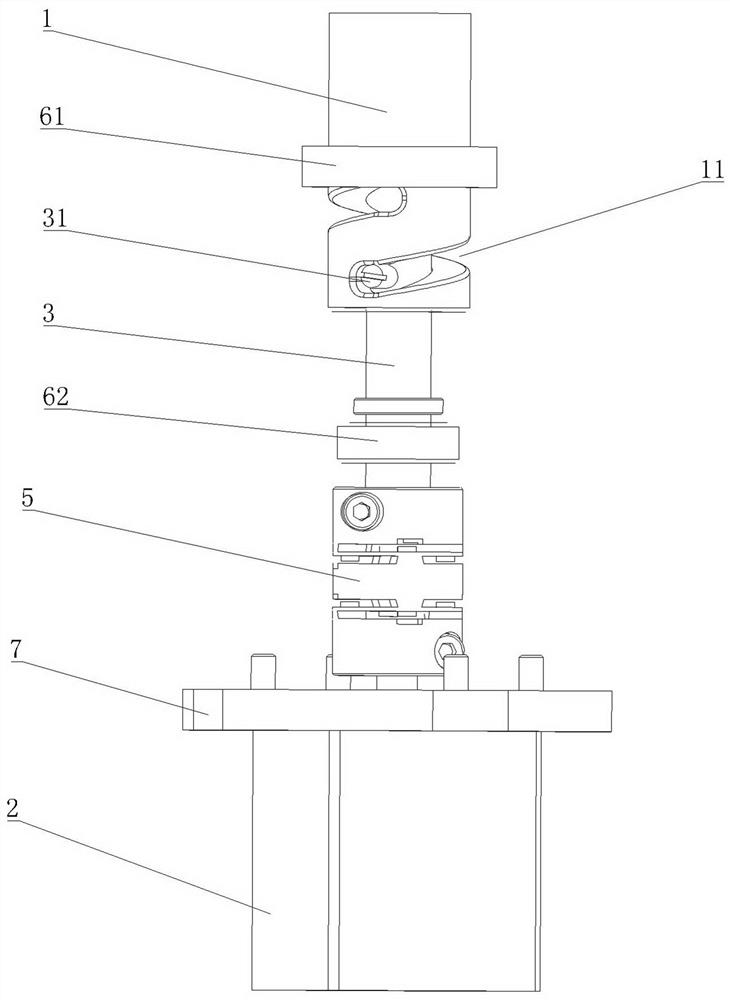

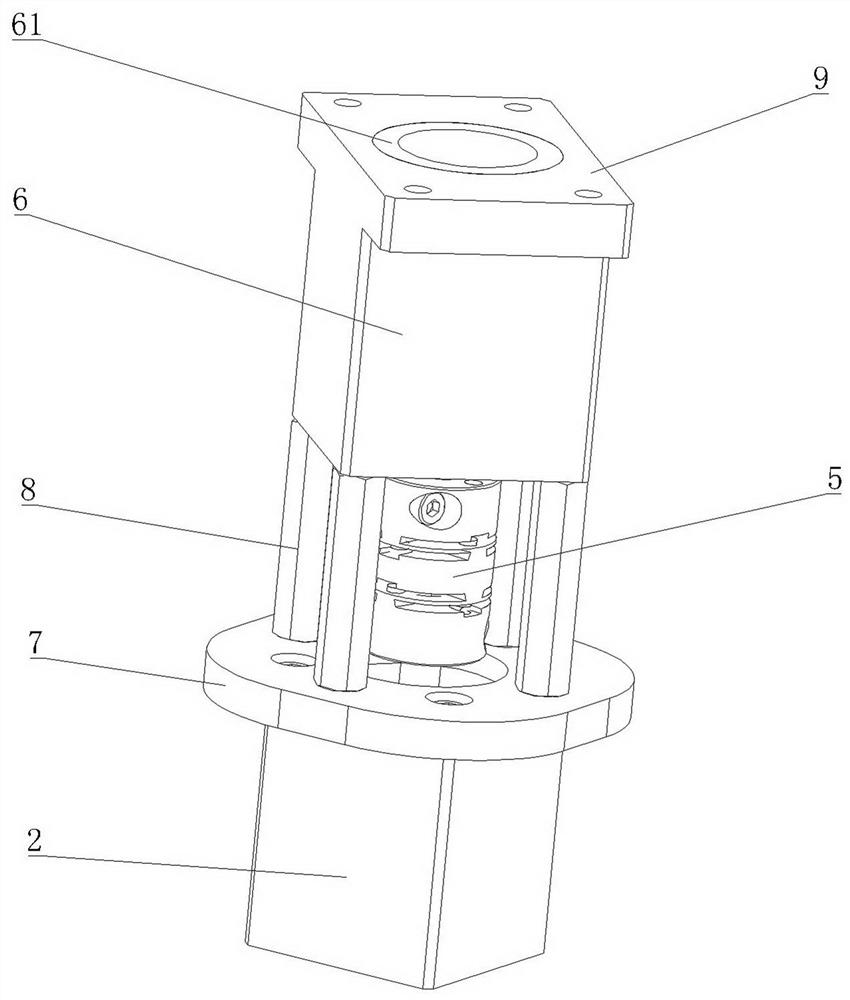

[0031] Embodiment 1: as attached Figure 1-8 As shown, an automatic lifting and mixing device includes a mixing head 1. The shape of the mixing head 1 is cylindrical. The mixing head 1 is connected with a positioning guide mechanism. Chute 11, the chute 11 is spirally arranged along the circumferential direction of the mixing head 1, the length of the chute 11 expanded is greater than the length of the outer circumference of the mixing head 1, the length of the chute 11 can be adjusted according to the needs, and the height of the chute 11 passes It is calculated that the vertical height of the chute 11 sliding along the pin shaft 31 is the rising or falling height of the mixing head 1, and the vertical height of the chute 11 is set as high as the vertical movement distance of the mixing head 1 is required. In the embodiment, due to the needs of the complete machine, the height set is 8mm, and the vertical height of the chute 11 is correspondingly set to 8mm. A pin 31 that can...

Embodiment 2

[0046] Embodiment 2: the chute 11 is a groove located on the inner wall of the first connection hole 12, the chute 11 is not in the form of a through groove, and the chute 11 is not connected with the outside world, so the pin shaft 31 can be pre-installed on the transmission shaft 3, the pin shaft 31 is connected to the transmission shaft 3 through elastic components, after the pin shaft 31 is compressed so that the pin shaft 31 is installed in the chute 11, the pin shaft 31 will return to its original position through the elastic component, and the transmission shaft 3 rotates, driving the pin shaft 31 rotation can also realize the lifting and mixing of the mixing head. It is also possible to process a round hole connected with the chute 11 on the mixing head 1. The pin shaft 31 can pass through the round hole, and the pin shaft 31 can be passed through the round hole. Threaded connection with the transmission shaft 3, after the pin shaft 31 is connected with the transmission...

Embodiment 3

[0048] Embodiment 3: The chute 11 is a groove located on the outer peripheral surface of the mixing head 1, the end of the transmission shaft 3 connected to the chute 11 is provided with a sleeve, the pin shaft 31 is arranged in the sleeve, and one end of the pin shaft 31 is Located in the chute 11, the other end of the pin shaft 31 can be fixedly connected to the sleeve. The pin shaft 31 can be connected to the sleeve through an elastic device, threaded, or welded. This form can also realize the pin The shaft 31 drives the lifting and rotation of the mixing head 1 .

[0049] All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com