Guard plate device for train, train and rail transit system

A technology for trains and guard plates, applied in the field of trains and rail transit systems, can solve problems affecting the normal use of the guard plate structure, wear and tear of the guard plate structure, and complex structure of the guard plate, so as to improve the appearance, reduce internal wear, and improve The effect of passenger comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

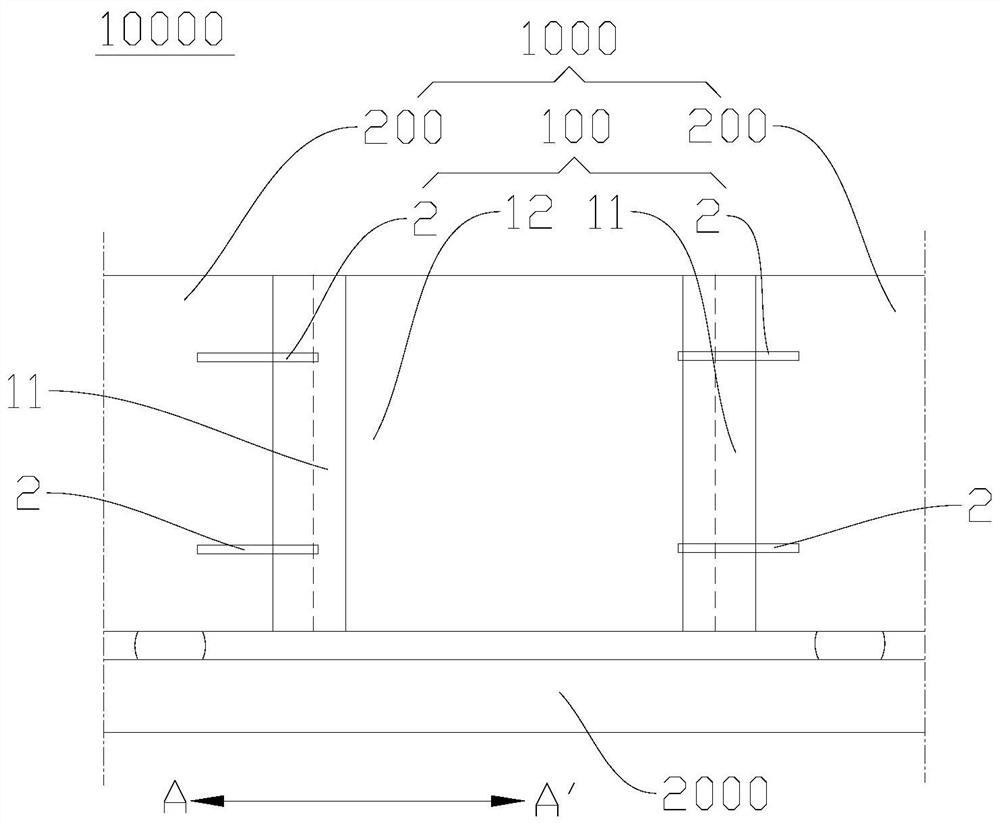

[0098] In this example, if Figure 3-Figure 7 As shown, the fender device 100 includes a fender assembly 1 and a sliding assembly 2 .

[0099] The guard plate assembly 1 comprises two second guard plates 11 and a first guard plate 12, in the length direction of the train 1000 (for example, image 3 with Figure 4 In the AA' direction), the width of the first guard plate 12 is greater than the width of the second guard plate 11, the two second guard plates 11 are stacked with the first guard plate 12, and the two second guard plates 11 are arranged at intervals On both sides of the first guard plate 12 , and two second guard plates 11 are stacked inside the first guard plate 12 , and the two second guard plates 11 are respectively fixedly connected to the adjacent side body 200 through the bracket 10 .

[0100] There are four sliding assemblies 2, and two sliding assemblies 2 are respectively arranged on the above-mentioned two sides of the first guard plate 12, and the two s...

Embodiment 2

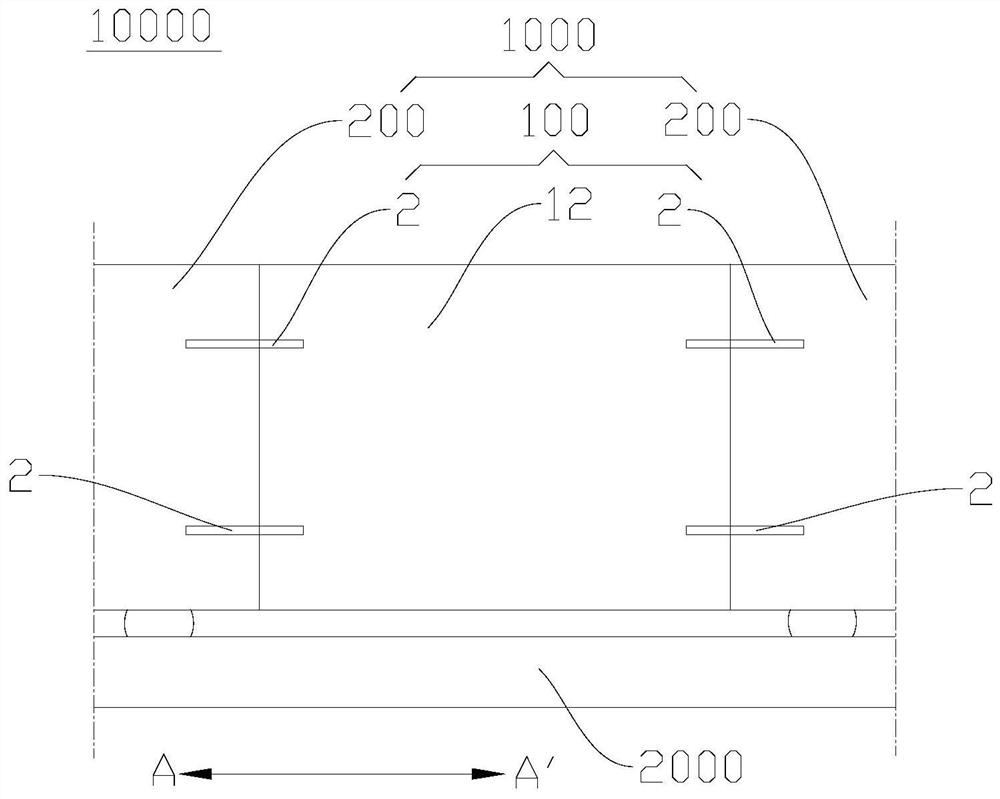

[0109] Such as figure 1 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that: the guard plate assembly 1 includes a first guard plate 12, and the guard plate assembly 1 is not provided with a first guard plate 12 Two guard plates 11.

Embodiment 3

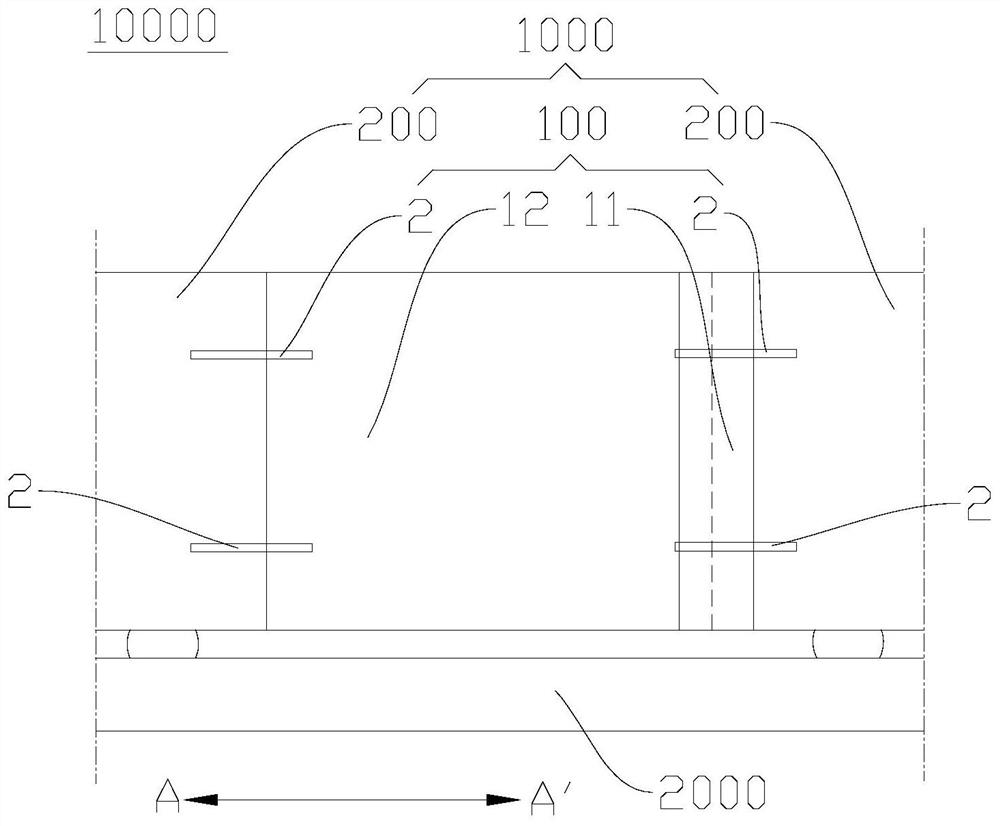

[0111] Such as figure 2 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that there is one second guard plate 11, and the second guard plate 11 is arranged on the first guard plate 12 on one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com