Straddle type monorail system adapting to different gradients by adjusting wheeltrack acting force

A technology of wheel-rail force and straddle-type monorail, which is applied in the direction of monorail system, prevention of railway derailment, railway car body parts, etc., and can solve problems such as difficult to apply to large-slope lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

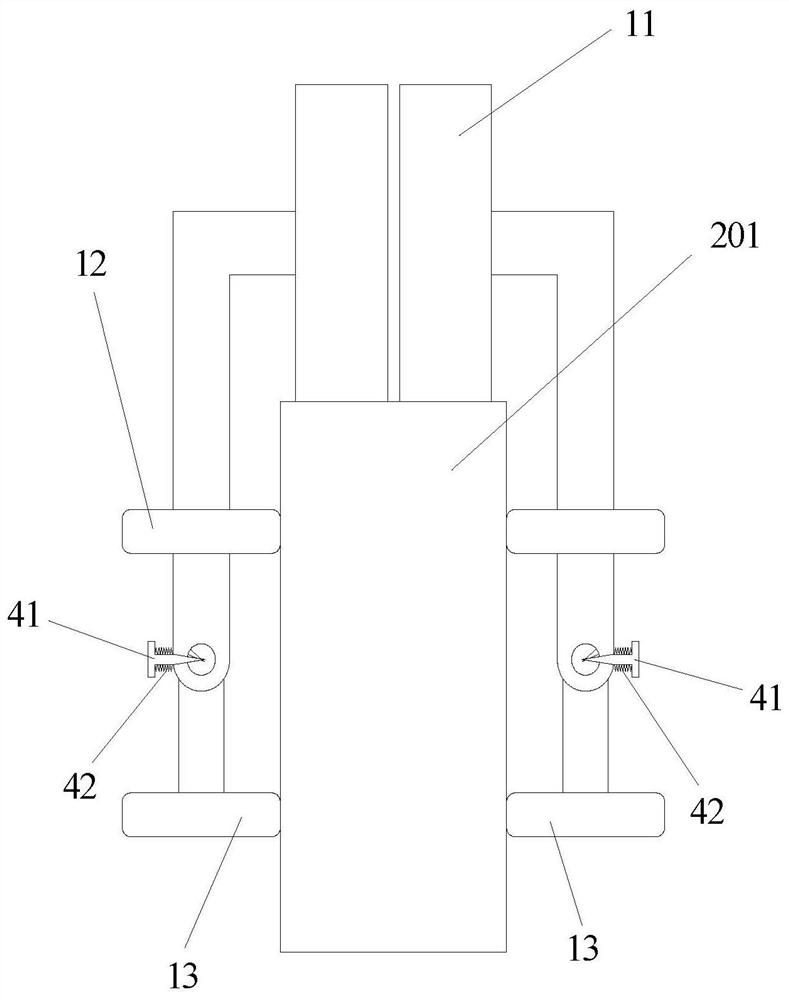

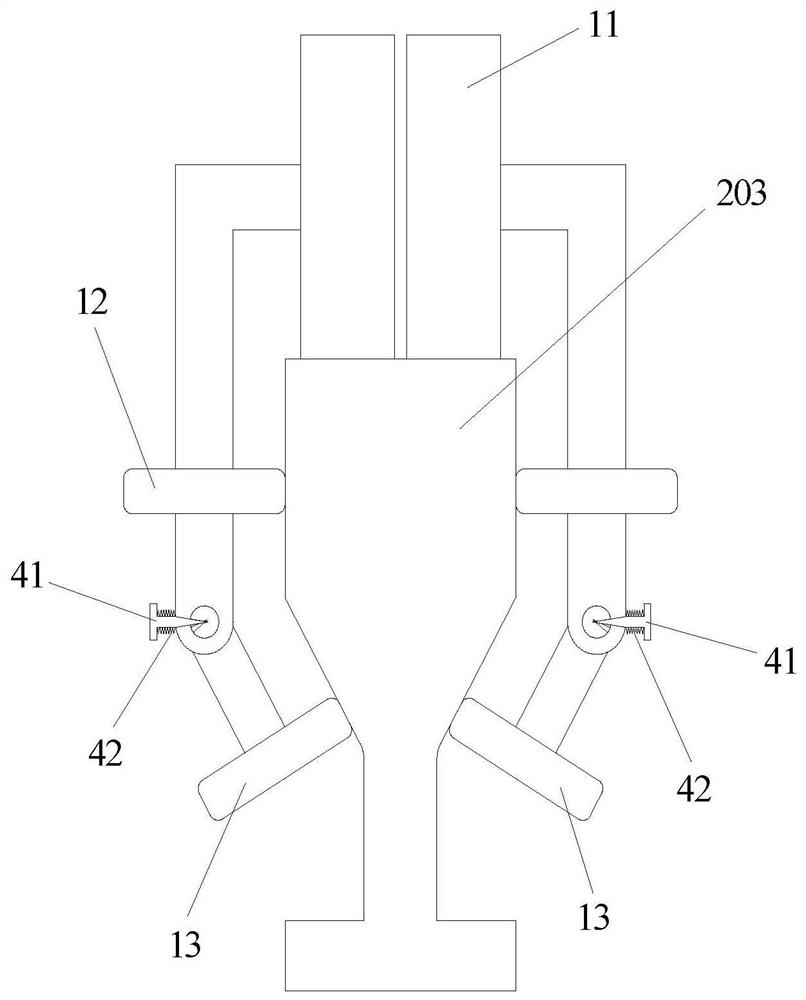

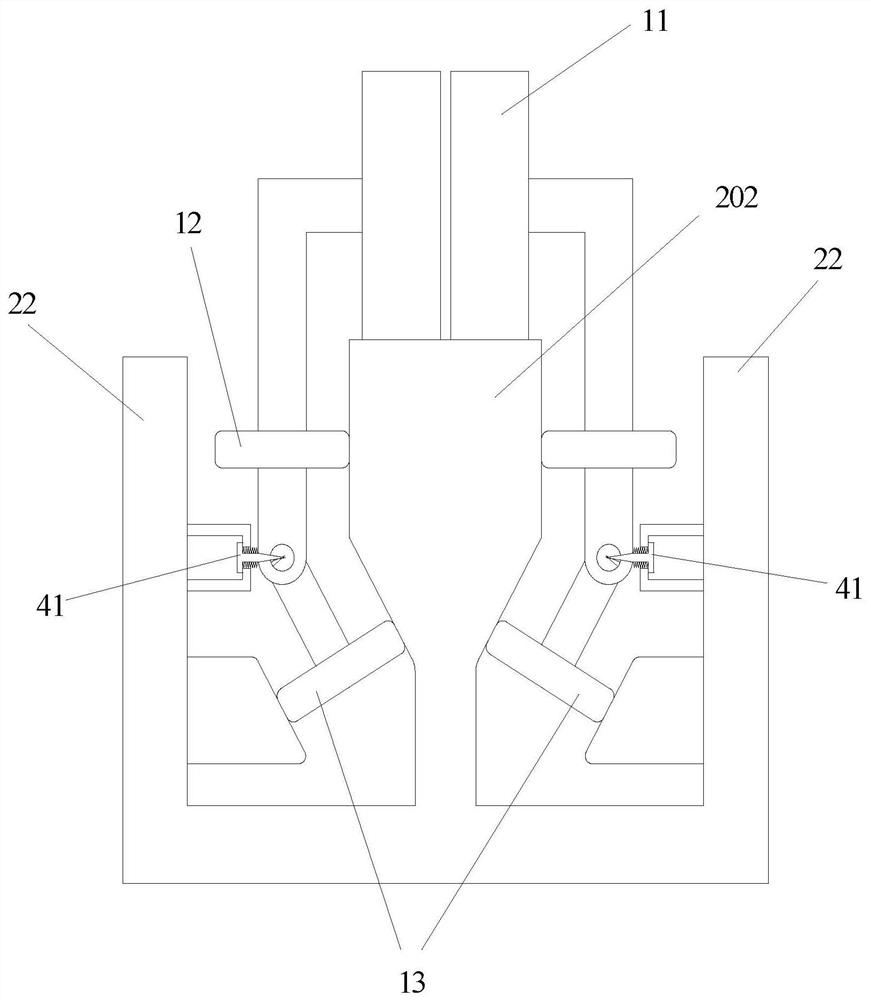

[0049] A straddle-type monorail system adapted to different slopes by adjusting the wheel-rail force according to the present invention, comprising:

[0050] The bogie is located on the beam body. The bogie includes traveling wheels 11, guide wheels 12 and stabilizing wheels 13. The guide wheels 12 are arranged above the stabilizing wheels 13. Between the guiding wheels 12 and the stabilizing wheels 13 hinged connection between

[0051] Beam body, the beam body includes a running surface, a guiding surface and a stable surface, when the slope of the running surface of the beam body is greater than or equal to 100‰, the stable surface of the beam body is set inwardly from top to bottom;

[0052] A pressure adjustment device is connected to the beam body, and the pressure adjustment device can increase or decrease the pressure of the stable wheel 13 relative to the stable surface so that the running wheel 11 can move relative to the running surface pressure increases or decreas...

Embodiment 2

[0062] like Figure 11 As shown in the present invention, a straddle-type monorail system that adapts to different slopes by adjusting the force of the wheel and rail, its structure is roughly the same as that of Embodiment 1, the difference is that the bogie is provided with grooves For example, two snap rings are provided on the articulated arm of the guide wheel 12, the two snap rings are socketed with a gap between them, and the gap forms the groove. A sleeve 43 is arranged between the pin 41 and the spring 42, and the sleeve 43 is arranged and connected to the groove, and the sleeve can slide along the groove to facilitate positioning of the pin 41. It is further ensured that the pin 41 can be smoothly inserted into the slot. The side wall of the end cap of the pin 41 has a rolling bearing 44, and the rolling bearing 44 is used to roll and connect the positioning groove, changing sliding friction into rolling friction, making the pin 41 more likely to slide along the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com