Iron nail box loading machine

A cartoning machine and iron nail technology, which is applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of iron nails easy to fall from the hand, low work efficiency, laborious and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

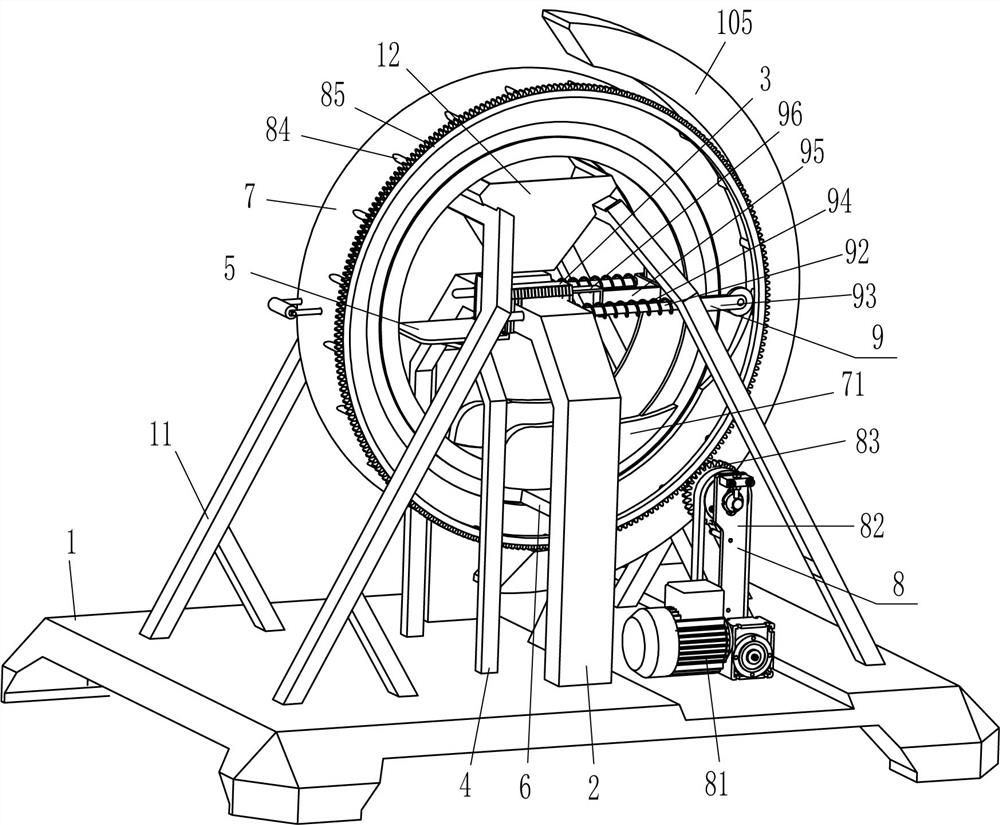

[0023] A nail cartoning machine, such as figure 1 As shown, it includes a base 1, an L-shaped plate 2, an electromagnet 3, a supporting plate 4, a placement plate 5, a guide block 6, a ring frame 7, a driving plate 71, a driving mechanism 8 and a pushing mechanism 9, and the top middle of the base 1 L-shaped plates 2 are fixedly connected to the front and rear sides, electromagnets 3 are fixedly connected to the inner ends of the L-shaped plates 2 on the front and rear sides, and the electromagnets 3 on the front and rear sides are matched with each other. 4. A placement plate 5 is fixed between the inner ends of the front and rear support plates 4 to allow the box to be placed. The placement plate 5 is located on the left side of the electromagnet 3 on the front and rear sides. The material mechanism 9, the front and rear sides of the L-shaped plate 2 are fixedly connected to the lower part of the inner side of the guide block 6, and the ring frame 7 is slidably provided betwee...

Embodiment 2

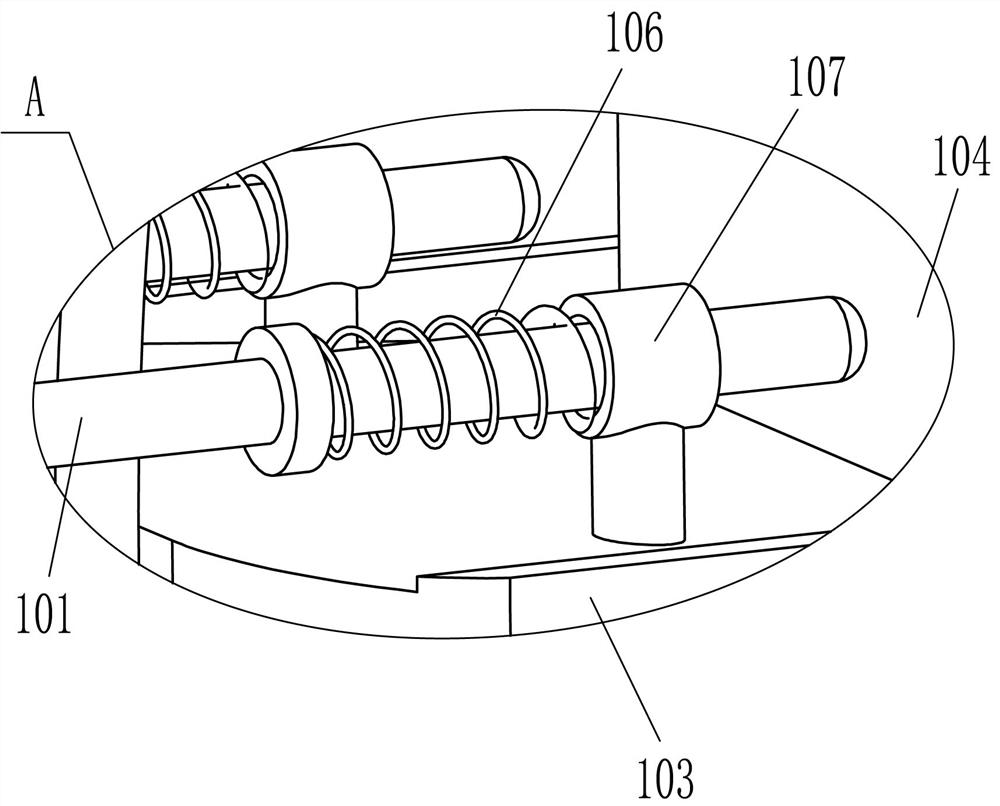

[0030] On the basis of Example 1, such as Figure 1-Figure 3 As shown, the conveying mechanism 10 is also included. The conveying mechanism 10 includes a sliding rod 101, a contact wheel 102, a baffle 103, a swing plate 104, an arc block 105, a second spring 106, and a guide sleeve 107. The left side of the ring frame 7 The middle part is symmetrically slidable through the sliding rod 101. The left ends of the front and rear sliding rods 101 are rotatably connected with a contact wheel 102. The right part of the sliding rod 101 is slidingly covered with a guide sleeve 107, and the left side of the guide sleeve 107 A second spring 106 is wound around the right part of the sliding rod 101. A baffle 103 is fixedly connected to the left part of the ring frame 7. The top of the baffle 103 is fixedly connected to the bottom of the front and rear guide sleeves 107, and the right end of the baffle 103 is hinged. There is a swing plate 104, an arc block 105 is installed in the middle of...

Embodiment 3

[0033] On the basis of Example 1 and Example 2, such as figure 1 , figure 2 with Figure 4 As shown, it also includes a support frame 11 and a lower hopper 12. The bottom left and right sides of the top of the base 1 are symmetrically fixed to the front and rear with the support frame 11, and the bottom hopper 12 is fixed between the tops of the four support frames 11. The electromagnets 3 on both sides are directly above.

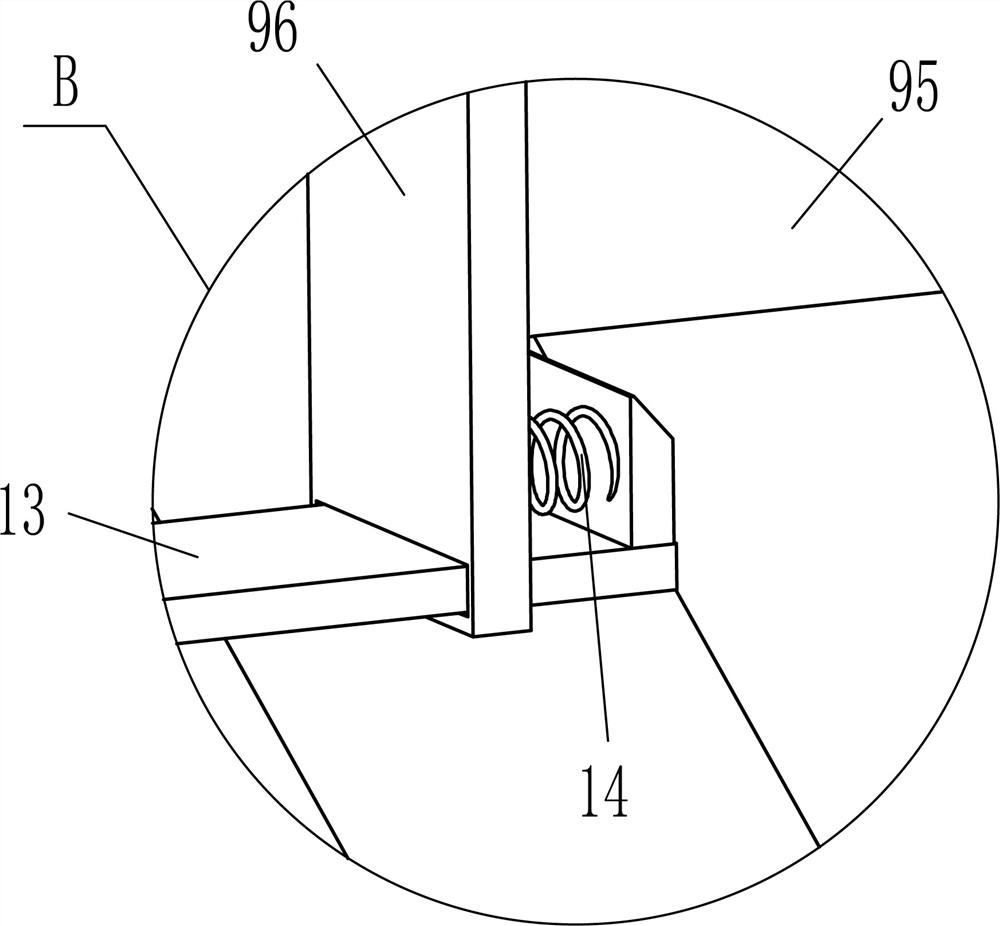

[0034] It also includes an L-shaped baffle plate 13 and a third spring 14. The lower part of the L-shaped push plate 96 is slidably connected with an L-shaped baffle plate 13, and the inner right side of the L-shaped baffle plate 13 and the L-shaped push plate 96 A third spring 14 is symmetrically connected between the lower parts of the outer right side surface.

[0035] When the swinging plate 104 swings inward without blocking the iron nails, the iron nails fall down into the lower hopper 12, and the iron nails in the lower hopper 12 fall between the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com