A process device and method for self-cleaning high-temperature oil and gas filtration and dust removal

A technology for filtration and dust removal and process equipment, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of difficult backflushing and regeneration, prone to breakage, large process gas volume, etc., to ensure long-term stable operation, The effect of easy maintenance and repair and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

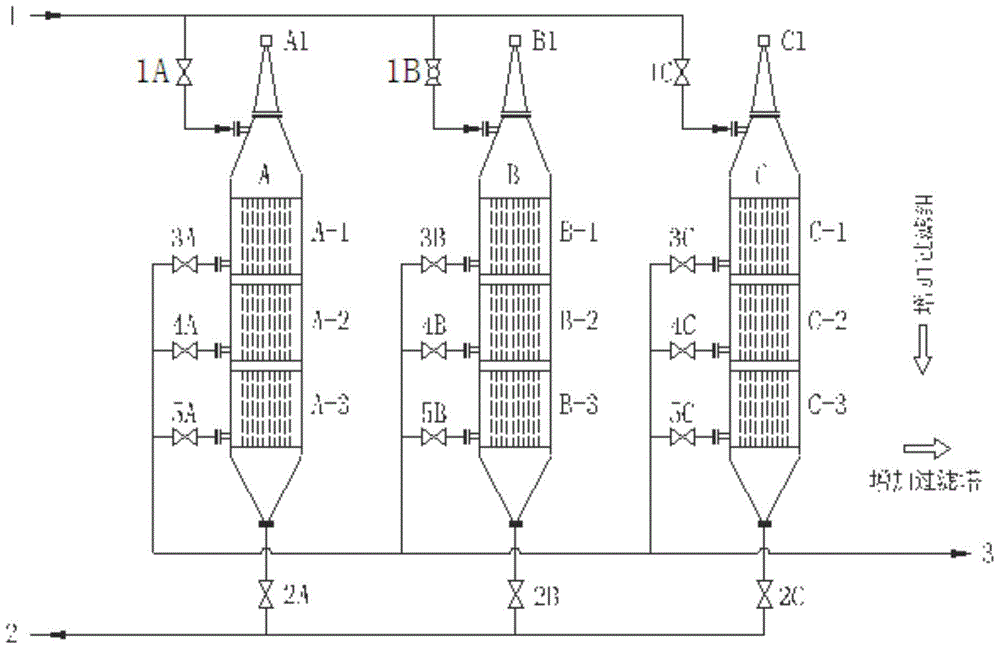

[0052] see Figure 1 to Figure 3 , a process method for self-cleaning high-temperature oil and gas filtration and dust removal based on the process device, comprising the following steps:

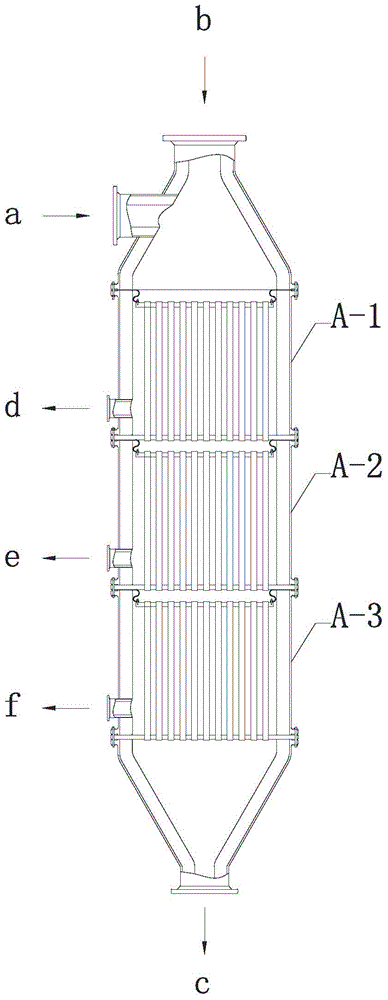

[0053] 1. The 800°C high-temperature oil and gas 1 from a known pyrolysis device is distributed to filter towers A, B, and C through pipelines. Due to the parallel operation of the filter towers, the process is described by taking Tower A as an example.

[0054] 2. High-temperature oil and gas 1 enters tangentially from the high-temperature oil-gas interface on the top side of filter tower A through feed gas cut-off valve 1A. The high-temperature oil and gas 1 flows from top to bottom inside the filter tower A, and passes through the tower filter groups A-1, A-2, and A-3 for purification. During this process, most of the gas penetrates through the inner surface of the filter element, and the temperature of the purified gas drops to 760°C due to the heat dissipation effect of the pipeline ...

Embodiment 2

[0059] see Figure 1 to Figure 3 , a process method for self-cleaning high-temperature oil and gas filtration and dust removal based on the process device, comprising the following steps:

[0060] 1. The 520°C high-temperature oil and gas 1 from the known pyrolysis device is distributed to filter towers A, B, and C through pipelines. Due to the parallel operation of the filter towers, the process is described by taking Tower A as an example.

[0061] 2. High-temperature oil and gas 1 enters tangentially from the high-temperature oil-gas interface on the top side of filter tower A through feed gas cut-off valve 1A. The high-temperature oil and gas 1 flows from top to bottom inside the filter tower A, and passes through the tower filter groups A-1, A-2, and A-3 for purification. During this process, most of the gas passes through the inner surface of the filter element, and the temperature of the purified gas drops to 470°C due to the heat dissipation effect of the pipeline an...

Embodiment 3

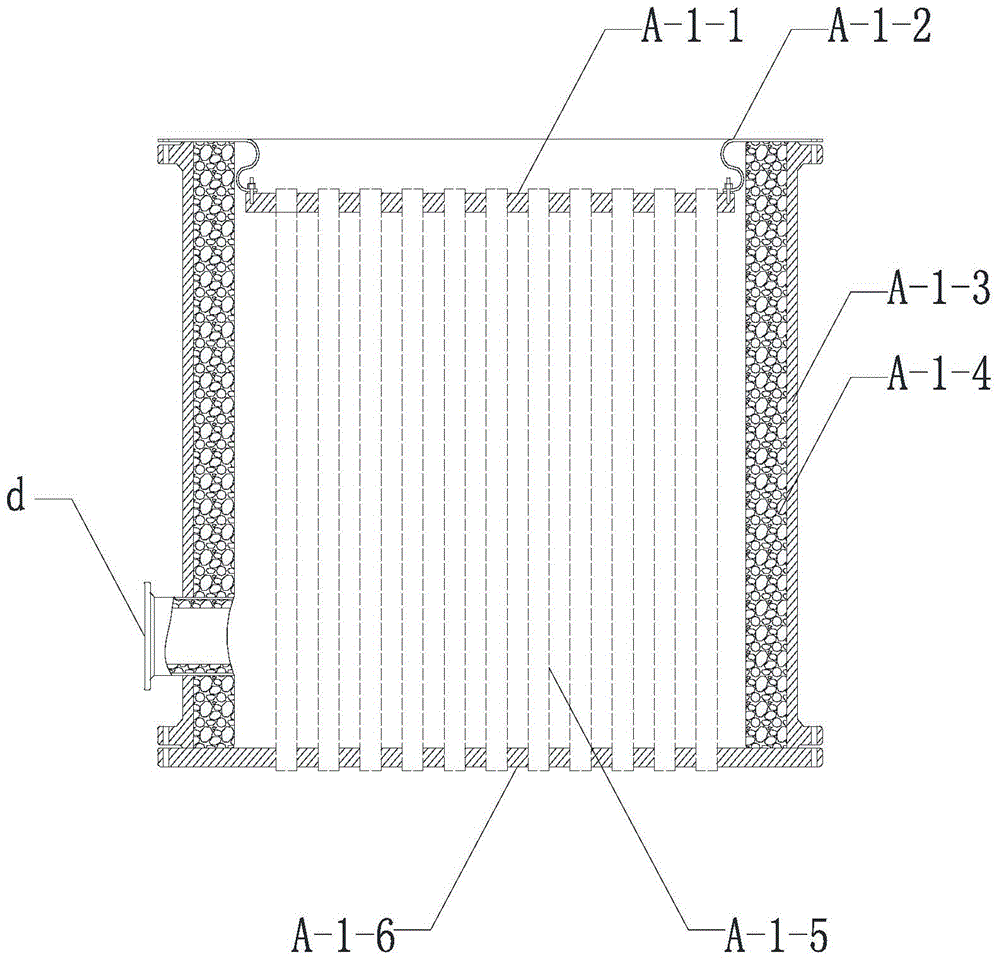

[0066]The 650°C high-temperature oil and gas 1 from the double-circulating fluidized bed pyrolysis unit is distributed through pipelines to three filter towers A, B, and C operating in parallel. Now take tower A as an example to describe the process. High temperature oil gas 1 enters from the top of filter tower A in a conical shape through feed gas cut-off valve 1A. The high-temperature oil and gas 1 flows from top to bottom inside the filter tower A, and passes through the tower filter groups A-1, A-2, and A-3 in sequence. According to the particle size characteristics of high-temperature oil and gas dust, the filter elements of tower filter groups A-1, A-2, and A-3 (for example, the filter element of tower A-1 tower filter group is A-1-5) select the inner surface of the filter element membrane The metal multi-layer sintered mesh for filtering, the filter element (A tower A-1 tower filter group as an example, the filter element is A-1-5) has a filtration accuracy of 30 micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com