Lifting transposition device for long-neck bottle

A long-necked bottle and transposition technology, which is applied in the direction of packaging, packaging bottles, transportation and packaging, etc., can solve the problem of inconvenient transfer of bottles, avoid direct extrusion with glass rigidity, and improve work efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

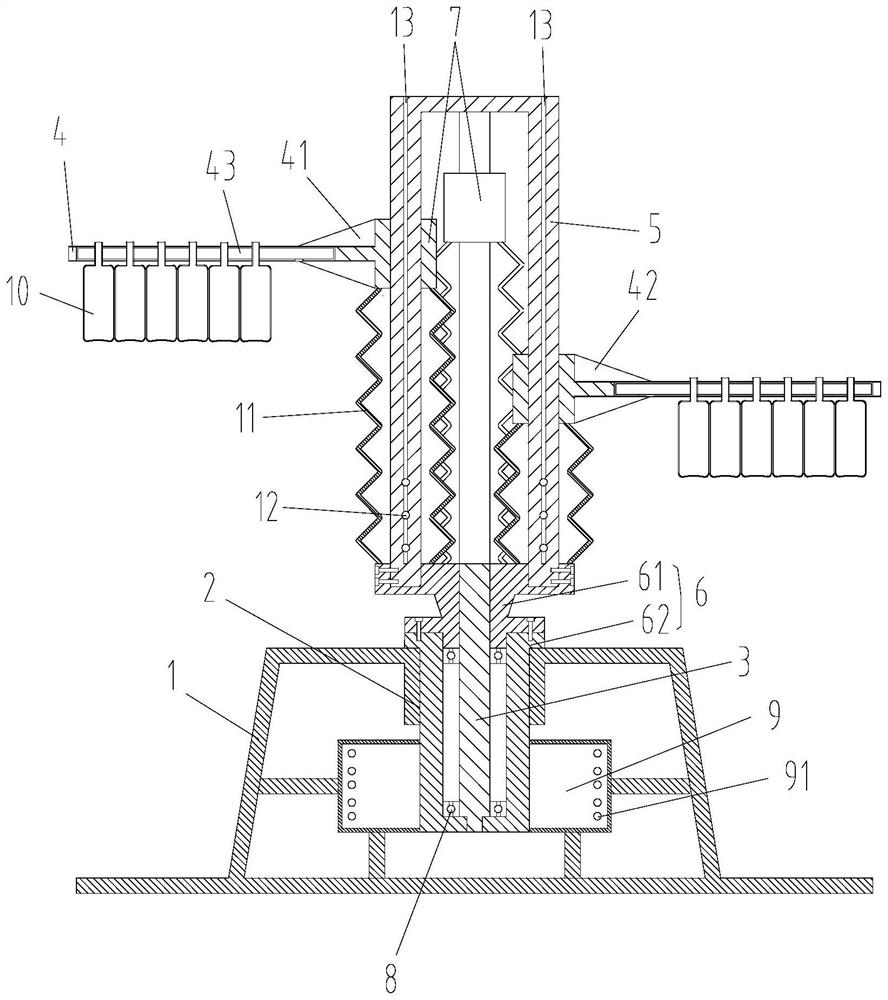

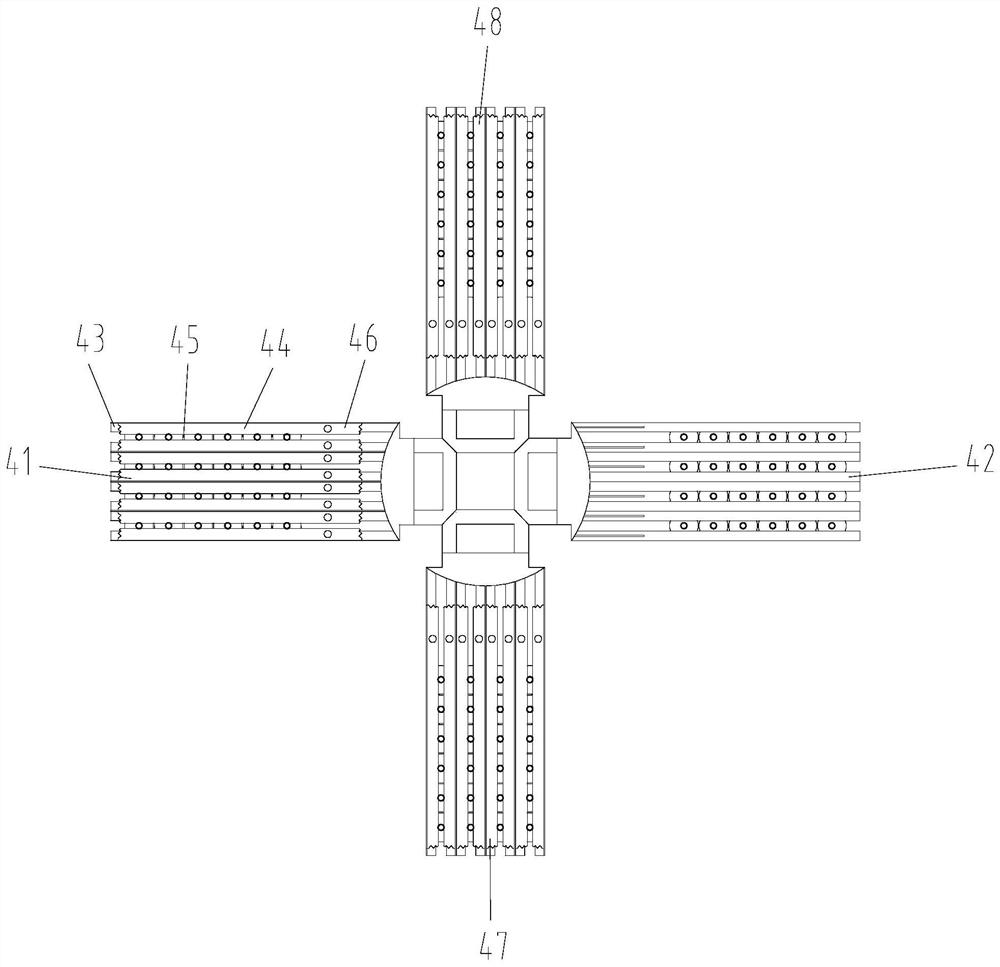

[0018] Embodiment 1, the present invention provides a kind of long-necked bottle lifting and transposition device, such as figure 1 As shown, it includes a base 1, the top of the base 1 is provided with a first groove 2, a fixed shaft 3 is installed in the first groove 2, the fixed shaft 3 is provided with a hollow positioning column 5, and the positioning column 5 passes through the positioning seat 6 Fixed on the base 1, the positioning column 5 has a groove on all four sides along the shaft direction, and a positioning cover 7 is installed in each groove. The positioning cover 7 can move up and down along the groove, and the inside of the positioning column 5 along the A rubber telescopic sleeve 11 is provided on each of the four sides of the axial length direction. One end of each rubber telescopic sleeve 11 is against the bottom of the positioning cover 7, and the other end is against the inner bottom of the positioning column 5. There is an air outlet 12, and the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com