Undercarriage aerodynamic load test device and design method thereof

A technology of aerodynamic load and test device, which is applied in the directions of ground installation, transportation and packaging, aircraft component testing, etc., can solve problems such as failure to meet the test requirements, and achieve the effects of convenient implementation, high reliability, and easy repeated disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

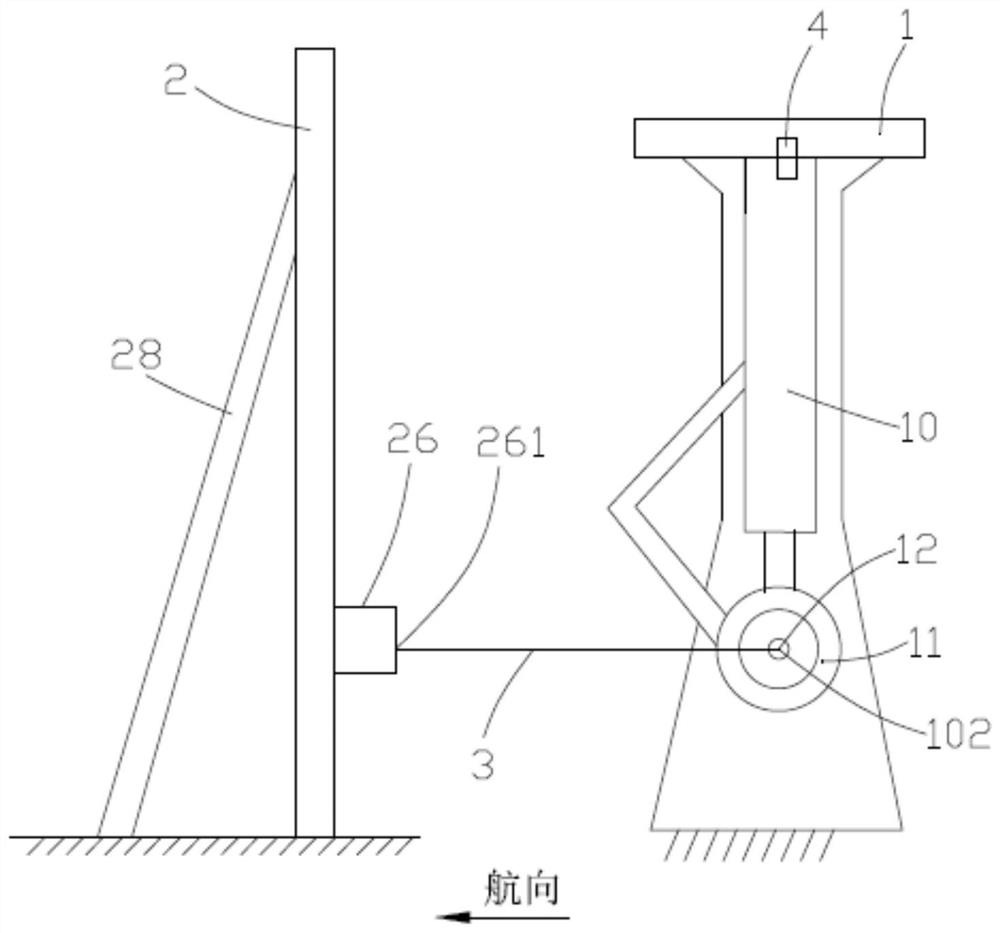

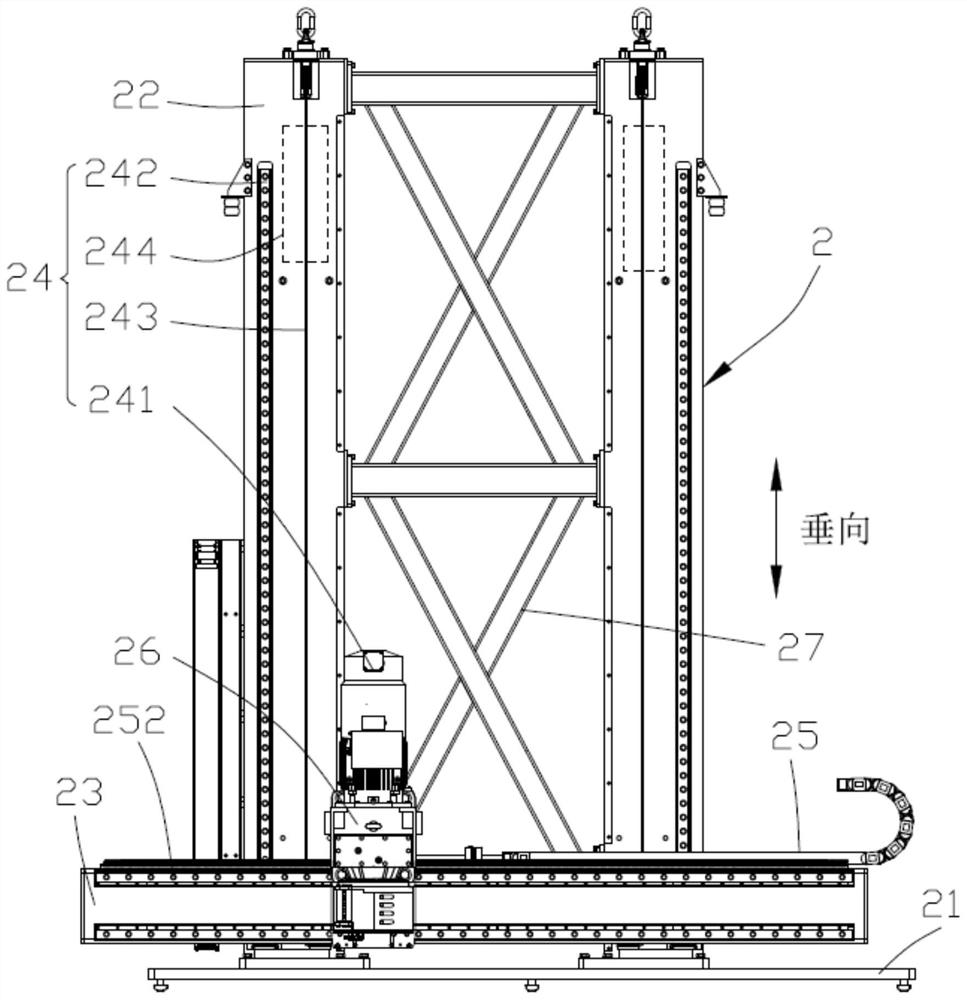

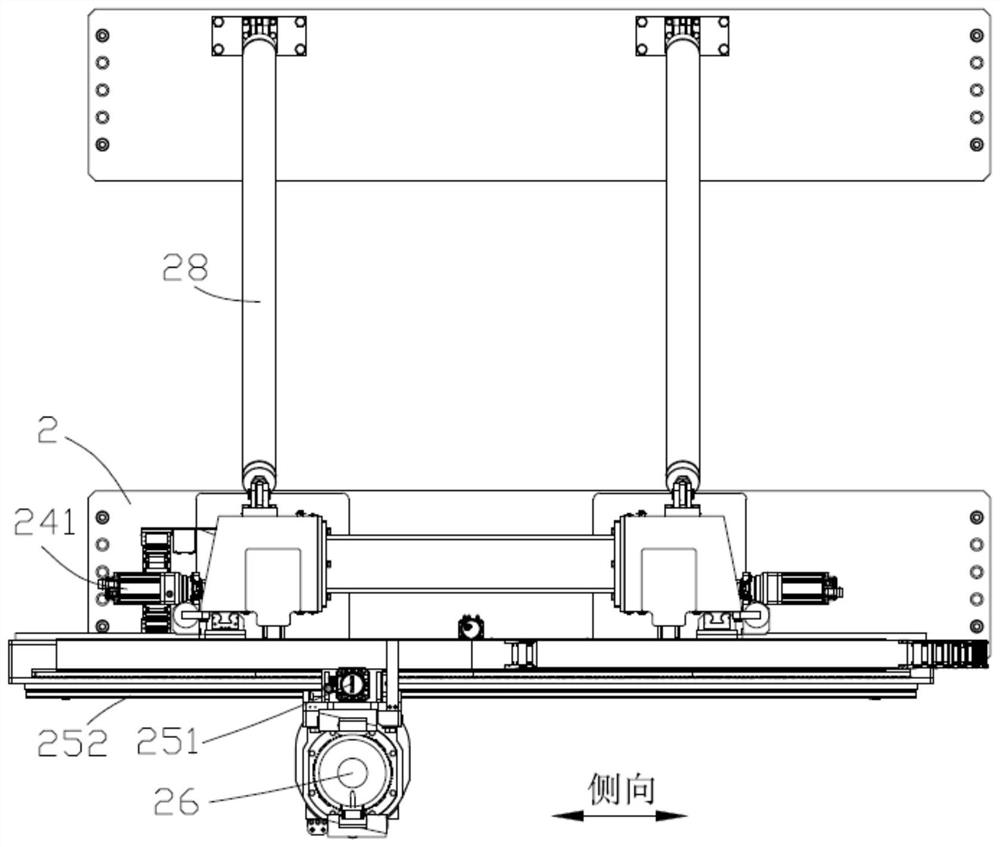

[0032] Such as Figure 1~3 As shown, a landing gear aerodynamic load test device provided in this embodiment includes a mounting frame 1 , a loading device 2 , a loading wire rope 3 , an angle sensor 4 and a mounting support 5 .

[0033] The mounting frame 1 is used to fix the landing gear 10 . The main shaft of the undercarriage 10 is fixed to the upper end of the mounting frame 1 by bolts. The dummy wheel assembly 11 is provided on the mounting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com